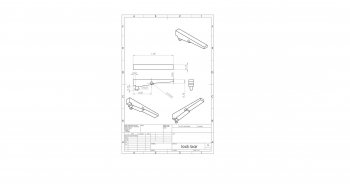

Here is a drawing of an auto knife button bar.

Machinists will hate this drawing. That's OK. I hate it too. It has a couple gaps in it that would not let your precisely machine this part. If you aren't a machinist, this will work just fine. I made this so I have a future reference for an auto knife switch bar. In reality, the actual part will vary a bit but this should give you a starting point. According to Chris Crawford, the sear pin only needs about .040" to hold the kick spring so it's length will be .040" plus what ever your liner thickness is. The sear pin is hand filed. I supposed you could press fit a dowel pin but filing only a takes a few minutes.

To keep the bar level with the scale there is a couple ways to adjust it. The front notch can be filed (it will have to rest on the liner) or depending on the length of your slot, it could rest on the end of the slot in the liner also. The bar will not be automatically level with the scale. You have to have a stop somewhere on the bar.

The sear has a notch on one side for the kick spring to rest against when energized. It also has a small slant (ramp?) to lift the button over the kick spring when closing the blade.

The length of the bar and pivot position can vary quite a bit depending on how much you want the lock bar to travel.

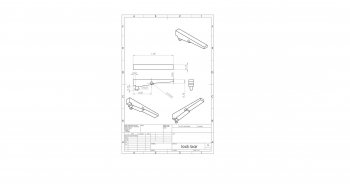

Machinists will hate this drawing. That's OK. I hate it too. It has a couple gaps in it that would not let your precisely machine this part. If you aren't a machinist, this will work just fine. I made this so I have a future reference for an auto knife switch bar. In reality, the actual part will vary a bit but this should give you a starting point. According to Chris Crawford, the sear pin only needs about .040" to hold the kick spring so it's length will be .040" plus what ever your liner thickness is. The sear pin is hand filed. I supposed you could press fit a dowel pin but filing only a takes a few minutes.

To keep the bar level with the scale there is a couple ways to adjust it. The front notch can be filed (it will have to rest on the liner) or depending on the length of your slot, it could rest on the end of the slot in the liner also. The bar will not be automatically level with the scale. You have to have a stop somewhere on the bar.

The sear has a notch on one side for the kick spring to rest against when energized. It also has a small slant (ramp?) to lift the button over the kick spring when closing the blade.

The length of the bar and pivot position can vary quite a bit depending on how much you want the lock bar to travel.