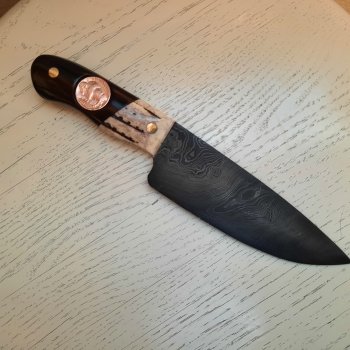

Stang Bladeworks

KNIFE MAKER

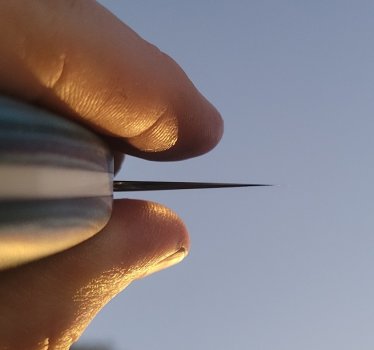

Thanks. I use a corner rad endmill. It helps for sure. I mill everything soft then heat treat.I rough mine on CNC...grind after HT. you have speeds and feeds and cutter choice very dialed to get finishes that nice!

Thanks. I use a corner rad endmill. It helps for sure. I mill everything soft then heat treat.I rough mine on CNC...grind after HT. you have speeds and feeds and cutter choice very dialed to get finishes that nice!

Nice!I hope to be moving equipment in around the first of the year.

Looking amazing! Are you gonna have storage in some type of loft/attic area? Looks tall enoughI hope to be moving equipment in around the first of the year.

I used a steep pitch for the roof but opted to go with prefab trusses so minimal storage in the ‘attic’. I went with 10’ studs on two courses of block which gives me about a 12’ ceiling. I’ll have plenty of wall space for tool storage and higher bin storage if needed. I put a shed roof off the back which will be enclosed to house a 850 gallon well fed cistern providing water for the main house.Looking amazing! Are you gonna have storage in some type of loft/attic area? Looks tall enough

Thank you!Wow, that's nice! is that being built where you live now or did you get another piece of land?

Tell us more about the design of that shop, Opaul. I see you live in North Carolina, so I'm wondering why the steep pitch on the roof. I would expect that in heavy snow areas, but not so much down your way. Having seen your knives and your posts, I'm sure a lot of thought went into the design. Love the idea of a sizable cistern for the house.I hope to be moving equipment in around the first of the year.

A vacuum pot would eliminate that. Perhaps use more epoxy and squeegee the excess from each layer as you add them, trying to eliminate air bubbles.there are lots of air holes