Casey Brown

Well-Known Member

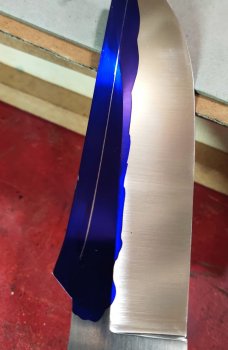

Thanks. They are the first ones I have tried doing. The bigger blades are a learning process in themselves.you’ve been busy! the bowie and gyuto blade are stunning

Thanks. They are the first ones I have tried doing. The bigger blades are a learning process in themselves.you’ve been busy! the bowie and gyuto blade are stunning

That's a lot of knives! Nice work!Decided to take a picture of the things I've been working on during this quarantine while I'm stuck in the house.

View attachment 72996

Thanks. They are the first ones I have tried doing. The bigger blades are a learning process in themselves.

Hopefully the last two of these I’ll ever make. Haha. View attachment 73047

One Of the few times I will agree with Willie Nelson!Like Willie Nelson says- before you record a song, consider having to play it every night for the rest of your life if it becomes a hit!

I used many high speed steel slitting saws. All were terrible. Rough cuts, squealing. get hot and dull etc. I bought this saw and boy howdy what a pleasant difference! Clean cuts, quiet, cool. It's the sh!t. I've cut 4ea .156 Ti frame lockbars with no change in performance. If asked they will send you a sheet of data for feeds and speeds.What kind of slitting saw would be best for Ti?

| 1/32" | 2" | 36 | 1/2" | Carbide | Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel | 3078A946 | 94.77 |

Very nice!Got a couple closer to done today!! A Gen2 Hunter in Mosaic/410 San Mai. And a big..... big..... I don't know exactly what to call it.....but I like it!

The hunter is fresh from cooling after baking on Clear Satin Moly Resin.

I talked to my Doc last week, and asked him if I could try going off one of the meds they have me on.....and ever since I've felt a bit better each day! Hope it lasts!!

Thanks Ed - what speed do you run these at?IanF: I'd recommend cut-off wheels. Personally, I use Norton A60, OBNA2. It's a 4" wheel that I put on an arbor, and use in my mill. You'll go broke quickly trying to use a slitting saw.....especially if it's not being used in a "flooded coolant" environment (like most of use DON'T have).

Thank you JesseI used many high speed steel slitting saws. All were terrible. Rough cuts, squealing. get hot and dull etc. I bought this saw and boy howdy what a pleasant difference! Clean cuts, quiet, cool. It's the sh!t. I've cut 4ea .156 Ti frame lockbars with no change in performance. If asked they will send you a sheet of data for feeds and speeds.

McMaster-Carr

1/32" 2" 36 1/2" Carbide Aluminum, Brass, Bronze, Fiberglass, Hardened Steel, Iron, Nickel, Plastic, Stainless Steel, Steel, Titanium, Tool Steel 3078A946 94.77

I'll post a picture of the feeds and speeds tomorrow. They are faster by at least 50%.Thank you Jesse

I’ve been using An abrasive wheel and thought a slitting saw may be better. Ed has advised probably not but I’m still interested and it sounds as though you’ve found a successful option. I’m not sure I’d be able to get these in Australia. Do you run yours fast or very slow? I’ve seen conflicting reports for Ti and lockbar cutting.

Ahhh, Very Clever, Can I steel your design???Now we are talking, those look good John! And that is a heck of a batch going out some nice profiles.

Here is my homemade scribe. It's not pretty and I still need to lap the face of it on my granite block to get it perfectly flat but it works an I have a total of $4.97 into it(bought a carbide edge pen scribe used the tip)