Sean Jones

Well-Known Member

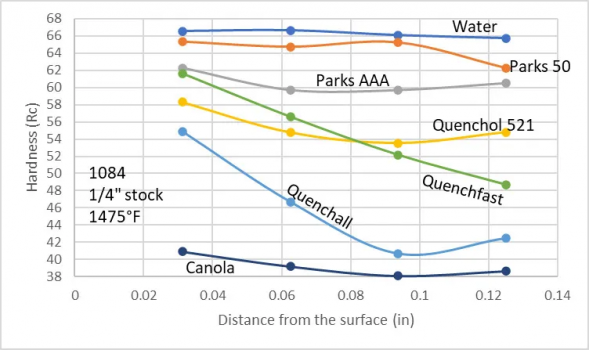

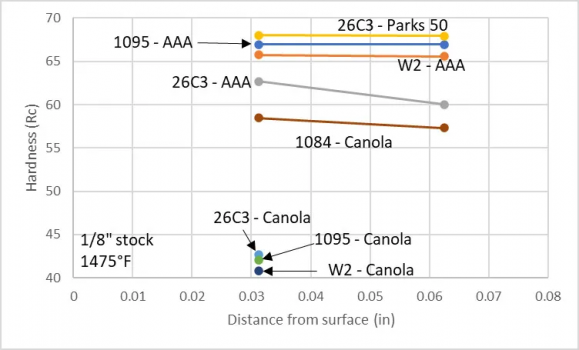

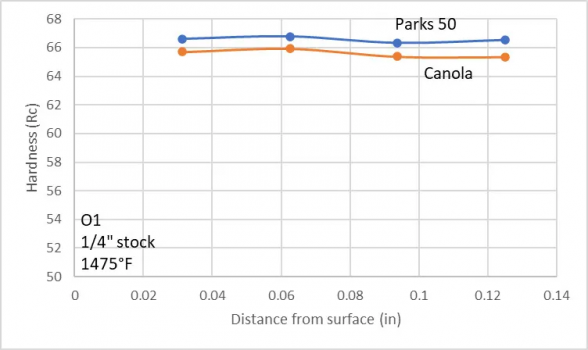

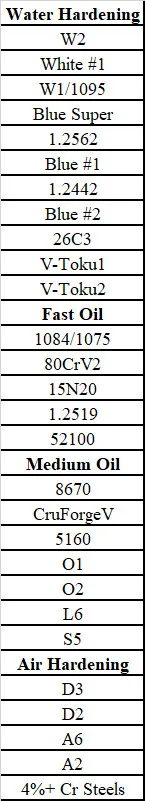

Larrin Thomas posted a YouTube video on quenching oils. His suggestion was if you are going to get only one quenching oil to make it AAA because it covers the broadest spectrum of needs. Right now I don't make very many knives so it seems to be the logical choice. I may get Parks 50 later if I find a need for it.Any reason you went with AAA instead of Parks 50? Just curious.