Working on a new project! Customer wanted something where the handle and sheath matched and looks like one piece. Using magnets to hold the blade in too is another first for me!

Magnacut blade, 3.5" long, hand rubbed to 600 so far. Going to do the final clean up and pointing after the sheath is done

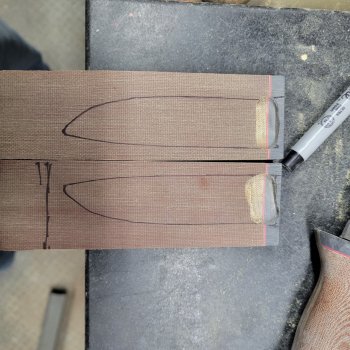

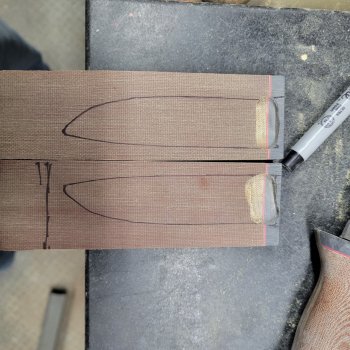

Gotta reduce the finger guard a bit still, but I started getting the sheath pieces done:

Got the spacer to fit tight to the ricasso of the blade. I left a longer ricasso so the magnets have more surface area to attract to.

And started milling the pocket to epoxy the magnets in to. One side went well, the other side, not so much! Gotta remake one of the saya scales and re mill! I am using my drill press with a machinist cross slide vise clamped to the table, but I guess I didn't have the drill press table tightened down enough!

Magnacut blade, 3.5" long, hand rubbed to 600 so far. Going to do the final clean up and pointing after the sheath is done

Gotta reduce the finger guard a bit still, but I started getting the sheath pieces done:

Got the spacer to fit tight to the ricasso of the blade. I left a longer ricasso so the magnets have more surface area to attract to.

And started milling the pocket to epoxy the magnets in to. One side went well, the other side, not so much! Gotta remake one of the saya scales and re mill! I am using my drill press with a machinist cross slide vise clamped to the table, but I guess I didn't have the drill press table tightened down enough!