tkroenlein

Well-Known Member

Thirded. You've got a little edge thickness to play with to boot.I'm in agreement with Randy. That looks fixable to me. Take another look at it tomorrow

Thirded. You've got a little edge thickness to play with to boot.I'm in agreement with Randy. That looks fixable to me. Take another look at it tomorrow

Messed up another one tonight. Started chasing around a minuscule issue on a plunge and ended up over grinding pushing it way off center. This is like the fifth knife I’ve messed up in a row Haven’t all been the plunge issue but still irritating. Stuck in a rut.

Yes, looks fixable. Lets say by grinding (as shown in photo) to the left towards the center, that the width of the blade at the cutting edge is then too thin, or reduced to near zero. Can the problem of having too thin of a cutting edge be overcome by simply grind down the blade edge and ricasso flat (the red colored faxe) to widen it to the correct width, let's say .020"+/-? This may reduce the height of the blade by a small amount and may require a bit of "mid-course correction" in blade pattern shape.Messed up another one tonight. Started chasing around a minuscule issue on a plunge and ended up over grinding pushing it way off center. This is like the fifth knife I’ve messed up in a row Haven’t all been the plunge issue but still irritating. Stuck in a rut.

View attachment 75325

Yes. I'd much rather take back an edge that is too thin than to make one sharp that is too thick.Yes, looks fixable. Lets say by grinding (as shown in photo) to the left towards the center, that the width of the blade at the cutting edge is then too thin, or reduced to near zero. Can the problem of having too thin of a cutting edge be overcome by simply grind down the blade edge and ricasso flat (the red colored faxe) to widen it to the correct width, let's say .020"+/-? This may reduce the height of the blade by a small amount and may require a bit of "mid-course correction" in blade pattern shape.

Hope that makes sense.

Thanks for posting Boss. That Proxon pantograph looks very interesting. I may have to look into that.This is Alyssa, she works in our shop as a welder and fabricator. I had her weld up the Ti billet several of us made. The billet is stacked and then completely boxed in with mild steel. Every seam is welded so no oxygen gets in.

View attachment 75409

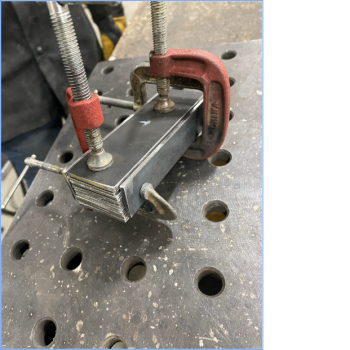

A close look at the billet before it is completely welded shut.

View attachment 75410

Here is a billet of Ti (can still on) with grooves cut in. It goes back in the heat and pressed much like ladder pattern.

View attachment 75416

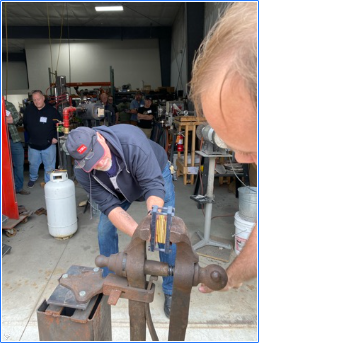

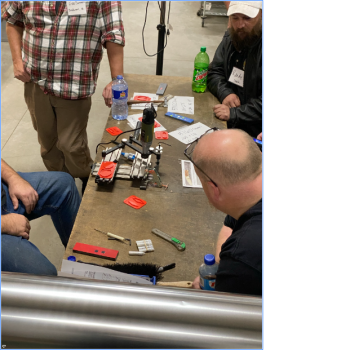

We had two classes going at once. When each session is done, the groups rotate to the other session. On the other side of the building Luke is showing the Proxon pantograph. Here Cody is showing how he lays up a damascus billet.

View attachment 75411View attachment 75412

Luke is showing the Proxon pantograph.

View attachment 75413View attachment 75414

Some examples of inlays done with the Pantograph. The blue one shows inserts. The olive color g10 shows how colored epoxy can be used in place of an inlay.

View attachment 75415

Gosh, it seems like it's taken forever, but I just finished bead blasting handles, and applying a single coat of Tru-Oil. Provided my body cooperates, a couple days of building kydex sheaths....and they should be ready to go! Stay Tuned!

Thanks! I'm still dealing with them (the health issues). Lupus, which attacked my lungs, resulting in interstitial lung disease, and a dose of firbro on top of it. God has just granted me a few more "good" days then bad ones lately.... so I try to use them wisely and get a little work done when/while I can. Sometimes it's really difficult to not fall down the hole of despair, but its folks like you, and the rest of the wonderful people here on the forums, and in the knife community, that help keep me on level ground! Most won't ever realize how they said (typed) a kind, encouraging word to me.... when I was hanging on the edge.... and needed it the most.When I first joined this forum you were dealing with health issues. Good to see you active making knives again.

Last Saturday we hosted a Midwest Knifemakers Guild meeting at our shop. If you aren't in a guild, join one. If you don't have a guild close to you start one. These are all about exchanging knowledge and techniques and making friends.

.

Peter Martin demo's making Mokume.

View attachment 75402View attachment 75403

Did you happen to video the mokume process? I always like to see how others make theirs.