You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

Sean Jones

Well-Known Member

That's the only thing I can think of. It's worked fine before. I got a little bit careless (and irked) taking things off when I realized I had buggered up my logo. I could have easily done that.Know what caused it or else you may destroy/fry something . Possibly arced the leads?

Daniel Macina

Well-Known Member

Guess who spilled an entire bottle of red leather dye on the table tonight? Looks like I will be refinishing a table

Sean Jones

Well-Known Member

Ouch! My wife is after me to refinish our kitchen table. That's probably what it will take.Guess who spilled an entire bottle of red leather dye on the table tonight? Looks like I will be refinishing a table

Daniel Macina

Well-Known Member

Thank God it was at the house we no longer stay at and the table was in bad shape anyways. Only reason I was doing that sort of work on it.

Daniel Macina

Well-Known Member

chrisstaniar

Well-Known Member

Guess who spilled an entire bottle of red leather dye on the table tonight? Looks like I will be refinishing a table

I forget which leather company tutorial I was watching but he had obviously spilled before and recommended putting the dye jar in an old pickle jar so it would be harder to spill.

John Wilson

Well-Known Member

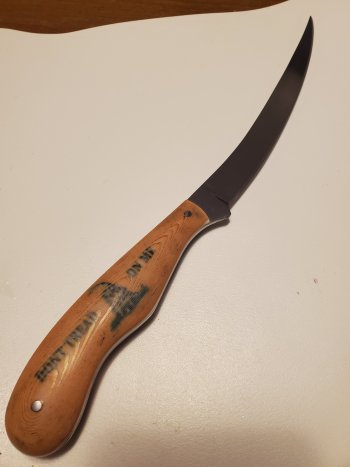

A repeat customer of mine who has become a friend approached me a couple of months ago. He wanted to give his son a Christmas present of making his own knife and asked if I’d be willing to do that. My answer was ABSOLUTELY!! I’ve known his son for about six years. He was a kid starting high school when I met him and now he’s in college. He’s a terrific young man.

His son has been coming over to the shop where he works on each stage of his knife per visit. It has been a blast watching this young man learn and seeing his nervousness turn into pride as his knife takes shape in his hands.

We did the heat treat yesterday evening. Here’s a picture of him holding it before it went into heat treat.

His son has been coming over to the shop where he works on each stage of his knife per visit. It has been a blast watching this young man learn and seeing his nervousness turn into pride as his knife takes shape in his hands.

We did the heat treat yesterday evening. Here’s a picture of him holding it before it went into heat treat.

Attachments

Bruce McLeish

Well-Known Member

Geez John. I may have to rethink all of the things I've said about you....well, most of them anyway!

Good job with the youngin.

Good job with the youngin.

Randy Lucius

Well-Known Member

That's awesome John! Must be a great feeling to be able to pass on the joy of knifemaking to another. Well done.A repeat customer of mine who has become a friend approached me a couple of months ago. He wanted to give his son a Christmas present of making his own knife and asked if I’d be willing to do that. My answer was ABSOLUTELY!! I’ve known his son for about six years. He was a kid starting high school when I met him and now he’s in college. He’s a terrific young man.

His son has been coming over to the shop where he works on each stage of his knife per visit. It has been a blast watching this young man learn and seeing his nervousness turn into pride as his knife takes shape in his hands.

We did the heat treat yesterday evening. Here’s a picture of him holding it before it went into heat treat.

chrisstaniar

Well-Known Member

Drop Point for a client - aebl, stainless bolsters, black/brass accents, stabilized maple burl scales with mosaic pins.

Tried to talk the client into solid pins but they wanted bling. This is also the first time I tried out my "fold up photo box" and it worked great. Basically folds up like a car sunscreen and then when you want to use it, it just pops open. Cost me about $25 on Amazon, came with 3 colors of backgrounds. It was nice not having the glare from a light. That glare always seems to be pointing right at the camera.

Tried to talk the client into solid pins but they wanted bling. This is also the first time I tried out my "fold up photo box" and it worked great. Basically folds up like a car sunscreen and then when you want to use it, it just pops open. Cost me about $25 on Amazon, came with 3 colors of backgrounds. It was nice not having the glare from a light. That glare always seems to be pointing right at the camera.

Gliden07

Well-Known Member

Just finished this one up for a customer. Another with 2 different scales. This has been what I consider a strange request. But I get paid for both sets of them. Just don't know what to do with the extra scales though!! Hopefully they'll order another knife!

Attachments

Randy Lucius

Well-Known Member

That is a strange request but considering both are of a patriotic theme I guess I understand. Hope he buys another one.Just finished this one up for a customer. Another with 2 different scales. This has been what I consider a strange request. But I get paid for both sets of them. Just don't know what to do with the extra scales though!! Hopefully they'll order another knife!

Randy Lucius

Well-Known Member

Not bad at all for a first grind. I still have trouble sometimes with my weak hand. What kind of grinder are you using?

Gliden07

Well-Known Member

I think they are doing Alec Steeles 2x72 and Surface grinder attachment.It’s a 2x48 by an Australian company called 84 Engineering.

1Zach1

Active Member

Yeah I got it through Alec Steele Co. Wish I could afford the SGA, even though I don't have any need for it right now. Gear addiction is a thing. But I can quit anytime, I swear!I think they are doing Alec Steeles 2x72 and Surface grinder attachment.

My buddies Peter Martin and Jess Hoffman are coming over Friday to play in the shop.

Peter and I like to see what goofy stuff we can do while Jess supervises.

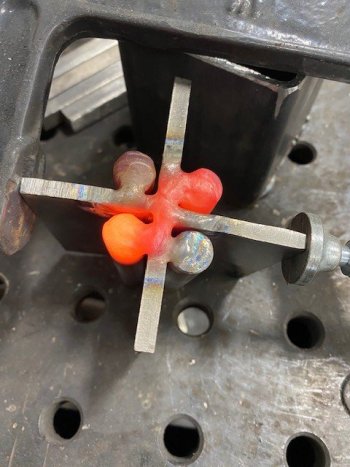

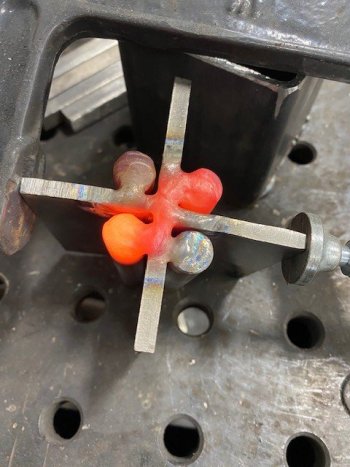

We decided to attempt to make a Titanium canister. We found some powdered Ti on amazon and hopefully we can pull this off. This the start of my can. Filling a 3x3x3" can with Ti is stupidly expensive - and especially for an experiment that we can't find any others to copy from.

I have done a couple cans of Ti previously but never with powder. We will see how it goes.

Naturally, there has to be a blood sacrifice.

After some thought I came up with this. Using a TIG welder I joined these pieces on the top and bottom just to hold them in place.

The Tig is hot.

ready for powder and weld it shut.

We know that Ti turns really soft inside a can around 1900F. Like jelly soft. I have had it squirt out in the past when I've done this.

Our plan to get the can to temp is to soak it in an oven at 1800F for an hour. After that we will squeeze with squaring dies in the press and then move the billet over to the forge to stretch it out. We are going after bolster material about 1.5" square.

We are also going to try to lay up some copper san-mai billets.

Neither of us has used Ti powder in a can before. Hopefully we can get it to weld up.

Wish us luck.

If you are in the neighborhood Friday afternoon, stop by the shop.

Peter and I like to see what goofy stuff we can do while Jess supervises.

We decided to attempt to make a Titanium canister. We found some powdered Ti on amazon and hopefully we can pull this off. This the start of my can. Filling a 3x3x3" can with Ti is stupidly expensive - and especially for an experiment that we can't find any others to copy from.

I have done a couple cans of Ti previously but never with powder. We will see how it goes.

Naturally, there has to be a blood sacrifice.

After some thought I came up with this. Using a TIG welder I joined these pieces on the top and bottom just to hold them in place.

The Tig is hot.

ready for powder and weld it shut.

We know that Ti turns really soft inside a can around 1900F. Like jelly soft. I have had it squirt out in the past when I've done this.

Our plan to get the can to temp is to soak it in an oven at 1800F for an hour. After that we will squeeze with squaring dies in the press and then move the billet over to the forge to stretch it out. We are going after bolster material about 1.5" square.

We are also going to try to lay up some copper san-mai billets.

Neither of us has used Ti powder in a can before. Hopefully we can get it to weld up.

Wish us luck.

If you are in the neighborhood Friday afternoon, stop by the shop.

Last edited: