Gliden07

Well-Known Member

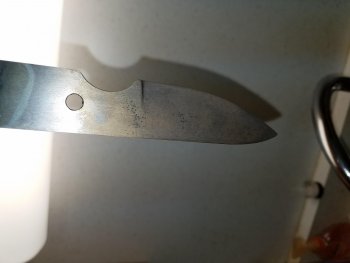

I was going to wait and get more work done on this First Project but what the heck! Its a small blade about 6" long made from 1/8"x 1"- 01 tool steel, Black Micarta scales. Since taking these pics I have done some more sanding, reshaped the front of the scales to match the plunge line and changed the pins over to 1/4" SS steel. I figure I'm about halfway done? Need to finish sand, blade, harden, temper etc... etc... ok 1/3 done!! I filed all this by hand and think I will make a file jig for my next project to help with the plunge. This has really been a lot of fun and I want to finish it but time is at a premium right now. Any comments from you guys in the know would be helpful. Thanks!!