Cleaned the top of the column and bottom of the anvil where I found some grease and adjusted the dashpot ao the weights fall in 4-5 seconds instead of the 3.5 when there was no test sample. Now it tests on or 1 point low, but the low readings are consistent and on a test block that the previous owner tested on both sides.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

ashwinearl

Member

Another Gunstock from pattern I adapted from others online, specifically an Ohta. If anyone wants the drawing in PDF or in SVG format (drawn initially in inkscape) let me know.

CPM-154, Vintage Micarta scales, SS bolsters, liners, shield, pin, Bronze washers. 3 5/8" closed

If you are interested in end-to-end build along with over a hundred pictures/descriptions on process, I did one Build alonghere at Reddit as an experiment. My intention is to redo it into forum format and then into pdf.

Instagram video of walk/talk here:

CPM-154, Vintage Micarta scales, SS bolsters, liners, shield, pin, Bronze washers. 3 5/8" closed

If you are interested in end-to-end build along with over a hundred pictures/descriptions on process, I did one Build alonghere at Reddit as an experiment. My intention is to redo it into forum format and then into pdf.

Instagram video of walk/talk here:

opaul

Well-Known Member

Especially like the bottom blade.Did some more tuning on the hrc tester. The dial lever needed adjustment and now its pretty much dead on to the 63.6 test block and several blades from Bos HT.

Shortened the handle on the S90V blade and did the sheaths for that one, the burlap handle one and the 80crv2 blade.

View attachment 83899View attachment 83900View attachment 83901

Played around with the finish on the Magnacut gyuto. I had read about doing a faux kasumi finish with 220 grit SIC sandpaper on a foam or leather backer whileo using 220 grit SIC powder mixed with mineral oil on the blade and tried it on some differentially heat treated blades. It gives a contrast between the harder steel and softer steel and gives a more matte finish and a kasumi like finish without having to use the softer Japanese finger stones. I had tried it before using leather on a hard backer, the sandpaper and 220 grit SIC powder and always seemed to have deep gouges left behind.

I got some craft foam (thin stuff like 2mm and some thicker 5mm or 6mm or so stuff and put a layer on some cork and super glued some of the foam to a wide craft/popsicle stick. I had also picked up 500 SIC and 1200AO powders, too. I worked my way up from an EDM stone finish (600 grit EDM stone) and used the 500 SIC powder as I worked up 240, 320, 400, 600 sandpaper. I then went to 800, and 2000 grit paper while using the 1200 AO powder, too. It gives a nice 600 grit hand rub finish, but isn't as shiny as a 600 grit handrub normally is; it's more of a matte finish. The oil and SIC powder allows you to use a "scrubbing" back and forth motion without getting the j hooks and stuff like that and with the SIC, it's much faster on Magnacut and other harder to finish steels! The 500 grit powders seemed to work nicer than the 220 grit powders. The 1200AO doesn't do much against the hardned Magnacut.

I will see how the finish does tonight when I cook!

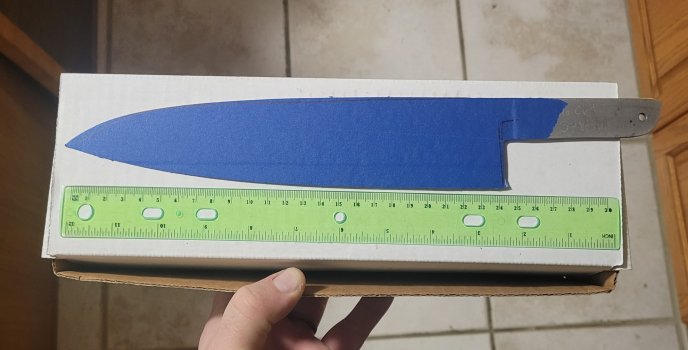

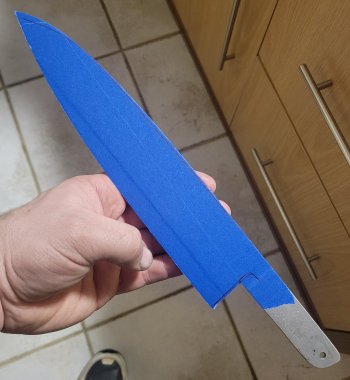

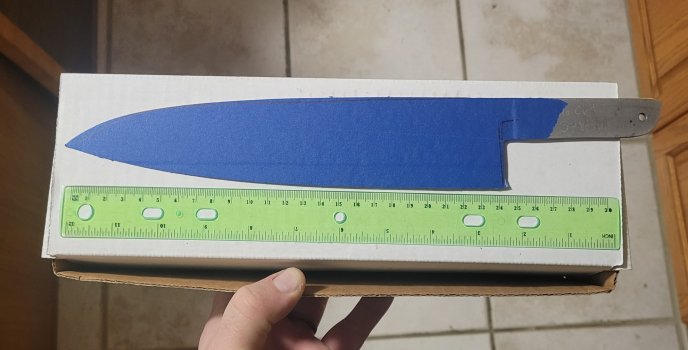

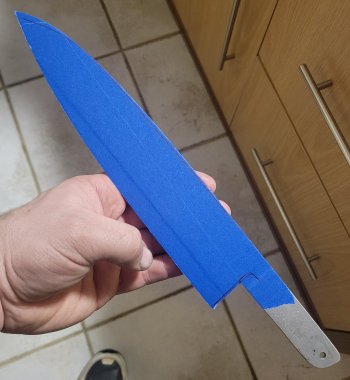

The profile looked a bit off to me, so I traced one of my Kurosaki Japanese 240mm Gyuto and found I had a hump in the spine halfway down the blade, so I will reprofile it slightly today!

I got some craft foam (thin stuff like 2mm and some thicker 5mm or 6mm or so stuff and put a layer on some cork and super glued some of the foam to a wide craft/popsicle stick. I had also picked up 500 SIC and 1200AO powders, too. I worked my way up from an EDM stone finish (600 grit EDM stone) and used the 500 SIC powder as I worked up 240, 320, 400, 600 sandpaper. I then went to 800, and 2000 grit paper while using the 1200 AO powder, too. It gives a nice 600 grit hand rub finish, but isn't as shiny as a 600 grit handrub normally is; it's more of a matte finish. The oil and SIC powder allows you to use a "scrubbing" back and forth motion without getting the j hooks and stuff like that and with the SIC, it's much faster on Magnacut and other harder to finish steels! The 500 grit powders seemed to work nicer than the 220 grit powders. The 1200AO doesn't do much against the hardned Magnacut.

I will see how the finish does tonight when I cook!

The profile looked a bit off to me, so I traced one of my Kurosaki Japanese 240mm Gyuto and found I had a hump in the spine halfway down the blade, so I will reprofile it slightly today!

Edwardshandmadeknives

Well-Known Member

I only did one knife with ram horn. Just worked it like wood basically.Unclamped. Now I’ll start working on refining the handle. Any advise from you guys on finish work with ram horn would be appropriated. Yeah / I already know it stinks.

View attachment 83967View attachment 83968

opaul

Well-Known Member

One thing I found out. Once past the rough scale part, the horn becomes translucent and the liner shows through. As in this case I have the horn mounted on green liners.I only did one knife with ram horn. Just worked it like wood basically.

Edwardshandmadeknives

Well-Known Member

Good to know!One thing I found out. Once past the rough scale part, the horn becomes translucent and the liner shows through. As in this case I have the horn mounted on green liners.

opaul

Well-Known Member

Looking good. I do like the 80CRV2 steel.Made a little fixed blade very close to the benchmade bugout! 80CRV2 steel that I heat treated to 62, OD green canvas micarta handles, black pins and black micarta lanyard tube.

View attachment 83973

Working on this one with grey/black G10 camo handle scales, white pins, black lanyard tube and a roughly 3" 80CRV2 blade:

View attachment 83974

Working on an anvil stand for a round anvil someone gave me. I think it's a pin from some heavy equipment. It itself is a beast! Whatever it is, it's one solid chunk of steel!

It seems like it has to be tool steel, but it's dinged up on both sides, so not sure how it'll go when I start using it.

.

.

Kind of a challenge building a stand for something round. The pin will set in there about 5" and the top will have a homemade flange that'll help hold the wood together and the pin.

I might make the flange out of the railroad plate laying on the table in the corner of the picture. I have thinner stuff I can wrap around the top corners, too, so not sure yet. Maybe both, now that I think about it.

The top hole might work for some type of tooling, probably not much though.

It seems like it has to be tool steel, but it's dinged up on both sides, so not sure how it'll go when I start using it.

.

.Kind of a challenge building a stand for something round. The pin will set in there about 5" and the top will have a homemade flange that'll help hold the wood together and the pin.

I might make the flange out of the railroad plate laying on the table in the corner of the picture. I have thinner stuff I can wrap around the top corners, too, so not sure yet. Maybe both, now that I think about it.

The top hole might work for some type of tooling, probably not much though.