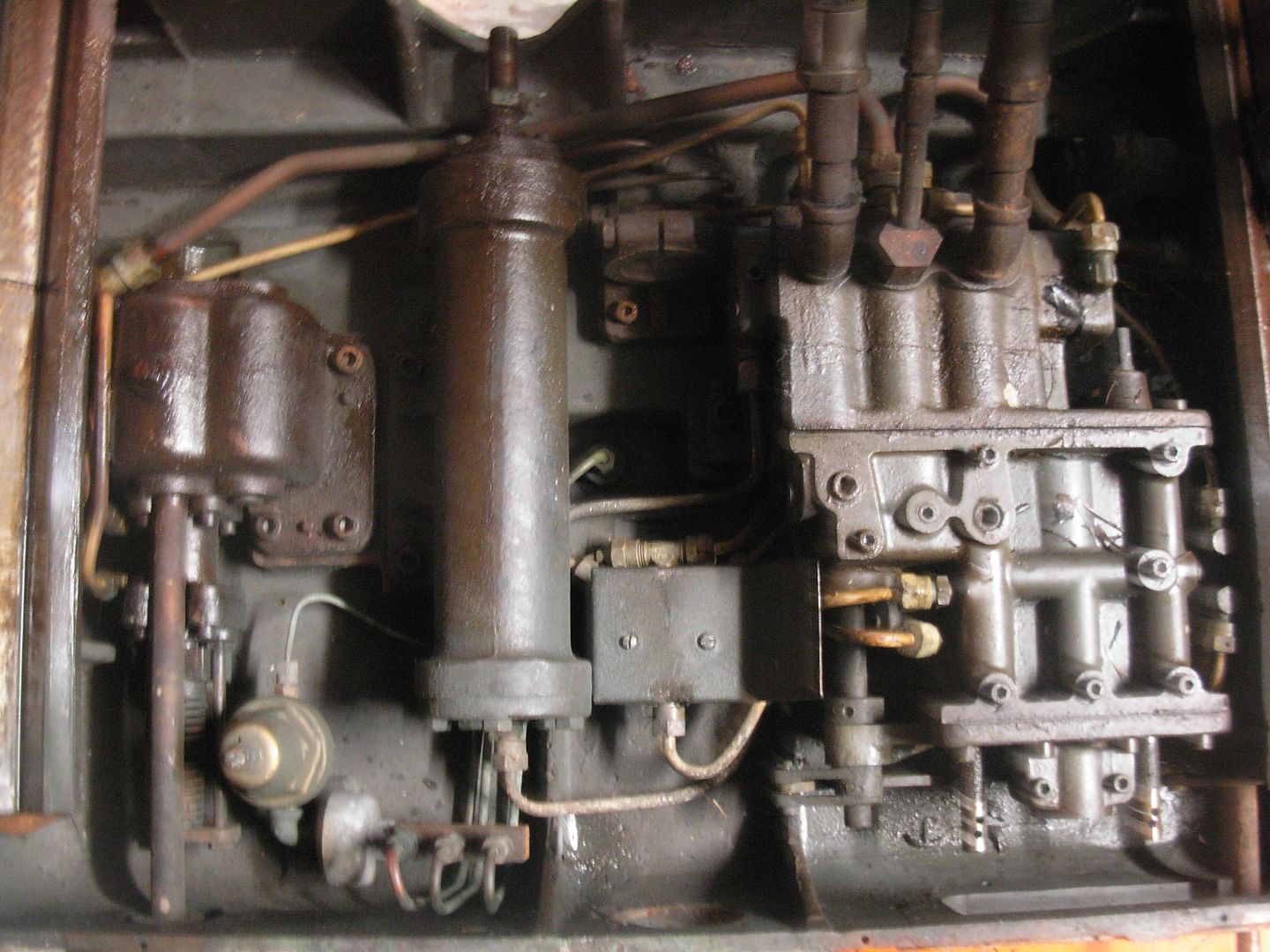

Eric, I'm not planning to disassemble the inside of the cabinet and remove it. I'm planning to just give everything a light degreasing once I get into opening up the tank for cleaning and filter replacement. All appears in good shape in the cabinet just oily and dusty.

One thing I must do is make absolutely certain my oil passages to the ways are clear. It's evident after removing the saddle that the left side saddle ways are not getting the oil they should.

It's taken me a little studying to fully understand how the oiler system operates and I probably never would've got it if not for a small clue found in a thread I was reading about a similar machine. The main point learned there is- There are no oil lines for lubricating the saddle ways.

For proper lubrication of the ways the oil follows this path-

-Pressured supply line from the main combination valve goes to the oil regulator.

-From regulator through screen filter.

-From filter to manifold that splits the supply into 3 lines.

-1 line provides oil to the flat table way. The other two provide oil to the tables vee way (one on each side of the vee)

This is where the physical lines end.

From there the excess oil from the table ways follows the oil channels on the sides of the flat way and the bottom of the vee way and goes to the left and right ends of the saddle where it collects in depressions.

There is a hole in each depression that allows the oil to drain through the saddle casting and end up right in the center of the saddle ways.

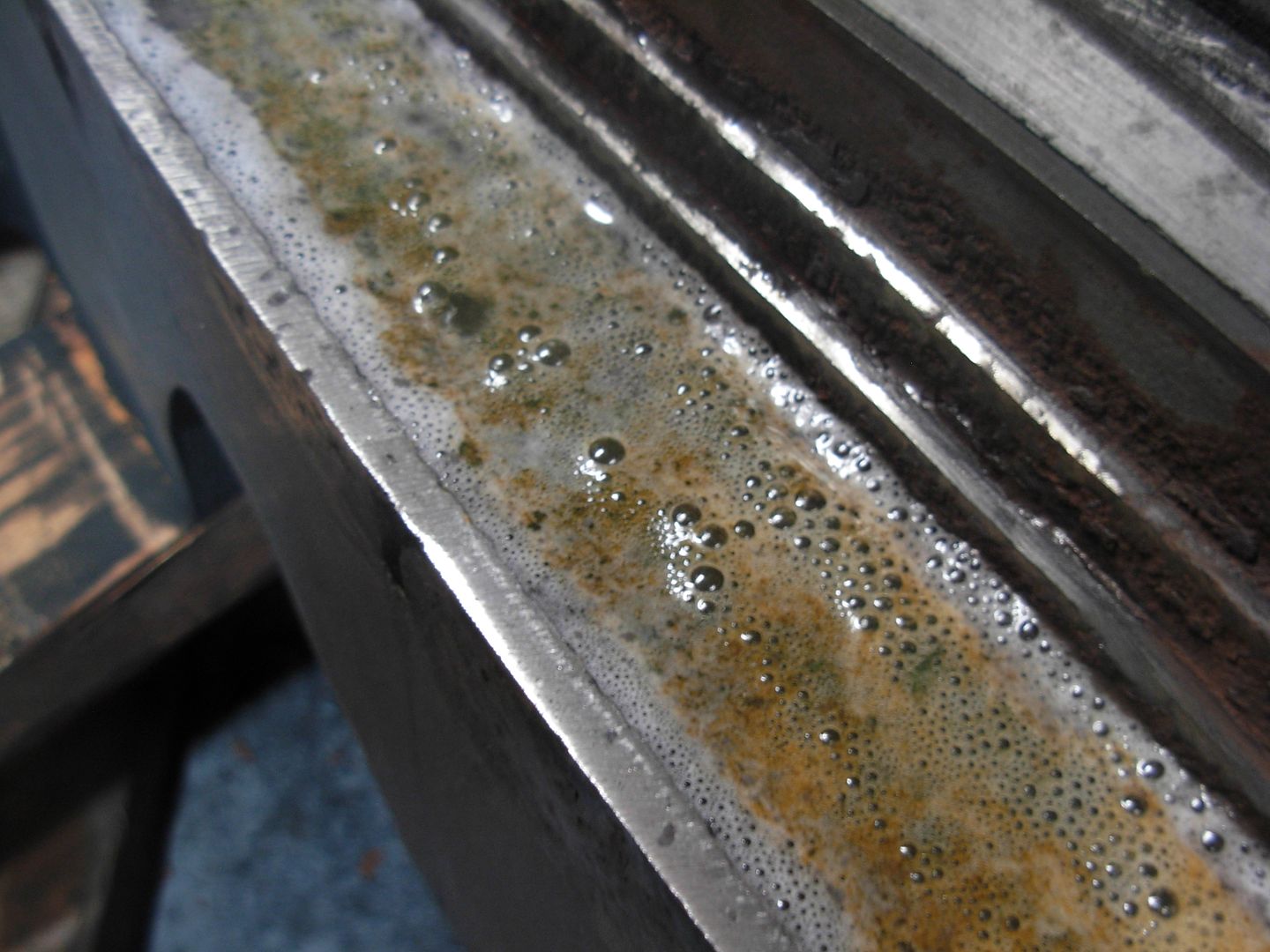

Excess run off from the saddle ways follows the oil channels cast around the ways on the cabinet and drain into the return lines that lead to the glass bowl filter which drains back into the tank to complete the oils travel through the system.

I've already cleaned out the entire oil path except for inside the combination valve ( which will only be flushed with clean oil once reassembled ) and the oil channels that go through the casting from the depressions to the saddle ways.

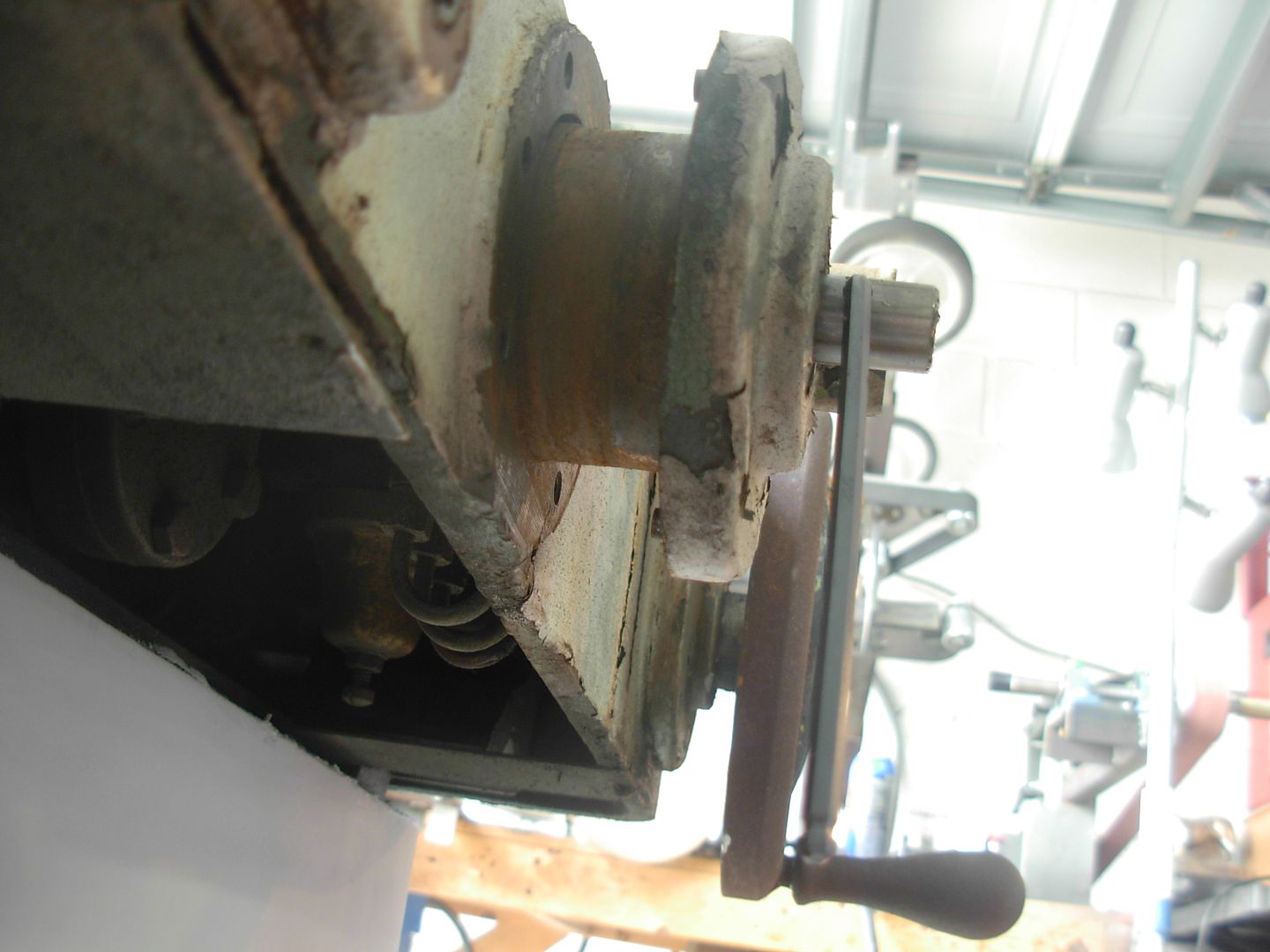

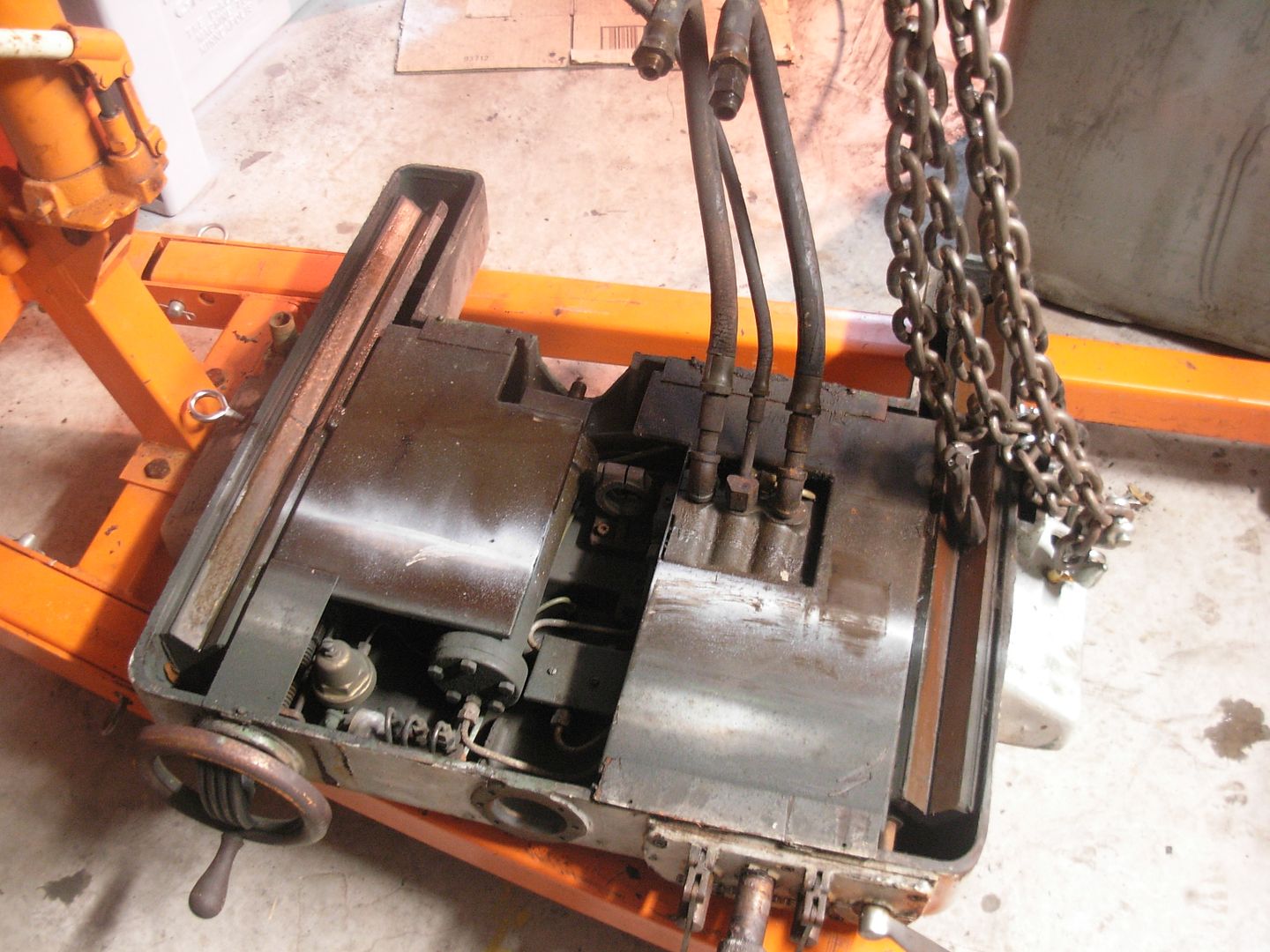

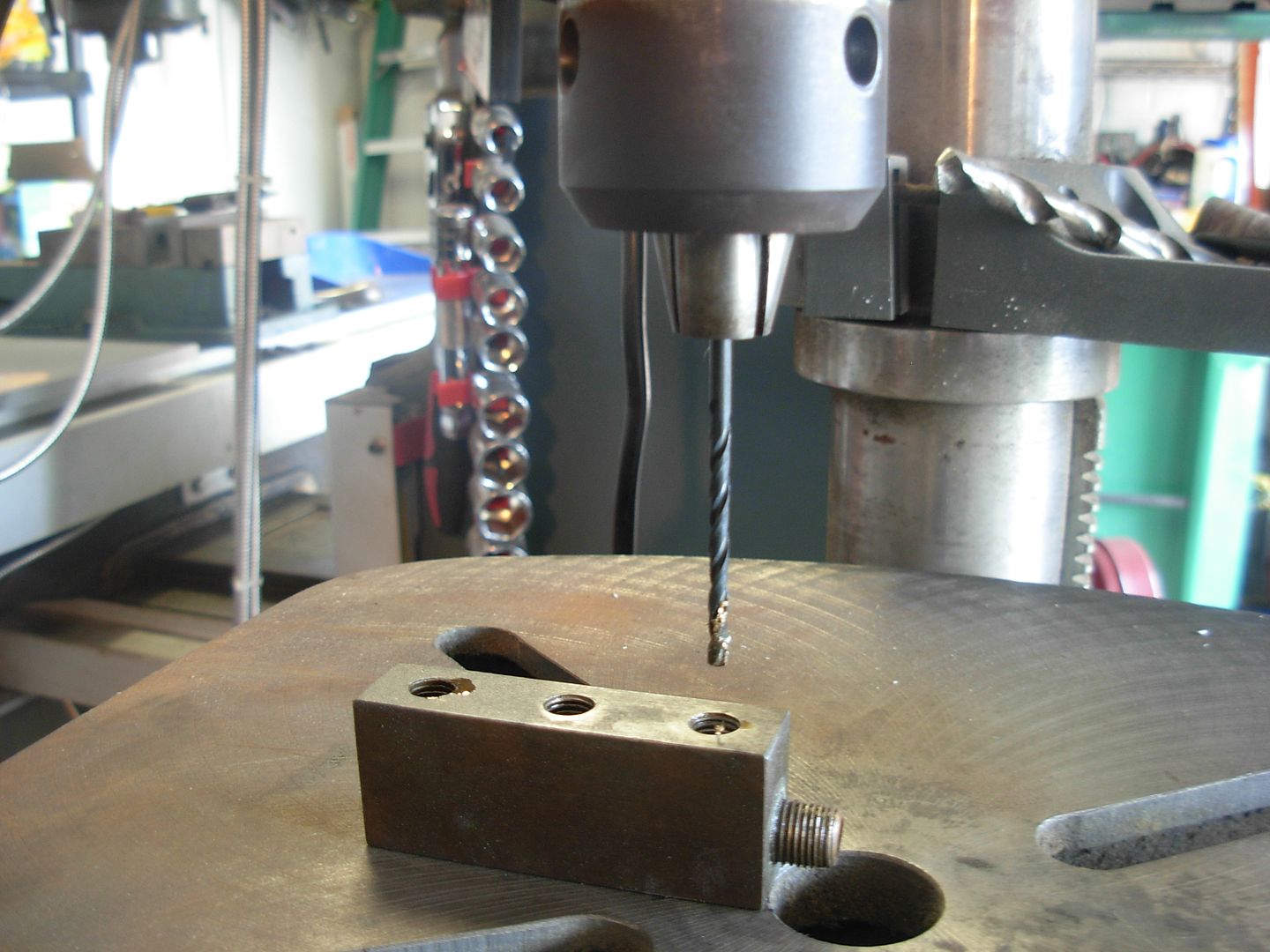

To clean thes channels and be absolutely sure the oil path is unobstructed I wanted to reposition the saddle on my hoist to get it relatively level and in the air so I'd have access to the top and bottom sides.

I'm no professional rigger but this is what I did which worked out really well. I set the saddle down and repositioned one hook so both my lifting hooks are the same number of links from the lift point. Then I added a ratched strap for a 3rd point to act as my load leveller.

Just ran the strap through the screw hole so tightening up the ratchet levels out the saddle front and back

The wire is pointing at the depression hole that carries oil to the saddle ways. This side was clogged with loose paint and crud

Here's the other side. All this grit will end up flushed right onto the saddle ways because there's no filter or anything between here and those ways. A thorough cleaning of these areas had been done

Now I know 100% that all my oil passages are clean from the comination valve all the way back to the tank !

A bunch of paint and crud like this came out of those oil depressions. Only a matter of time before this gunk clogged up a passage starving the saddle ways of oil. I was curious about the bolts on the side of the saddle that I removed and installed the eye hooks in. Now it's obvious that these are clean-out ports for the oil passage so you do not have to remove the table to clean out a clogged passage.

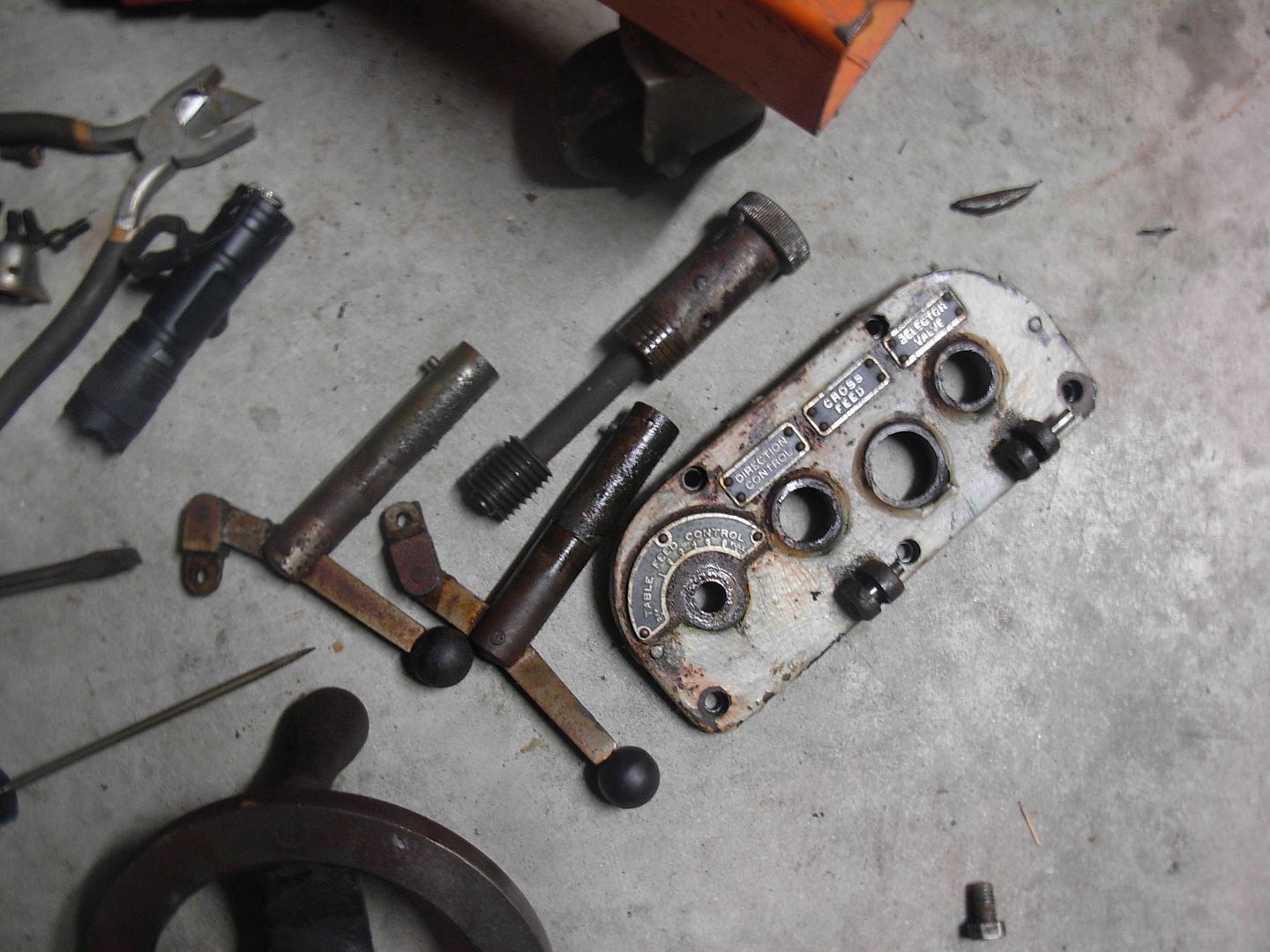

I spent the rest of the night wire brushing the parts in my vinegar soak. All looking good but I dropped them back in to looses some paint that's still on the center of the handwheels and the control levers and knob.

I did some running around this morning though and got some more oven cleaner so I should be able to strip that paint pretty easy now. Also got more paint, primer, and some thread sealant for reassembling my hydraulic lines and two replacement springs that retract the dist cover that keeps grinding dust out of the cabinet.

I'll be moving forward with stripping and de-rusting the table, saddle, and all the dust shields, brackets etc.

Once all that is done reassemble the machine and tackle draining and cleaning out the tank and figure out a filter solution for the tank.

Still alot to do before she's running again !

-Josh