I saw a post by a knifemaker recently that also engraves. I wish I could recall who it was and credit him for the reminder but here it is.

Engravers use several methods to transfer a sketch to the work piece for engraving.

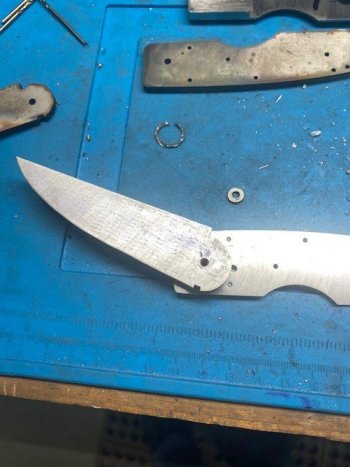

Below I have the printed out a pattern and cut out the blade and frame for transferring.

Using a clean piece of steel place your pattern, ink side down and rub it lightly with a rag soaked in acetone. The acetone wets the paper and ink and then with the mild rubbing transfers some of the ink to the steel. It is a durable transfer and this method can be used instead of gluing paper to the steel.

View attachment 76663

The technique is fairly easy. Hold down the paper as flat as possible and rub an acetone soaked rag or paper towel across the back wetting out the paper. It won't take much effort or time. If you rub too much it will smear. Usually one quick stroke is all that is needed. Carefully peel away the paper so it doesn't smear or wait until it is dry which takes just a few seconds.

View attachment 76664

One thing to consider is the pattern will appear backwards from the paper copy. In many cases this won't matter when it is a profile and through holes.

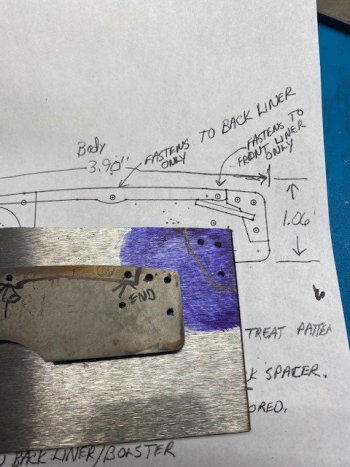

In engraving a backwards pattern is usually a problem so it is reversed in software first and then printed out for use as a transfer.

This doesn't work with all printers but it will work with most. Set your printer to print just black as colors and color composites do not transfer as well. Some printer ink just doesn't like this method but it takes just seconds to try it. The transfer can be removed easily with a swipe of acetone.

Many printers today can scan. If you have a hand drawn sketch, scan your sketch and print the scan. You can then transfer your hand sketch printout to your steel.

View attachment 76665