FD Kingery

Well-Known Member

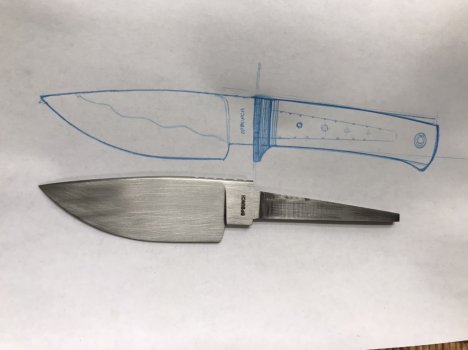

good looking knife, what is the overall length?I finished the frame handle Bowie without screwing it up too badly. Lots of fit and finish bits that could have gone better. Quite a challenge and a great learning experience. The next one will be better. On to making the sheath. There are more pics in my gallery for those interested in seeing more.

View attachment 77912