Daniel Rohde

Well-Known Member

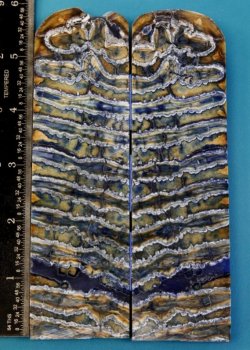

I will be making a Ed Fowler style handle: I will take some picture along the way and post. I will also be making a some of the horn into scales make a full tang knife with it.those materials are going to look awesome on a knife. I'm a huge fan of any kind of Koa. How do you go about using the sheep horn? (newb question)

http://customknifegallery.com/fowler_ut1_500.jpg

Last edited: