Josh Dabney

Moderator

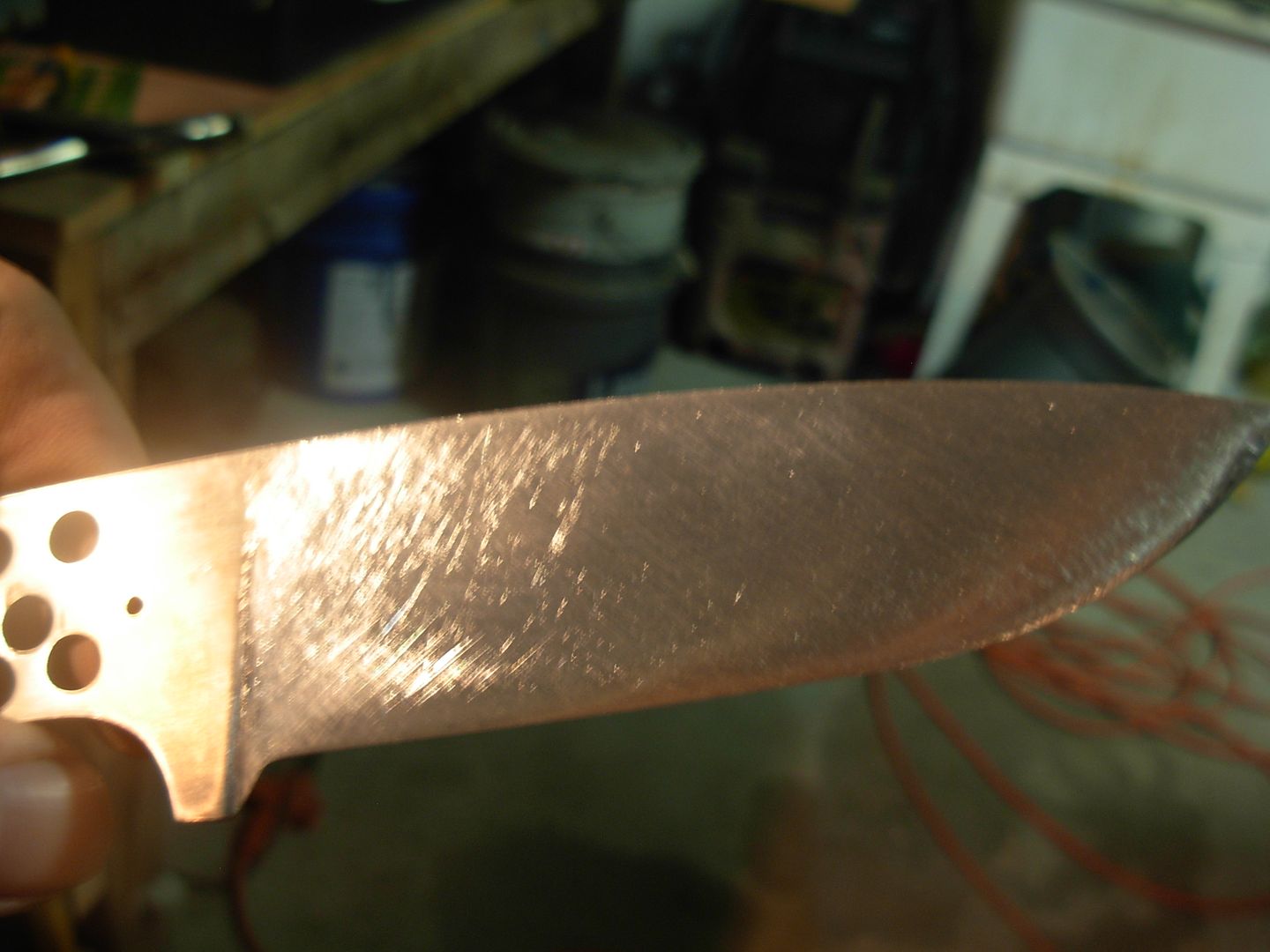

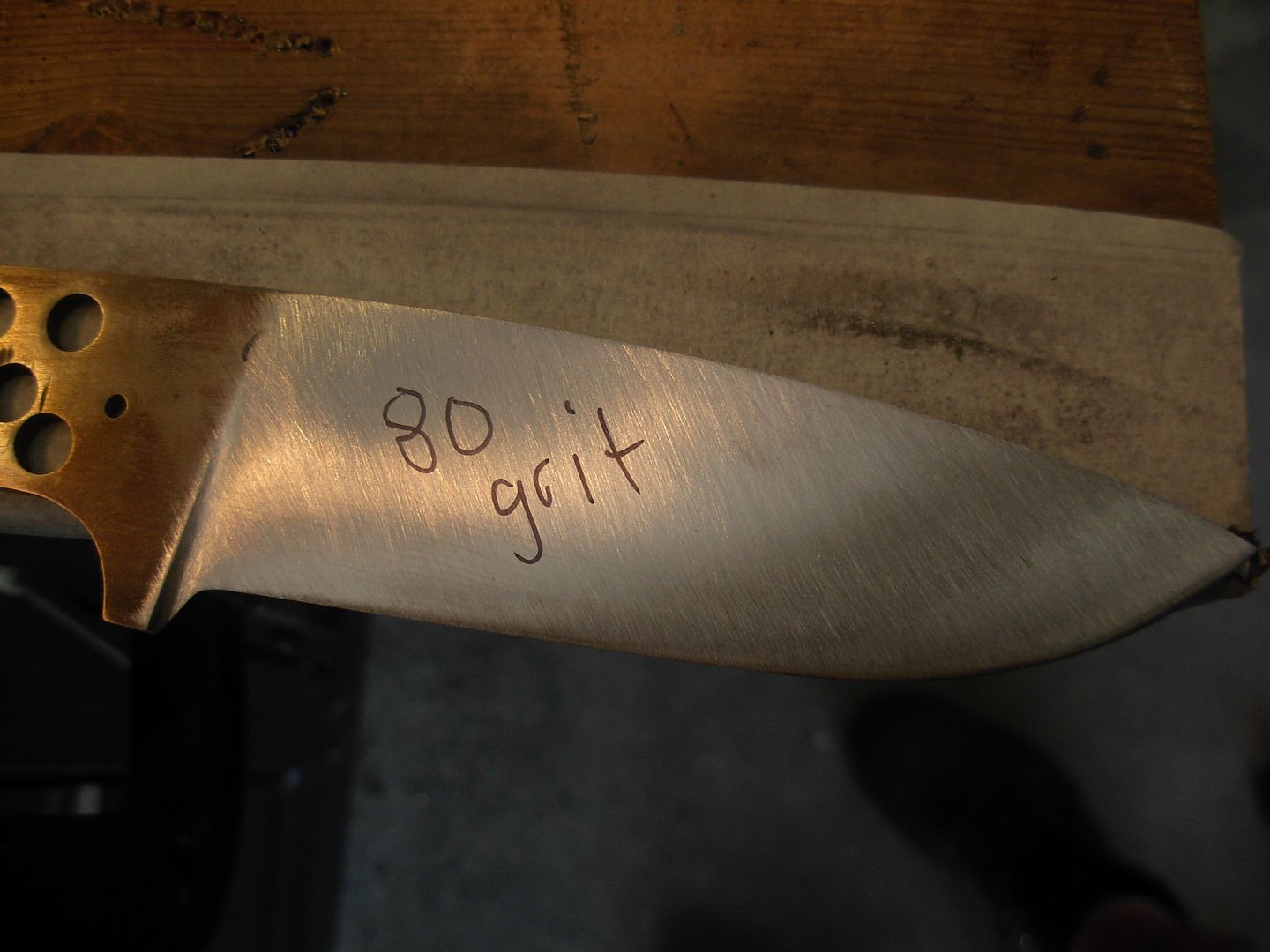

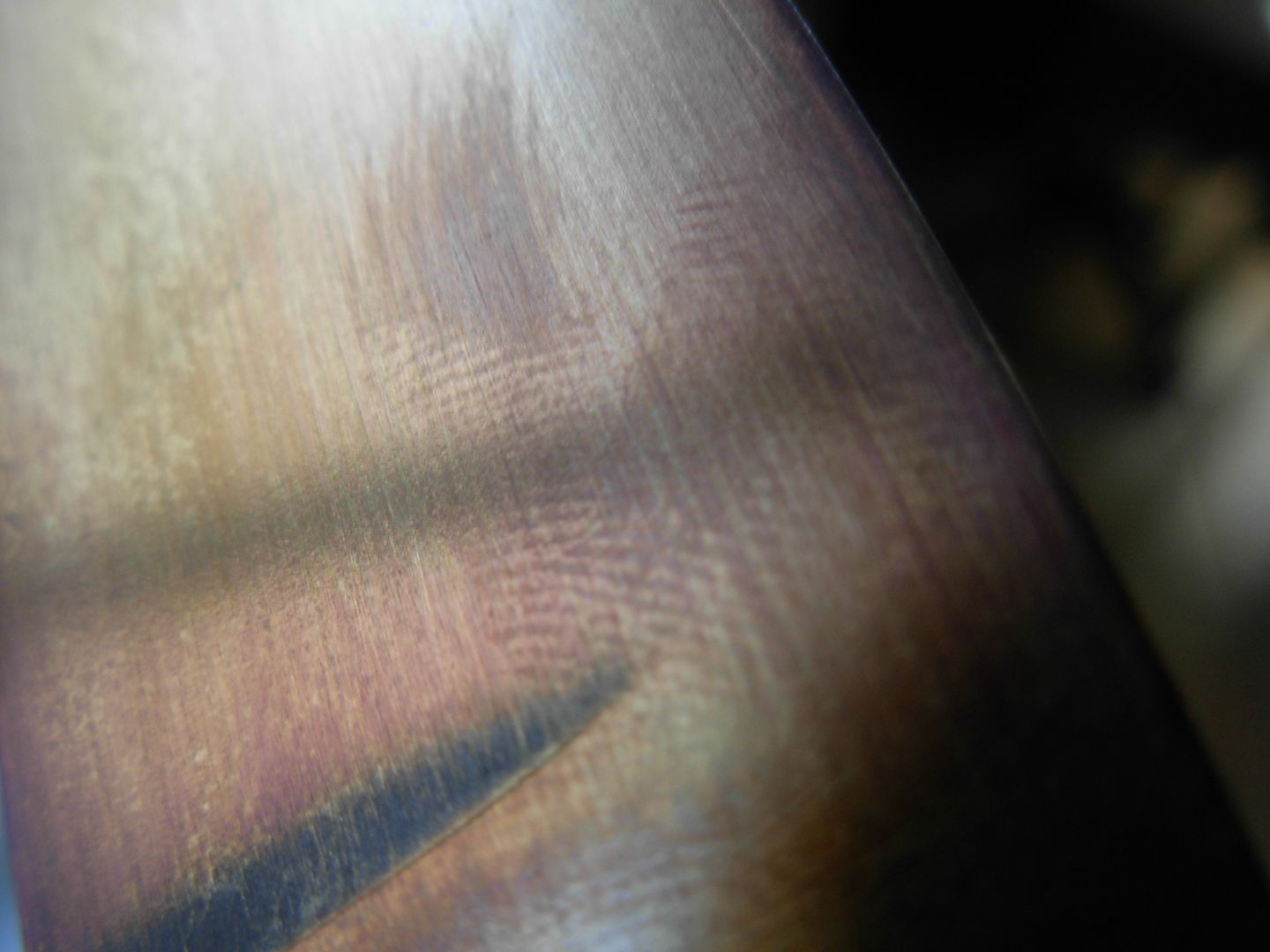

We have completed Stage 2 of our build with the second tempering cycle so let's take a look at our blade and talk a little about what we see and why we see it.

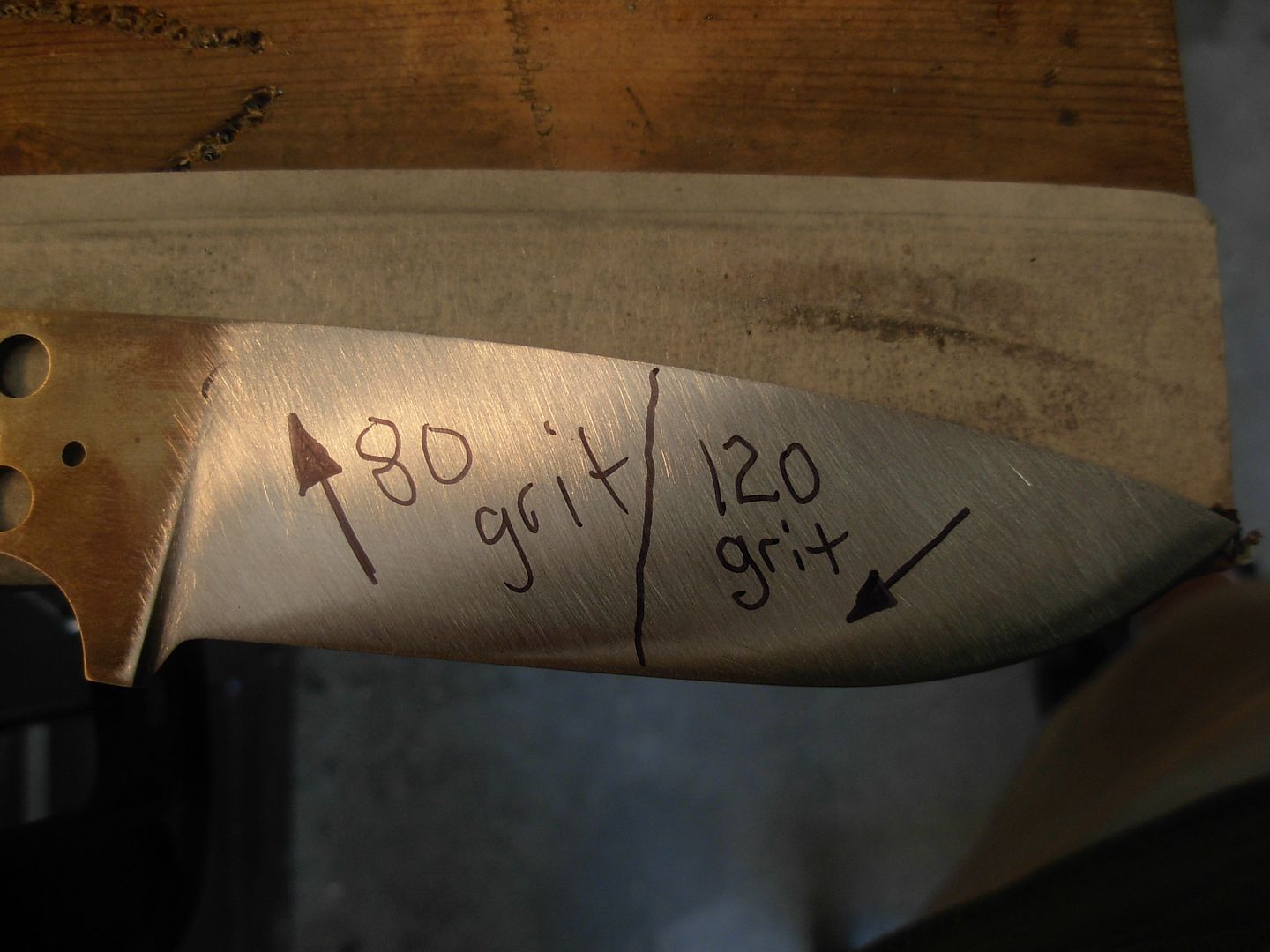

Whenever we're talking about heat and steel there are two main factors that have an effect on the steel TIME & TEMPERATURE

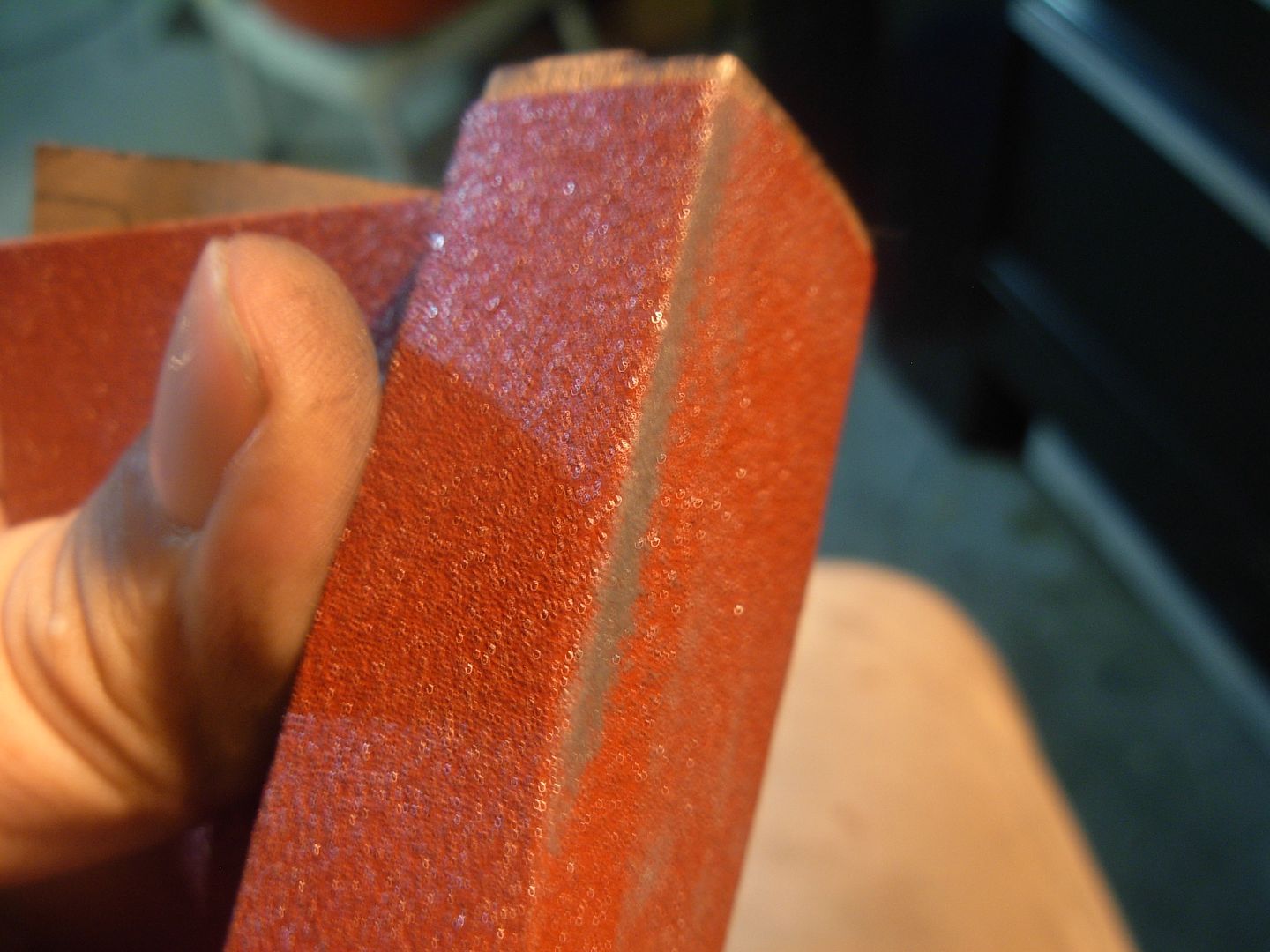

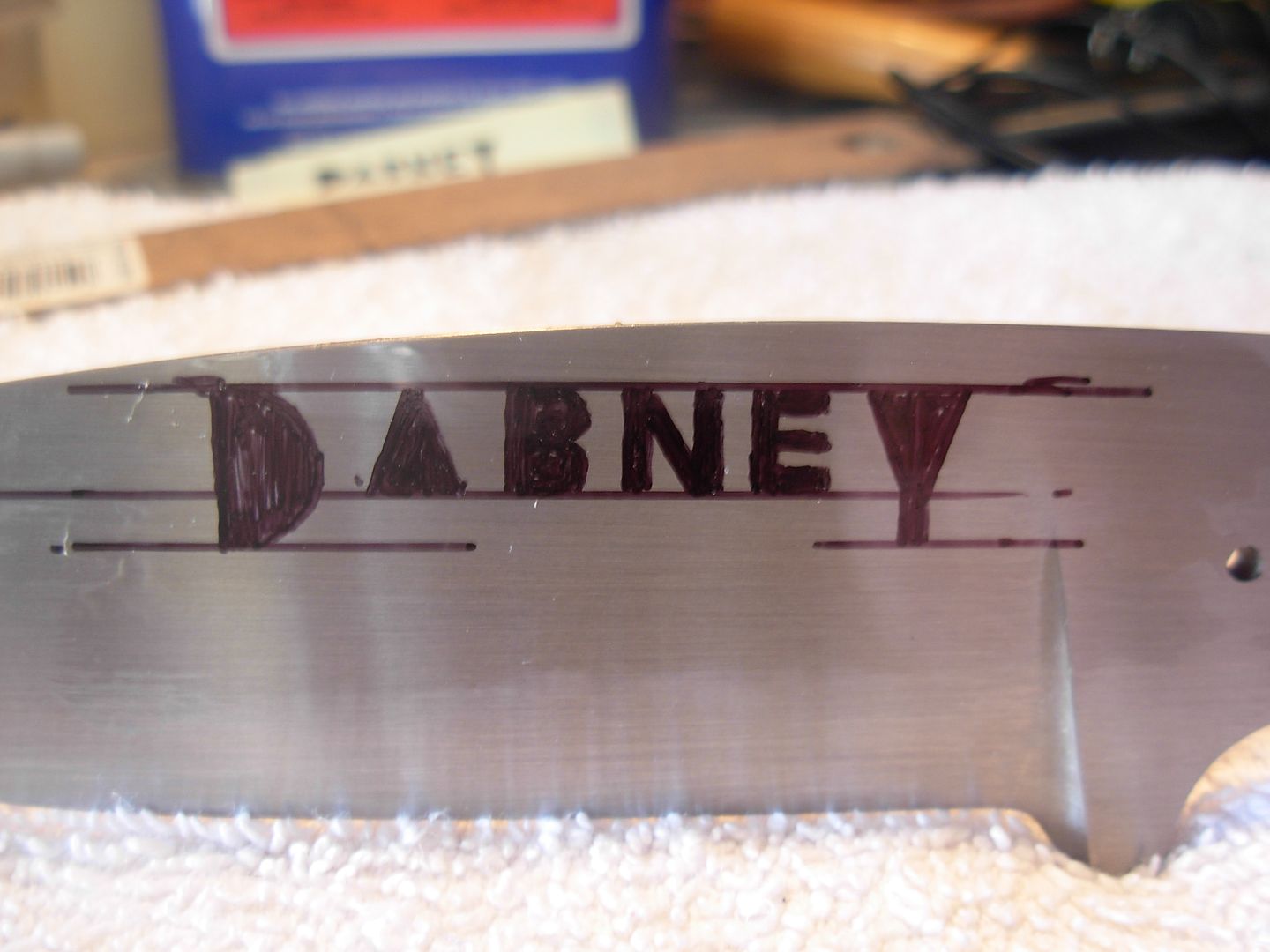

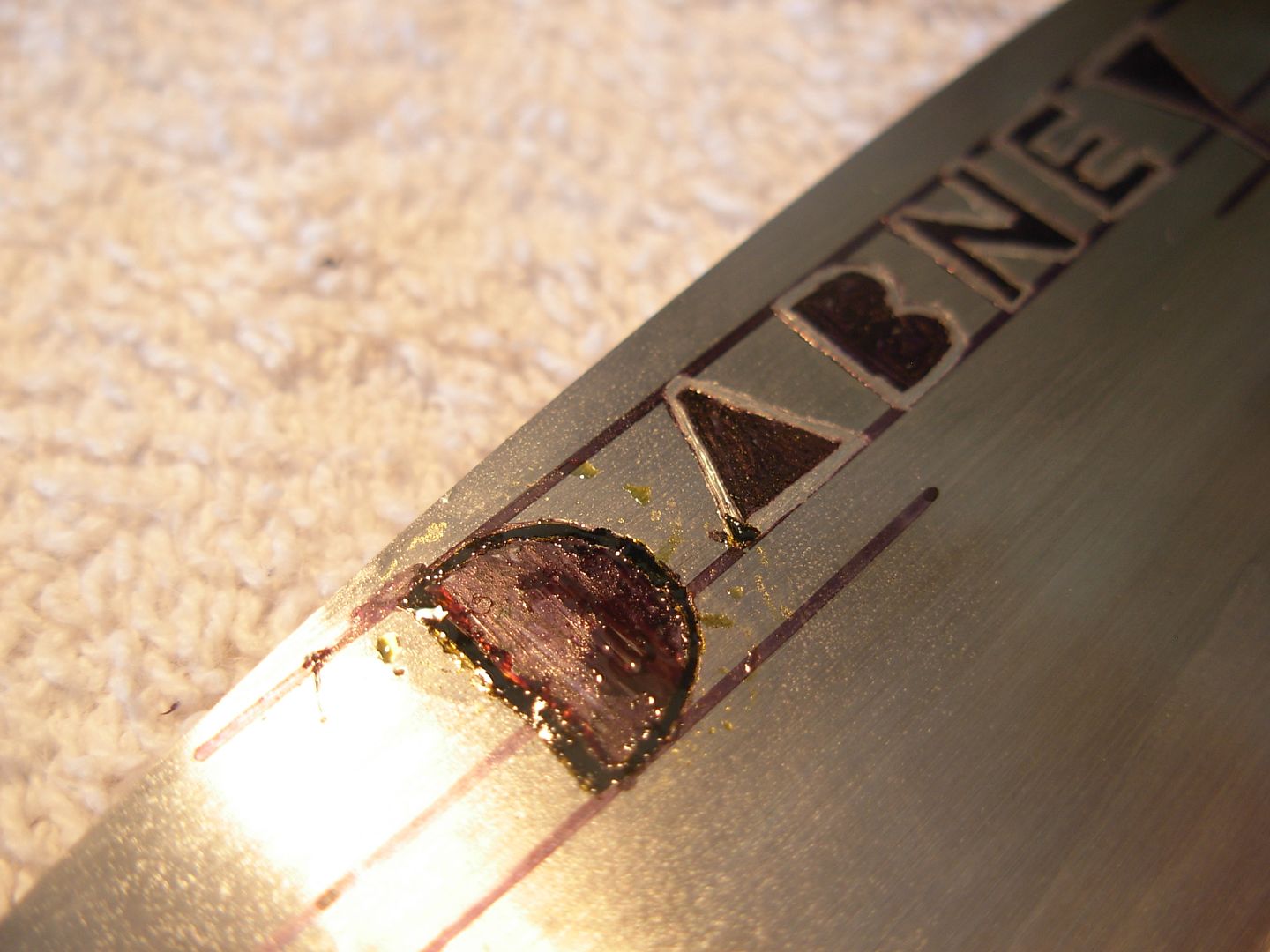

On our second tempering cycle we have not raised the temperature from our first cycle. However, our blade is going to look quite different after the second temper due to the TIME our blade has been exposed to the 400 degree heat. Because of this we're going to see a much bolder coloring of our steel which is to be expected.

Our gold coloring had deepened a little and may appear brownish in spots on our blade. This is perfectly normal.

You'll also notice that we've developed some areas of purple-ish hue on the blade. Again this is normal for a temper at this heat and isn't a worry to us.

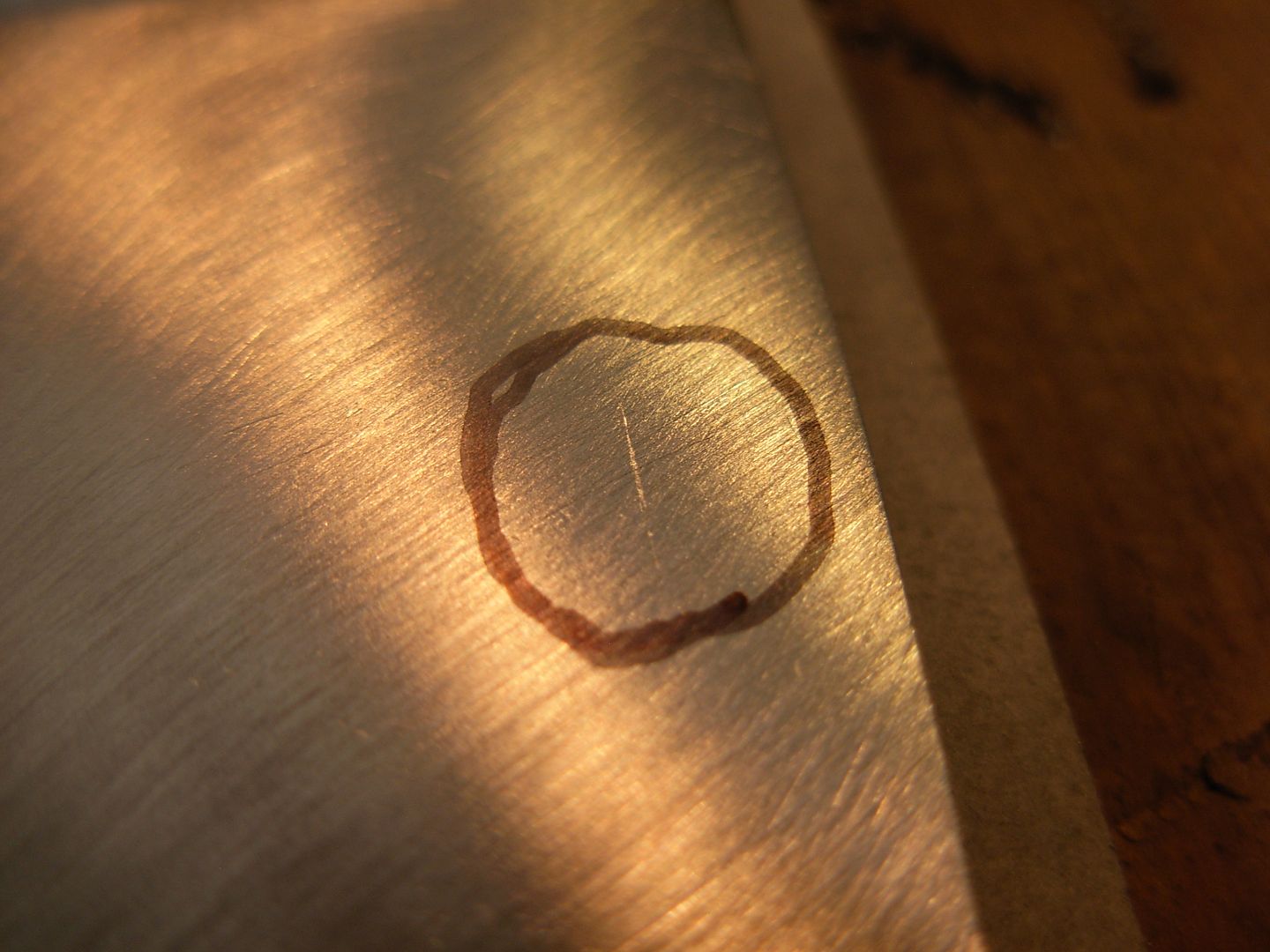

You may be wondering what causes the differing coloration on our tempered blade and the answer is simply contaminates on the surface of the steel. What exactly is "contaminating" our steel ?

-Crud from the quench. I did a quickie clean up but there is still residue from the oil present on the blade

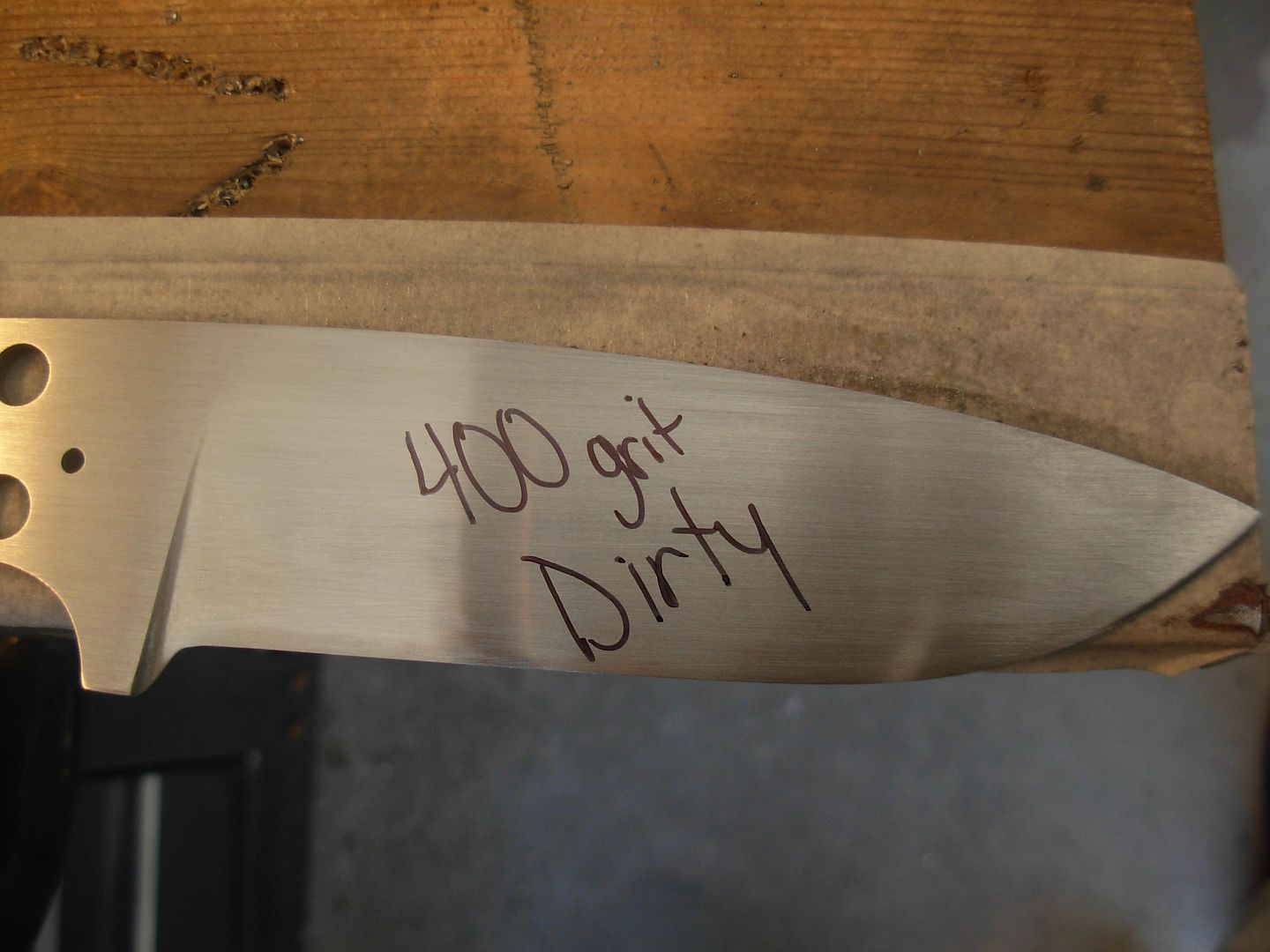

-Decarb. This happens when steel is exposed to very high heat like we reached in the hardening stage. In laymans terms- the carbon on the surface of the steel attaches to oxygen in the air and actually seperates from the steel itself leaving behind "decarb" or a thin layer of steel that has lost it's carbon. This is on the surface only and not to worry about. The point here is that we do have some decarb here and it will affect how our blade oxidizes in the temper.

-Oil from our hands. I don't know about you but I just can't resist playing with my blade once it cools down from the first temper. I never bother to clean the blade between tempers and due to this the natural oils from your skin are left on the blade for the second tempering cycle. This definately has an effect on the colors present after the second temper and we can clearly see evidence of this in the purple finger prints on the blade

One more time, None of this is alarming to me and this blade looks exactly as I expect it to with our heat treating completed.

It is now official that we have made our first knife blade.

Congratulations on completing Stage 2 of our Knifemaking process !!!!

-Josh

Whenever we're talking about heat and steel there are two main factors that have an effect on the steel TIME & TEMPERATURE

On our second tempering cycle we have not raised the temperature from our first cycle. However, our blade is going to look quite different after the second temper due to the TIME our blade has been exposed to the 400 degree heat. Because of this we're going to see a much bolder coloring of our steel which is to be expected.

Our gold coloring had deepened a little and may appear brownish in spots on our blade. This is perfectly normal.

You'll also notice that we've developed some areas of purple-ish hue on the blade. Again this is normal for a temper at this heat and isn't a worry to us.

You may be wondering what causes the differing coloration on our tempered blade and the answer is simply contaminates on the surface of the steel. What exactly is "contaminating" our steel ?

-Crud from the quench. I did a quickie clean up but there is still residue from the oil present on the blade

-Decarb. This happens when steel is exposed to very high heat like we reached in the hardening stage. In laymans terms- the carbon on the surface of the steel attaches to oxygen in the air and actually seperates from the steel itself leaving behind "decarb" or a thin layer of steel that has lost it's carbon. This is on the surface only and not to worry about. The point here is that we do have some decarb here and it will affect how our blade oxidizes in the temper.

-Oil from our hands. I don't know about you but I just can't resist playing with my blade once it cools down from the first temper. I never bother to clean the blade between tempers and due to this the natural oils from your skin are left on the blade for the second tempering cycle. This definately has an effect on the colors present after the second temper and we can clearly see evidence of this in the purple finger prints on the blade

One more time, None of this is alarming to me and this blade looks exactly as I expect it to with our heat treating completed.

It is now official that we have made our first knife blade.

Congratulations on completing Stage 2 of our Knifemaking process !!!!

-Josh

Last edited: