Ryan Minchew

Well-Known Member

Me too Sean!I'm far enough along to need bushings...which of course I forgot to order since they'll have to come from another source.

Wouldn't it be nice to be able to buy everything we need at competitive prices from one place?

Anyway, I'll have bushings soon.

I did start on my rise/fall indicator. Have you ever tried drawing a circle with an Etch-a-Sketch? That's what it's like for me trying to mill a circle for the dial indicator to set in.I never could draw worth a dang.

What and no pictures of the rise and fall indicator ban1

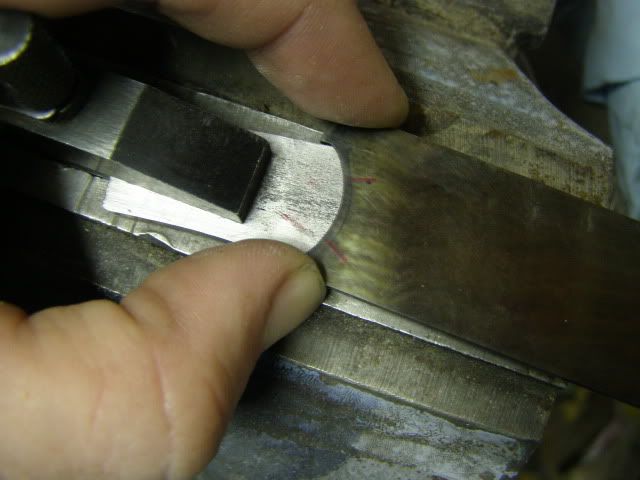

Well I got some more fuses yesterday afternoon. I've etched the relief on both of the black lip knives and started on the others that I've been working on. I may have a couple of these done for the show to recoup the cost of that blacklip i may or may not have broke......