You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pass around!!!

- Thread starter franklin

- Start date

Mya Knives, Franklin

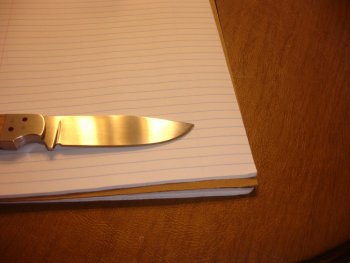

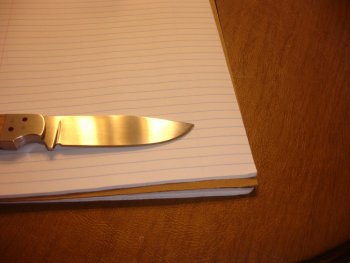

There is a lot to like about this knife. Very functional blade shape and design. Nicely executed bolsters, especially for a first attempt.

The only con’s I could really see are more a difference of opinion as a maker than a flaw in the knife itself. Personally, I found the handle area to be a bit short. I have fairly large hands and while I was able to achieve a full grip, it was awkward and cramped. I found the finger cut out on the end of the handle to be awkward also.

I found the finger cut out on the end of the handle to be awkward also. I would have treated the lightly colored Olivewood grips with some sort of sealer or CA finish. Because it’s so light that over time, and with handling, the wood would develop a dirty appearance that would detract from the overall appeal if left unprotected. Some people may call this a patina and prefer it, but I for one do not. As has been mentioned, once I had noticed the area on the tip of the right side of the blade where it had touched a belt, I couldn’t forget about seeing it.

I would have treated the lightly colored Olivewood grips with some sort of sealer or CA finish. Because it’s so light that over time, and with handling, the wood would develop a dirty appearance that would detract from the overall appeal if left unprotected. Some people may call this a patina and prefer it, but I for one do not. As has been mentioned, once I had noticed the area on the tip of the right side of the blade where it had touched a belt, I couldn’t forget about seeing it. Is that enough to detract from the usability of the knife? No, it is not. I also noticed on the bolsters, that the pin material was not the same as the bolster material and were easily seen.

Is that enough to detract from the usability of the knife? No, it is not. I also noticed on the bolsters, that the pin material was not the same as the bolster material and were easily seen. Again, it’s more a difference of opinion in execution than something that would detract from the usability of the knife. I would have flared the ends of the tubes to make them more secure as a means of holding the grip material in place.

Again, it’s more a difference of opinion in execution than something that would detract from the usability of the knife. I would have flared the ends of the tubes to make them more secure as a means of holding the grip material in place.

The edge was not as sharp as I would have liked but was definitely serviceable. In my very limited testing, I found it to be enough to do everything I wanted it to do. I was able to slice thin sections of paper while holding it. I also found it to be quite capable to slicing small pieces of 8-9 ounce leather using push cuts from a piece of scrap I had laying around.

I also found it to be quite capable to slicing small pieces of 8-9 ounce leather using push cuts from a piece of scrap I had laying around. It also went through cardboard with ease, and opened a few packages.

It also went through cardboard with ease, and opened a few packages.

The fit between knife and sheath was extremely well executed. Good retention of the blade but still easily drawn. Some of the lines wander on the sheath, but that is totally, a cosmetic flaw. The construction and stitching is as it should be and provides a comfortable way to carry the knife on a belt.

At the end of the day, MYA knives is supplying a rock solid tool that is meant to be used and look good while doing it. I would not hesitate to recommend MYA knives And the above is strictly MY OPINION, and you may feel totally different about my observations.

P.S. My photography skills are seriously lacking.

There is a lot to like about this knife. Very functional blade shape and design. Nicely executed bolsters, especially for a first attempt.

The only con’s I could really see are more a difference of opinion as a maker than a flaw in the knife itself. Personally, I found the handle area to be a bit short. I have fairly large hands and while I was able to achieve a full grip, it was awkward and cramped.

I found the finger cut out on the end of the handle to be awkward also.

I found the finger cut out on the end of the handle to be awkward also. I would have treated the lightly colored Olivewood grips with some sort of sealer or CA finish. Because it’s so light that over time, and with handling, the wood would develop a dirty appearance that would detract from the overall appeal if left unprotected. Some people may call this a patina and prefer it, but I for one do not. As has been mentioned, once I had noticed the area on the tip of the right side of the blade where it had touched a belt, I couldn’t forget about seeing it.

I would have treated the lightly colored Olivewood grips with some sort of sealer or CA finish. Because it’s so light that over time, and with handling, the wood would develop a dirty appearance that would detract from the overall appeal if left unprotected. Some people may call this a patina and prefer it, but I for one do not. As has been mentioned, once I had noticed the area on the tip of the right side of the blade where it had touched a belt, I couldn’t forget about seeing it. Is that enough to detract from the usability of the knife? No, it is not. I also noticed on the bolsters, that the pin material was not the same as the bolster material and were easily seen.

Is that enough to detract from the usability of the knife? No, it is not. I also noticed on the bolsters, that the pin material was not the same as the bolster material and were easily seen. Again, it’s more a difference of opinion in execution than something that would detract from the usability of the knife. I would have flared the ends of the tubes to make them more secure as a means of holding the grip material in place.

Again, it’s more a difference of opinion in execution than something that would detract from the usability of the knife. I would have flared the ends of the tubes to make them more secure as a means of holding the grip material in place.The edge was not as sharp as I would have liked but was definitely serviceable. In my very limited testing, I found it to be enough to do everything I wanted it to do. I was able to slice thin sections of paper while holding it.

I also found it to be quite capable to slicing small pieces of 8-9 ounce leather using push cuts from a piece of scrap I had laying around.

I also found it to be quite capable to slicing small pieces of 8-9 ounce leather using push cuts from a piece of scrap I had laying around. It also went through cardboard with ease, and opened a few packages.

It also went through cardboard with ease, and opened a few packages.

The fit between knife and sheath was extremely well executed. Good retention of the blade but still easily drawn. Some of the lines wander on the sheath, but that is totally, a cosmetic flaw. The construction and stitching is as it should be and provides a comfortable way to carry the knife on a belt.

At the end of the day, MYA knives is supplying a rock solid tool that is meant to be used and look good while doing it. I would not hesitate to recommend MYA knives And the above is strictly MY OPINION, and you may feel totally different about my observations.

P.S. My photography skills are seriously lacking.

Last edited:

franklin

Well-Known Member

Hey dogs if your following along chime in, do you like small edc knives. What handle style do you prefer on a smaller edc? Or perhaps you would rather a 3 finger handle?

Come on guys help a dog out! All comments welcome you don't have to be one of the guys testing to jump in and if you are a beginner and have a question

about something I did on the knife shoot I will try to give a reason. I can learn just as much by answering something as well as someone pointing something out.

Hope to see others doing this later down the road.

Come on guys help a dog out! All comments welcome you don't have to be one of the guys testing to jump in and if you are a beginner and have a question

about something I did on the knife shoot I will try to give a reason. I can learn just as much by answering something as well as someone pointing something out.

Hope to see others doing this later down the road.

franklin

Well-Known Member

Well guys just to show I do take head what I hear. This is a sheath I just did for a bowie I made don't now if I have showed the bowie

but think the sheath went well. Still need to work on the back side a little more but hey baby steps Still need to clean the leather burs on back and

Still need to clean the leather burs on back and

decide how to cut end of strap so still needs a little work.

but think the sheath went well. Still need to work on the back side a little more but hey baby steps

decide how to cut end of strap so still needs a little work.

Attachments

Last edited:

Franklin, the knife is on it's way to Scott. Sorry for the delay in getting it sent out!

As far as my thoughts on the knife:

Overall, I think this is a good quality knife. I noticed the spot on the tip of the blade and along the spine independent of the other reviews as I had not read them yet. I assumed that it had happened while someone else was testing it. It may have been an issue of looking at it under just one light source I didn't do any specific testing but I did use it whenever I needed something sharp including some rope, cardboard and in the kitchen some. I believe the edge held up pretty good overall. As far as the handle, I have pretty small hands so it was nice to have a knife with a blade that size that didn't have too large a handle for me to have a comfortable grip. That's pretty uncommon for me to come across. The only other thing I saw with the knife that was pretty noticeable was that the front pin seemed to have some fitting issue. If this had been a knife I had made, that would drive me crazy, but as just a user it didn't bother me too much since I didn't put the time in making it. :biggrin:

Overall, I found this knife(and the sheath, as well) to be very well made and enjoyed getting to see it and use it. Thank you, Franklin.

Also, I did not resharpen the knife as I am relatively new and didn't want to risk messing it up. The edge should still be fairly sharp as I did not work it too hard.

As far as my thoughts on the knife:

Overall, I think this is a good quality knife. I noticed the spot on the tip of the blade and along the spine independent of the other reviews as I had not read them yet. I assumed that it had happened while someone else was testing it. It may have been an issue of looking at it under just one light source I didn't do any specific testing but I did use it whenever I needed something sharp including some rope, cardboard and in the kitchen some. I believe the edge held up pretty good overall. As far as the handle, I have pretty small hands so it was nice to have a knife with a blade that size that didn't have too large a handle for me to have a comfortable grip. That's pretty uncommon for me to come across. The only other thing I saw with the knife that was pretty noticeable was that the front pin seemed to have some fitting issue. If this had been a knife I had made, that would drive me crazy, but as just a user it didn't bother me too much since I didn't put the time in making it. :biggrin:

Overall, I found this knife(and the sheath, as well) to be very well made and enjoyed getting to see it and use it. Thank you, Franklin.

Also, I did not resharpen the knife as I am relatively new and didn't want to risk messing it up. The edge should still be fairly sharp as I did not work it too hard.

franklin

Well-Known Member

thanks akey glad you had fun with it and that pin thing is driving me nuts I did not see what you guys are talking about when I get this puppy back

you can be sure I will be going threw it and finding each and every thing. The spot on the tip I think I did while doing a fast clean up before I shipped

it out and missed seeing it, But did not notice this pin thing so cant wait to see it.

you can be sure I will be going threw it and finding each and every thing. The spot on the tip I think I did while doing a fast clean up before I shipped

it out and missed seeing it, But did not notice this pin thing so cant wait to see it.

scott.livesey

Dealer - Purveyor

just received the knife this evening when i got home from the office. just opened the almost sailor proof packaging. the knife/sheath are a nice pair. sheath looks good. knife looks, outstanding fit and finish. I have large hands, so the handle feels a little short. two finger pinch grip doable.

will post more later

will post more later

Last edited:

just opened the almost sailor proof packaging.

HAHAHA. Sorry about that Scott! Not my knife so I was extra concerned about it getting there in the condition it left in.

A.W.Stovall

Well-Known Member

I have it now I will try and do some action shots my first look at it I like the overall size of the knife. I thought the blade was a little thick but it wasn't I ran it through a quick cutting session with leather ,cardboard and foam. I have on question What kind of etcher do you use to put your logo on that was so crisp and sharp I just cant get my etcher to do that ? I'll write up a better review after I have used it for a few days.

Anthony

Anthony

backtines

Well-Known Member

Here's my personal review on the knife.. Understanding that this was the first time you made a knife with bolsters, I think they came out ok for the first time. I noticed the pin stock was not the same as the bolster material, and a bit of the pin holes showing. The rounded face sides of the bolsters looks like you could have went through a few higher grits to make the finish a bit smoother . I also noticed the same could have been done on the belly of the knife. Just a little more time going up it grits would have gave the spine, belly and bolster fronts a cleaner finish..

The satin finish on the bevels came out real nice as well as the logo.. Plunges look good. Finger grooves fit my hand. It actually fit my hand pretty nice.

I have a few things that I always try to strive for when I make my knives and the one thing that I learned from listening to the great Bob Loveless is , is the rounded edges. I always try to round off all the edges, And try to blend them into the material. So I always use scales that are thicker then normal as well as my bolster material. Going thicker gives me some room to round everything off..

I love the design and shape of the knife. I thought all the tubes looked cool in the handle and bolster . I think the tubes in the handle could have come down a bit for a better center appearance .

The knife fit well in the sheath and felt real comfortable on my hip. In fact I wore it to work today and cut up about 40 to 50 cardboard boxes and opening up a pile of them too.

Sorry to ramble on here, but Im just trying to be straight with you. I think you made a fantastic, well functional knife. I put it to work today and worked well. It didn't come to me super sharp nor did I want it super sharp and for what I used it for today , it worked perfect.

Putting aside all the little cosmetic things I brought up The one thing that I noticed the most using your knife was the square corners on the handle and the bolsters. I would say if the edges were more rounded off it would have felt a lot more comfortable .

I tell ya bro. I can't really beat up your job because you made a nice little knife. I think if you spend a little more time in those areas , you'll have a better product overall..

My two cents and being 100 percent honest with you. Good job!

The satin finish on the bevels came out real nice as well as the logo.. Plunges look good. Finger grooves fit my hand. It actually fit my hand pretty nice.

I have a few things that I always try to strive for when I make my knives and the one thing that I learned from listening to the great Bob Loveless is , is the rounded edges. I always try to round off all the edges, And try to blend them into the material. So I always use scales that are thicker then normal as well as my bolster material. Going thicker gives me some room to round everything off..

I love the design and shape of the knife. I thought all the tubes looked cool in the handle and bolster . I think the tubes in the handle could have come down a bit for a better center appearance .

The knife fit well in the sheath and felt real comfortable on my hip. In fact I wore it to work today and cut up about 40 to 50 cardboard boxes and opening up a pile of them too.

Sorry to ramble on here, but Im just trying to be straight with you. I think you made a fantastic, well functional knife. I put it to work today and worked well. It didn't come to me super sharp nor did I want it super sharp and for what I used it for today , it worked perfect.

Putting aside all the little cosmetic things I brought up The one thing that I noticed the most using your knife was the square corners on the handle and the bolsters. I would say if the edges were more rounded off it would have felt a lot more comfortable .

I tell ya bro. I can't really beat up your job because you made a nice little knife. I think if you spend a little more time in those areas , you'll have a better product overall..

My two cents and being 100 percent honest with you. Good job!

franklin

Well-Known Member

Thanks Mikey nice write up. If there is one thing I am working hard on is slowing down and trying harder on

fit and finish. The only thing that I will say is I put different pin stock in the bolster for the reason, I thought it would off set

the tubes and it would look more even I thought well maybe not. Thanks for the tip on the rounded edges on bolsters was not

well maybe not. Thanks for the tip on the rounded edges on bolsters was not

sure if I would be doing more but I sure might. This pass around in all guys I think has showed me a lot and I would recommend any

one who is not sure were they need to improve try one it will help. The guys are not mean or out to cut you up, they really do want to

help and give you advise so this has been a blast one more and we will be at a end.

fit and finish. The only thing that I will say is I put different pin stock in the bolster for the reason, I thought it would off set

the tubes and it would look more even I thought

sure if I would be doing more but I sure might. This pass around in all guys I think has showed me a lot and I would recommend any

one who is not sure were they need to improve try one it will help. The guys are not mean or out to cut you up, they really do want to

help and give you advise so this has been a blast one more and we will be at a end.