Daniel Rohde

Well-Known Member

Thanks!Daniel, it's a belt run surface grinder. It takes the same belts as my 2 x 72.

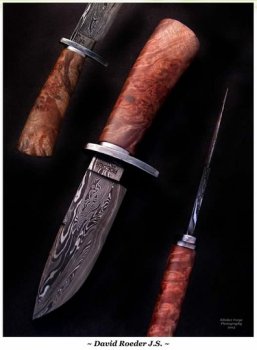

The Christmas project is something I've been doing for a few years now. It started as just a one time idea but quickly turned into an annual event. I make a knife of my choosing and sell it. It's always one of my higher end pieces, whether it's a hunter, bowie or folder. 100% of the proceeds I give anonymously to a random local struggling family (usually with kids) right before Christmas.

I can't hardly stand the idea of a nice family with kids not having a bright Christmas. The Christmas knife project is probably the highlight of my year, every year.

That's a really cool thing you do, thanks for sharing! So is that going to be the bigger blade up above? that's a good way to end and start the year.