Well, I'm not a hand finisher...but here's what I would do.

Don't over finish before HT. 220 tops. Get any heavy scratches off the spine and curves for sure. I see you're using 1084. That's to your favor. You can get by with minimal time in the (forge or oven?). Once you have quenched and tempered, throw that dude in white vinegar for about 8 hours. If you take it out and all the black oxide scale wipes off, you're done. If not, put it back in. Then you can start back sanding at 120, and

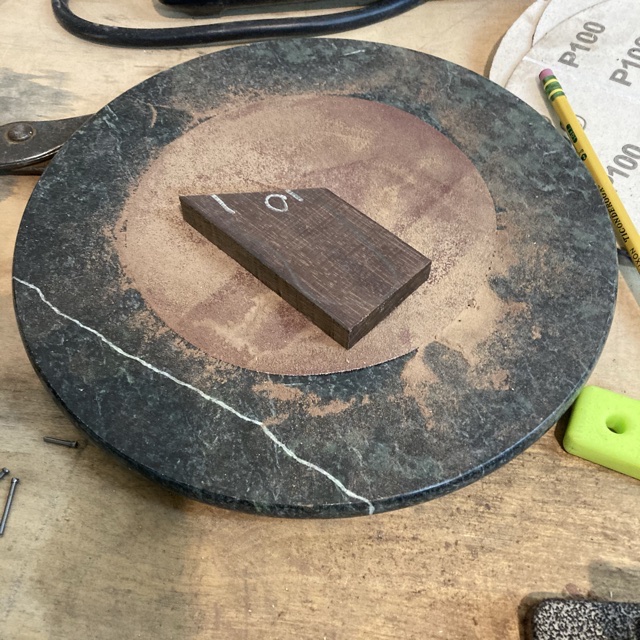

quickly moves up to 220. Most of the sanding happens at 120 and 220. This is where you get your crisp lines and flats worked out. Sand at angles so your deep scratches show and get them out before you move up in grit. 400 grit properly done, leaves a pretty nice finish. A fine or very fine scrotchbrite pad applied on a sanding backer just like paper leaves a top notch satin finish. The scotchbrite isn't nearly so bad with j-hooking as paper either.