Mark Redmon

Well-Known Member

Looks good Matt! I've updated the list.

Here's what I came up with:

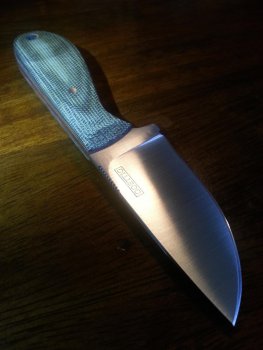

Steel: CPM D2

Scales: Burgandy Linen Micarta

Hardware: C110 Copper bolsters and pins, brass mosaic pin and thong hole liner

Bade: Just shy of 4" from tip to front of bolsters

This is far from perfect... The big standouts are that my makers mark came out bad on this one, and the bolsters are off just a hair. This is only my second knife with copper bolsters, and I suspect that the softness of the pins allowed a bit more movement when peining the bolsters. At any rate, I feel it's a solid and comfortable knife, and I hope whoever receives it gets good use out of it.

Thanks, Derek! I have mixed feelings about the copper... I like the look of it, but it gets HOT fast when grinding. Of course, it's pretty soft, and will scratch if you look at it funny. I'm sure I'll use it again soon on another project.That came out really really nice. I love the copper!