I knew going in a making dual action liner lock would be hard.

It is stupidly hard.

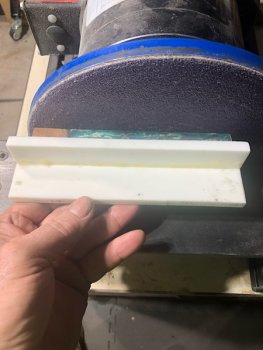

Here are some of my failures. If you learn from failure, I am closing on my Masters degree.

In fairness, each of these fails did teach me something.

View attachment 74314

I switched to Titanium liners. I just didn't like how the 410ss (not hardened) was bending. I just got in some thicker 430ss I will use (maybe) next time when I have hardened it.

I made another sear switch. Tweaked the hardened spring (which came out decent using 8670), added a stronger spring under the sear switch arm, shortened the arm and did a bunch of other stuff. If you look at the switch below, I used screws to hold the sear switch pivot in place since you can't solder Ti. Most of the day is put it together, identify an issue, fix it, reassemble, cuss, new issue, repeat.

Chuck Gedratis sent me pics of one of his for reference and positive vibes. Thanks Chuck.

He used the term "money click".

I finally heard one today.

Still lot's to do. I have to move the switch completely. I didn't leave enough room at the top to hide it under a scale. Basically, I will modify the drawing, make new pattern templates and start from scratch but I'm closing in on it.