Justin Presson

Well-Known Member

Hey guys, there is a thread like this on another forum and I know some of you know what I'm talking about. I just thought I would try to get one started here in KD.

Just post up anything you might be working on. Hopefully we can keep it going.

I'm just excited to be back working on knives after about a 3 month break, after the new baby and some other stuff I just put the hobby on the back burner.

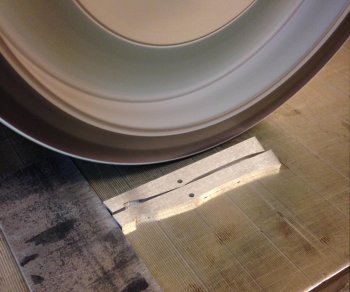

Got to do a little grinding today and it felt great, took a minute to get back into the swing of things.

I also have a edge scribe I'm building that I will share once I get it done.

So post up!

Justin

Just post up anything you might be working on. Hopefully we can keep it going.

I'm just excited to be back working on knives after about a 3 month break, after the new baby and some other stuff I just put the hobby on the back burner.

Got to do a little grinding today and it felt great, took a minute to get back into the swing of things.

I also have a edge scribe I'm building that I will share once I get it done.

So post up!

Justin