Forged out a small blade in 8670, did the normalizing, thermocycling cycles before heat treating, quenched in parks AAA, tempered twice at 350 for 2 hours each time. Ground the blade out and got it sharpened for testing!

Sliced paper and whittled wood nice, good edge holding in those tests. Hit it against some mild steel with no edge damage and even shaved some mild steel from my platen, too!

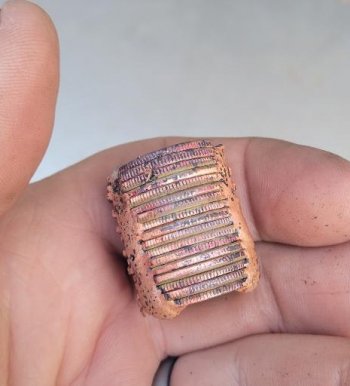

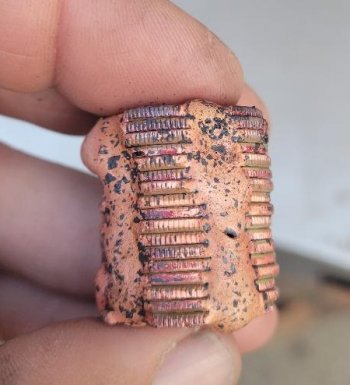

Threw it into a log and bent it out a few times and got the tip to bend slightly. Bent it back mostly straight, then hammered the blade into the log a bit over 1" deep and then hammered on the handle end with a 3# hammer several times. Flew out of the log when the tip bent a bit more. Put the blade on concrete with the handle elevated slightly and hammered it around 10-12 times with a 2.5# cross pein until it broke so I could check the grain structure. Pretty happy with the grain and performance!

Sliced paper and whittled wood nice, good edge holding in those tests. Hit it against some mild steel with no edge damage and even shaved some mild steel from my platen, too!

Threw it into a log and bent it out a few times and got the tip to bend slightly. Bent it back mostly straight, then hammered the blade into the log a bit over 1" deep and then hammered on the handle end with a 3# hammer several times. Flew out of the log when the tip bent a bit more. Put the blade on concrete with the handle elevated slightly and hammered it around 10-12 times with a 2.5# cross pein until it broke so I could check the grain structure. Pretty happy with the grain and performance!