opaul

Well-Known Member

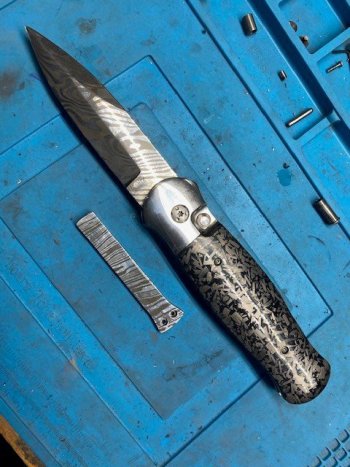

Do you think you get a better etch than using FC? I've never tried coffee but those etches look awesome.I use the exact same bottle of coffee. I’ll mix about 1/2 of it in a quart canning jar with hot water. Once done etching, I store it in the refrigerator. When needed again, I just heat it back up in the microwave. I’ve had it last more than a year that way.