You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Bruce McLeish

Well-Known Member

THAT'S not a knife ..... (Crocodile Dundee ) !

J. Keeton

Active Member

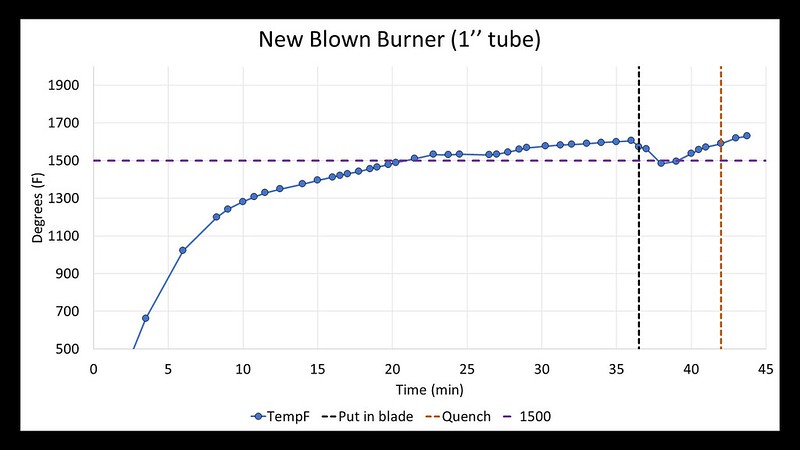

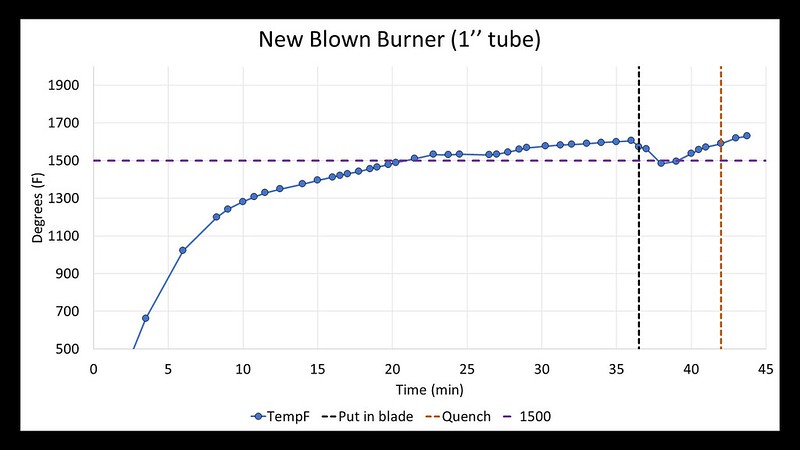

Made a new burner yesterday in an effort to run the forge at lower temps! Looks like it worked. Check out this graph:

Naturally... Because it's fun for me to do! I made a video on the build if anyone is looking to build a forced air burner for the first time:

Not saying this design is superior or anything... Just sharing what I did. Probably could have been done with way less brass!

Cheers,

JK

Naturally... Because it's fun for me to do! I made a video on the build if anyone is looking to build a forced air burner for the first time:

Not saying this design is superior or anything... Just sharing what I did. Probably could have been done with way less brass!

Cheers,

JK

John Wilson

Well-Known Member

After a longer than anticipated hiatus from the shop I’m finally back at it. I did get some great feedback from a customer while I was away. He bought several kitchen knives, one being a fillet knife. He wrote me a very nice letter and sent photos, which I am very proud to share.

“And we had a group of us go out Sunday and everyone cleans their own fish and your knife was miles better than anything everyone brought!!!! Everyone had to use it once because my brother and I were so much faster and cleaner! Amazing job! Thank you so much again!”

“And we had a group of us go out Sunday and everyone cleans their own fish and your knife was miles better than anything everyone brought!!!! Everyone had to use it once because my brother and I were so much faster and cleaner! Amazing job! Thank you so much again!”

Attachments

Bruce McLeish

Well-Known Member

Was wondering where you been. I figgered you was with that Zito feller. Nice accolade , btw.After a longer than anticipated hiatus from the shop I’m finally back at it. I did get some great feedback from a customer while I was away. He bought several kitchen knives, one being a fillet knife. He wrote me a very nice letter and sent photos, which I am very proud to share.

“And we had a group of us go out Sunday and everyone cleans their own fish and your knife was miles better than anything everyone brought!!!! Everyone had to use it once because my brother and I were so much faster and cleaner! Amazing job! Thank you so much again!”

John Wilson

Well-Known Member

Was wondering where you been. I figgered you was with that Zito feller. Nice accolade , btw.

Ha! Zito is out chasing alligators, or whatever they do over there!

Sean Jones

Well-Known Member

Nice! Very nice!

John Wilson

Well-Known Member

Sean Jones

Well-Known Member

I got an amazing deal on a Chicago Electric welder. $30.00 including half a roll of flux core wire. So I'm in business to start welding now. Tried it for the first time this weekend. Absolutely crappy work, so I'm not showing my welds but I'm learning!

Now I can continue working on my new forge.

I'm also now totally and completely out of room in my small shop! I have to move my bicycle, a wheel chair and my red cart to work.

Wife says I can't take over the other half of the garage...so I guess I'm stuck with what I've got.

Now I can continue working on my new forge.

I'm also now totally and completely out of room in my small shop! I have to move my bicycle, a wheel chair and my red cart to work.

Wife says I can't take over the other half of the garage...so I guess I'm stuck with what I've got.

Last edited:

Daniel Macina

Well-Known Member

Stang Bladeworks

KNIFE MAKER

A year ago we moved to a different house. I took a week off to redo one of the garage stalls into a small hobby shop. It's not a knife shop. It's for engraving practice, reloading (not set up yet - shotgun shells for trap and sporting clays) and rigging up the perfect tackle for slaying fish and the occasional "shop" stuff around the house.

The previous owner had a small wood shop in this stall and it was beat. It took a couple days to mud and sand, then painted the ceiling, walls and put epoxy down on the floor. The floor came out amazing. I ripped out the built in work benches, shelves and wall racks and converted everything to roll around chests or cabinets. I also added base molding all around with new wood trim around the doors and window. I changed out the lights to 4' LED and it's brighter than daylight inside. Now I obsess over the smallest bit of dust or dirt which probably isn't good but dang it's clean.

The previous owner had a small wood shop in this stall and it was beat. It took a couple days to mud and sand, then painted the ceiling, walls and put epoxy down on the floor. The floor came out amazing. I ripped out the built in work benches, shelves and wall racks and converted everything to roll around chests or cabinets. I also added base molding all around with new wood trim around the doors and window. I changed out the lights to 4' LED and it's brighter than daylight inside. Now I obsess over the smallest bit of dust or dirt which probably isn't good but dang it's clean.

Attachments

Dennis Morland

KNIFE MAKER

Tracey - I will take two! Dang that is clean...

Sean Jones

Well-Known Member

That's nice Tracy!

Bruce McLeish

Well-Known Member

Sean Jones

Well-Known Member

I like the batch idea also. Though my recent batch of five turned into two...maybe three. Hope to have those heat treated this weekend.

Hope to have those heat treated this weekend.