You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Morland's KITH WIP

- Thread starter Dennis Morland

- Start date

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

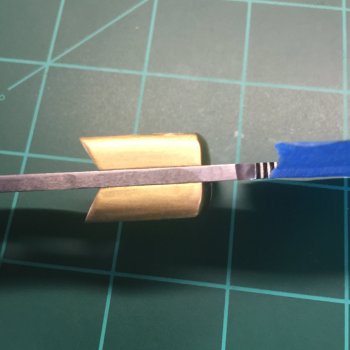

Light taps to get the pins started and the bolsters set. Once established a little bit heavier with the hammer. Maybe 3-4 taps on each pin. Flip over and 3-4 taps on each pin. Repeat as necessary.

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

I am headed to the grinder with hopes that the pins will disappear.

Dennis Morland

KNIFE MAKER

Gene Kimmi

KNIFE MAKER

Dennis,

Thanks for the step by step process. I've done wood bolsters but never metal. I will definitely be coming back to this thread when I do. Can't wait to see this one complete.

Thanks for the step by step process. I've done wood bolsters but never metal. I will definitely be coming back to this thread when I do. Can't wait to see this one complete.

Dennis Morland

KNIFE MAKER

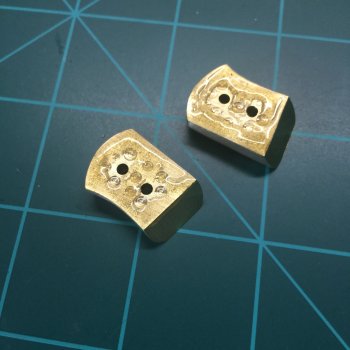

Another tip/trick that I discovered for getting a nice rounded look on the face of my bolsters. I don’t know if anyone else does this. I just started doing this for my last few knives. I think I invented it as I did not steal this idea from anyone. I use my small wheel and rotate the bolsters to get a smooth rounded look.

Attachments

Dennis Morland

KNIFE MAKER

That is pretty much how I do my bolsters. Lastly, I try to get them almost finished before attaching the handle. Brass is fairly soft. 416 ss is much harder. Both are harder than most woods. If you almost finish them, I find it easier to transition to the handle without having dips/gouges. It is just easier for me.

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

I may have to throw my solder away.

I am a horrible person to solder. It looks like a grenade hit the outhouse, every time.

Dennis Morland

KNIFE MAKER

Dennis Morland

KNIFE MAKER

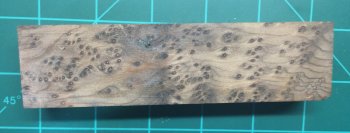

The reason I posted this that I got the redwood from John Doyle. Because it was under sized, I think I stole it. It has been in my wood stash for a couple of years. I just hit it with the belt sander to get the stabilization gunk off of it. WOW!! Thanks John Doyle. Both sides have beautiful eyes. Even one side. Remind me to be nicer to John. He did me a solid with this piece of wood.

Attachments

Dennis Morland

KNIFE MAKER

Spent an hour or so shaping and sanding the bolsters to almost done. Time to focus on the scales.

Attachments

-

AAF9683B-8F65-455D-BBE9-26207010B21F.jpeg571.5 KB · Views: 9

AAF9683B-8F65-455D-BBE9-26207010B21F.jpeg571.5 KB · Views: 9 -

EF008396-A5EB-4C4B-A9AE-79F3702AB645.jpeg558.2 KB · Views: 10

EF008396-A5EB-4C4B-A9AE-79F3702AB645.jpeg558.2 KB · Views: 10 -

34B26E44-2466-4A23-BE29-5937F59B9795.jpeg586.7 KB · Views: 9

34B26E44-2466-4A23-BE29-5937F59B9795.jpeg586.7 KB · Views: 9 -

E30491F3-22F8-4149-981E-8670E5B94818.jpeg672 KB · Views: 11

E30491F3-22F8-4149-981E-8670E5B94818.jpeg672 KB · Views: 11 -

F2806195-CB84-4B35-9320-DEF96DCFEFDE.jpeg675.9 KB · Views: 10

F2806195-CB84-4B35-9320-DEF96DCFEFDE.jpeg675.9 KB · Views: 10 -

8CD8BAE6-BF81-4722-847A-969776B3B94E.jpeg683.5 KB · Views: 10

8CD8BAE6-BF81-4722-847A-969776B3B94E.jpeg683.5 KB · Views: 10