Stang Bladeworks

KNIFE MAKER

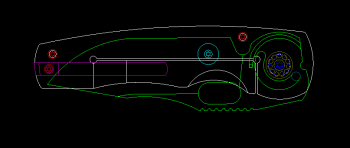

I am in the process of designing my first framelock. I have modified my design a bit. And im in the process of choosing all the hardware and tooling. I want to have shouldered standoffs and a shouldered stop pin to help with lateral rigidity. I also plan to use a hinderer style stabilizer. All the counterboring seems simple for the bearings and pivot. Drill and ream to the pivot size then use a pilot counterbore to set the depth. My issue is when a pilot is not available. I want to use hardened solid stop pins. I see some people have tiny holes visible on the outside of their knives for the stop pins. I assume that those pin holes are from waterjet used to locate the placment. I am wondering how they are drilled to size for the stop pin. I cant find any counterbores that small. Do you use a twist drill then bore down? Im all ears. Any tips or methods are greatly appreciated. Similarly I have the same issue when I look for tooling to shoulder the stop pins. I hope my question is clear enough. Basically how do you shoulder your stop pins and standoffs when no pilot counterbore is available?

Thanks.

Thanks.