Dwane Oliver

Well-Known Member

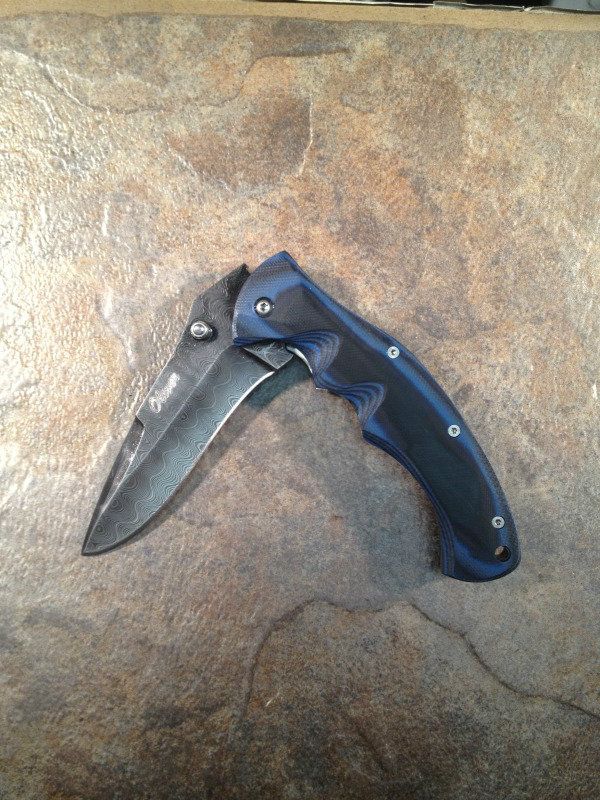

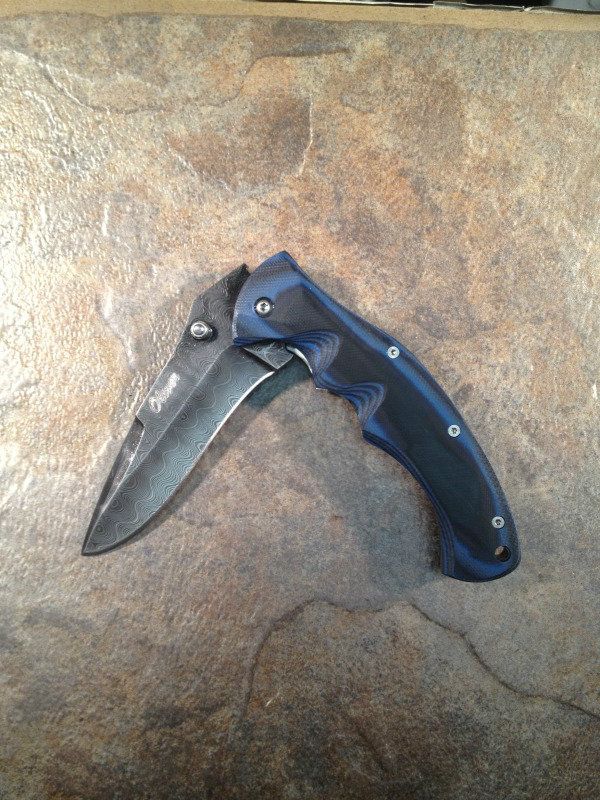

I have made 2 linerlocks in my whole time , this one being the 3rd.

I wanted to make one that would be a bit more affordable, but still uses top quality materials, I think I will have achieved that goal.

I came up with this design, a bit stole from a POS EDC I had , and the rest from my imagination.

8.5" OAL , 3.875" Blade that is .154" thick , .050" Ti liners , a piece of crappy damascus I had laying around, that hardened well ( the rest of them will be CPM S30V ) and G10 handle material.

Here is the question I have had since doing some research on the web.

Why do they say the detent should be taller than the washers used on the pivot ?

THanks for looking

I wanted to make one that would be a bit more affordable, but still uses top quality materials, I think I will have achieved that goal.

I came up with this design, a bit stole from a POS EDC I had , and the rest from my imagination.

8.5" OAL , 3.875" Blade that is .154" thick , .050" Ti liners , a piece of crappy damascus I had laying around, that hardened well ( the rest of them will be CPM S30V ) and G10 handle material.

Here is the question I have had since doing some research on the web.

Why do they say the detent should be taller than the washers used on the pivot ?

THanks for looking