SHOKR

Well-Known Member

hey guys

instead of creating a new thread for every knife i'll just post the ones i finish here, unless i do something special

pointers and comments are welcome

starting with the sixth (rest are in other threads)

this one has LOTS of bobo's...

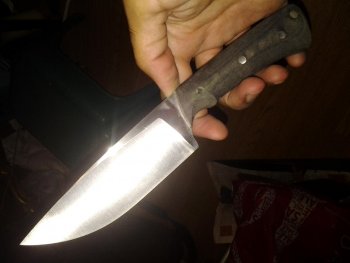

4.7mm O1 steel, red and black G10 handle. my first tapered tang to finish (slight taper tho)

instead of creating a new thread for every knife i'll just post the ones i finish here, unless i do something special

pointers and comments are welcome

starting with the sixth (rest are in other threads)

this one has LOTS of bobo's...

4.7mm O1 steel, red and black G10 handle. my first tapered tang to finish (slight taper tho)