You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Alden Cole

Well-Known Member

Wow! That is beautiful.

Bruce McLeish

Well-Known Member

outstanding job !

REK Knives

Well-Known Member

Thanks guys

Sean Jones

Well-Known Member

Nice! Very nice!

Got some shop time in to finish off a bunch of stuff!!!

Where do I begin? 8 piece order, 5 steak knives from premade blanks with BubbleGum TJ Lam handles, chisel pry knife in 3/16" 80CRV 2, Acid etched with Halloween TJ Lam handles, 240 and 200mm chef knives in 3/32" Alabama Damascus and Halloween TJ Lam handles. Guy and his wife like colorful handles!

Also did a 3" EDC blade in Alabama Damascus and Desert Ironwood, kydex sheath.

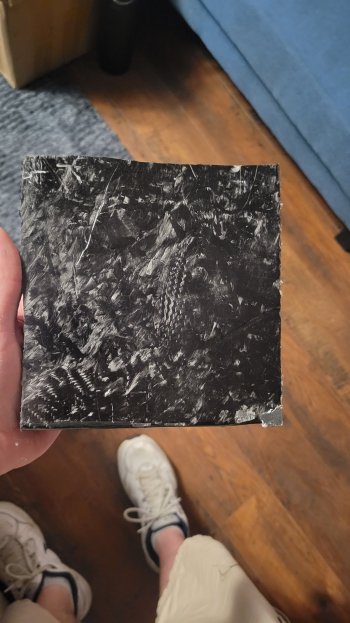

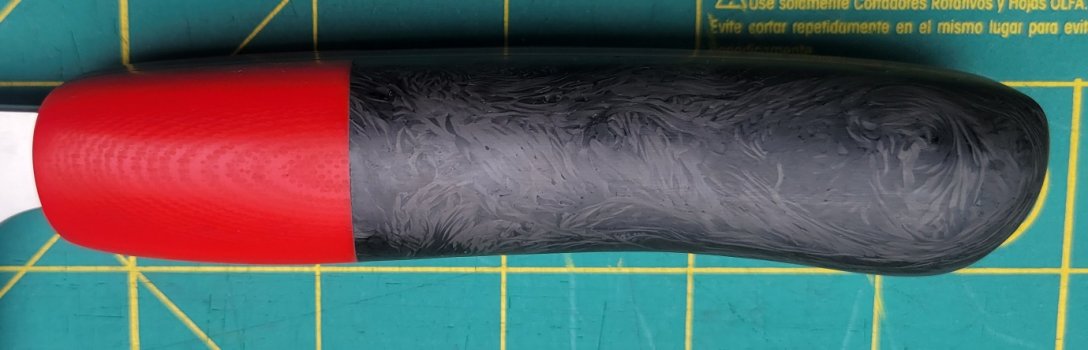

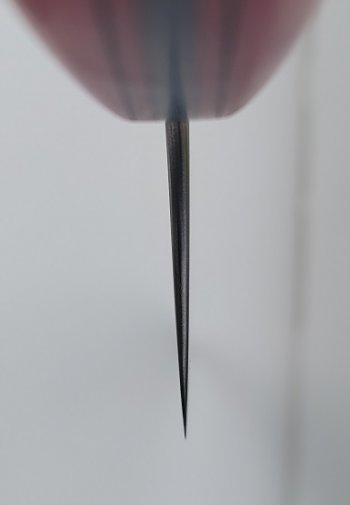

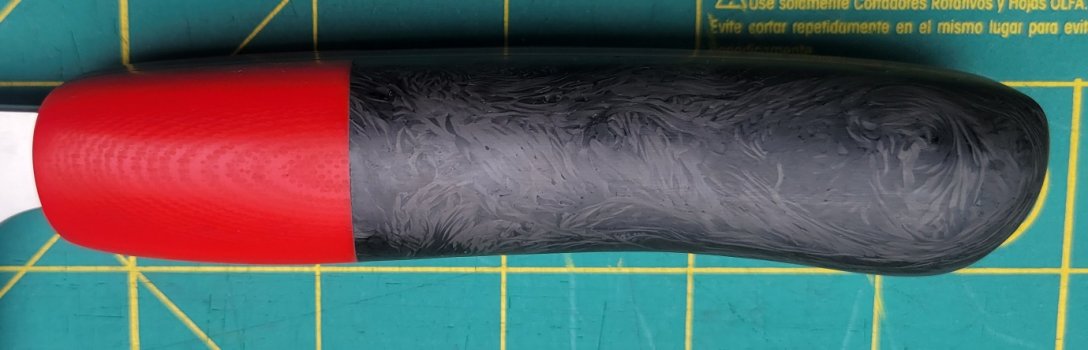

Last up is a 210mm Nitro V 3/32" blade, 62 rockwell, convex grind with red G10 bolster and liner, black G10 frame and Carbon Fiber burl that I made for the handle.

I played with 3 different firmness of felt (S2-32 from McMaster, F3 and F5 from Amazon. F3 seems to work the best for kitchen knives. The S2-32 from McMaster is very firm and I use it to help blend the full flat grind before I go to the F3 felt. It doesn't give much of a convex to the side of the blade, but works nice to blend and clean up the finish. The F3 gives a nice convex grind for a kitchen knife and I can thin behind the edge with it. The F5 is a bit soft and the area behind the edge stays thick.

One thing I played with it how the platen and belt interact. I have top of the F3 platen slightly back from the belt under tension below the top roller. This created a slight gap between the platen and belt, so when I push into that area, it gives a little more convex, but the belt is still very tight. Works very close to the Rotary Platen I used to have and worked great to thin out just behind the edge. It lets me grind and finish the whole blade on the belt and have a progressive convex grind.

Where do I begin? 8 piece order, 5 steak knives from premade blanks with BubbleGum TJ Lam handles, chisel pry knife in 3/16" 80CRV 2, Acid etched with Halloween TJ Lam handles, 240 and 200mm chef knives in 3/32" Alabama Damascus and Halloween TJ Lam handles. Guy and his wife like colorful handles!

Also did a 3" EDC blade in Alabama Damascus and Desert Ironwood, kydex sheath.

Last up is a 210mm Nitro V 3/32" blade, 62 rockwell, convex grind with red G10 bolster and liner, black G10 frame and Carbon Fiber burl that I made for the handle.

I played with 3 different firmness of felt (S2-32 from McMaster, F3 and F5 from Amazon. F3 seems to work the best for kitchen knives. The S2-32 from McMaster is very firm and I use it to help blend the full flat grind before I go to the F3 felt. It doesn't give much of a convex to the side of the blade, but works nice to blend and clean up the finish. The F3 gives a nice convex grind for a kitchen knife and I can thin behind the edge with it. The F5 is a bit soft and the area behind the edge stays thick.

One thing I played with it how the platen and belt interact. I have top of the F3 platen slightly back from the belt under tension below the top roller. This created a slight gap between the platen and belt, so when I push into that area, it gives a little more convex, but the belt is still very tight. Works very close to the Rotary Platen I used to have and worked great to thin out just behind the edge. It lets me grind and finish the whole blade on the belt and have a progressive convex grind.

the Midwest Knifemakers Guild hosted a Hammer In at USAknifemaker this weekend.

2 things to consider if you haven’t.

1. Join a knifemakers group. You make friends that actually listen when you talk about knives as opposed to your wife and normal friends.

2. Go to Hammer In’s. You will gain 1 to 2 years knowledge. I made that up but I’m not far off.

Jason Krause shows how to enhance a hamon.

Peter Martin and I made some Ti-zirc canister Damascus. 2 billets, both turned out pretty good.

Carlin A managed the forging tent and ran several people thru making their first knife shaped object.

ABS MS Howard Clark gave a heat treating demo using both water and Parks 50

Tyler Turner gave a couple sessions on making a slippy.

2 things to consider if you haven’t.

1. Join a knifemakers group. You make friends that actually listen when you talk about knives as opposed to your wife and normal friends.

2. Go to Hammer In’s. You will gain 1 to 2 years knowledge. I made that up but I’m not far off.

Jason Krause shows how to enhance a hamon.

Peter Martin and I made some Ti-zirc canister Damascus. 2 billets, both turned out pretty good.

Carlin A managed the forging tent and ran several people thru making their first knife shaped object.

ABS MS Howard Clark gave a heat treating demo using both water and Parks 50

Tyler Turner gave a couple sessions on making a slippy.

Attachments

Last edited:

REK Knives

Well-Known Member

Wow looks like a ton of fun!

Nick Riggi

Well-Known Member

Smallshop

KNIFE MAKER

...I just thought I was boring....lol.You make friends that actually listen when you talk about knives as opposed to your wife and normal friends.

Smallshop

KNIFE MAKER

Awesome OP! pics along the way?Building a new shop!

opaul

Well-Known Member

Sure! I’m hoping to start framing by this weekend.Awesome OP! pics along the way?

Gene Kimmi

KNIFE MAKER

Alden Cole

Well-Known Member

REK Knives

Well-Known Member