Jeff, I have used that same machine for a couple of years now. It's a good investemnt at a reasonable price for turning handles and milling guards.

We are all excited when we add to our shop and I am not trying to rain on your parade but the machine does have some shortcomings and I'll offer what I have learned to maybe save you some headaches.

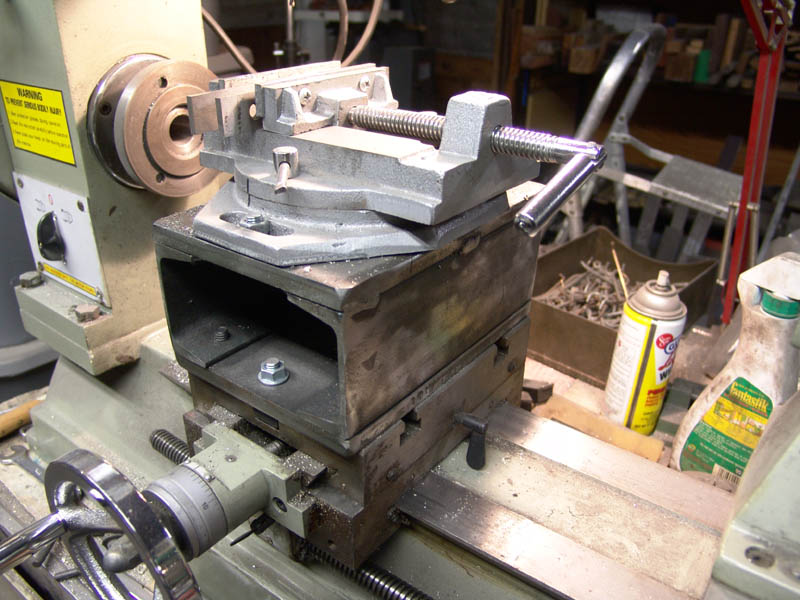

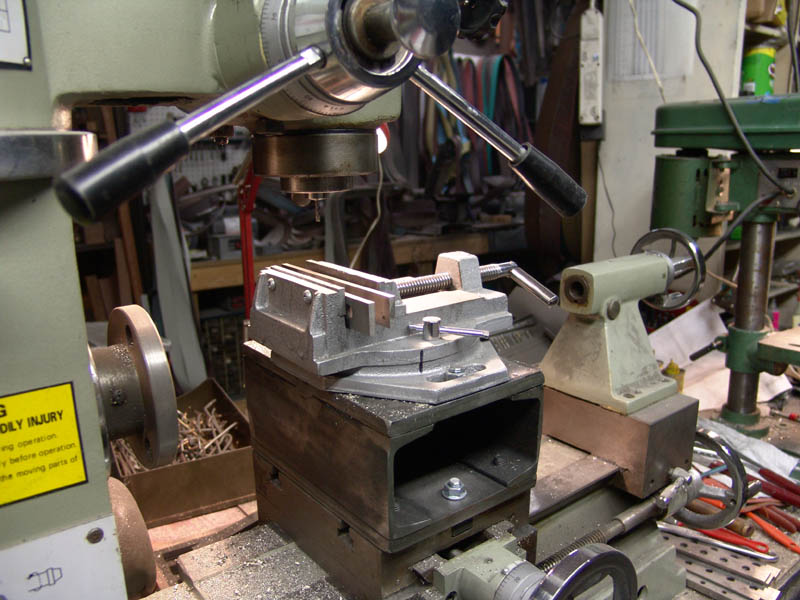

It comes with this universal vise with accessories for holding the lathe bits.

This OK for lathe work but the vise sucks for milling. I wanted to use a better mil vise.

Also the mill/drill head comes with a drill chuck. I changed to using collects which are more stable and precise.

Between changing the vise and removing the drill chuck, I found I had a new problem. Bolting a regular mill vise to the table lowered it about 3 inches. Likewise, replacing the drill chick with a collet loses about 3 inches. Since the mill head only has 3 1/2 inches of vertical travel, my bits wouldn't reach my work. I ended up having to make a riser to get my vise up within reach of the milling bits.

I also found that the lathe chuck prevented me from moving my work far enough to the left in some cases. I remove the lathe chuck to gain about 3 more inches of horizontal travel.

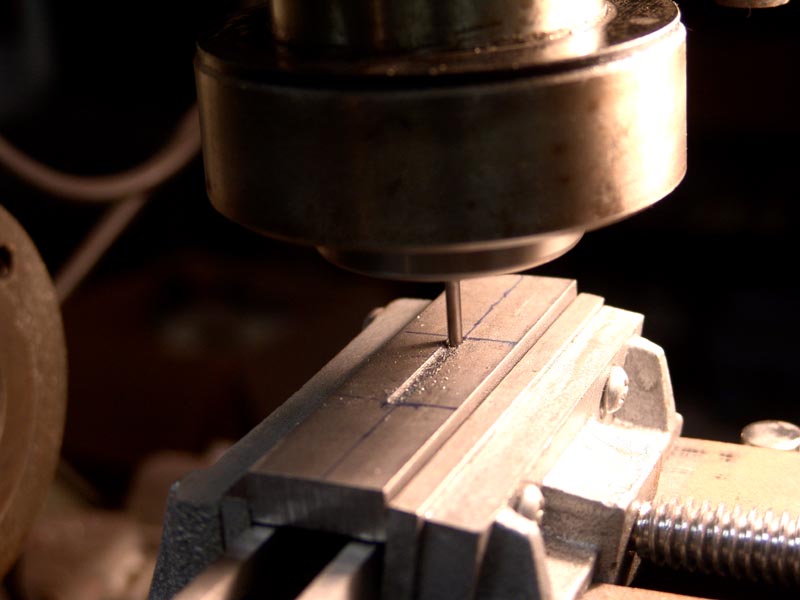

I have used this machine for over two years now. I mostly use it for milling slots in guards but I occasionally turn a knife handle on the lathe.

It does all functions OK but none of them great. If you really crank down on the mill it can move and for precision pieces that's a problem. You definitely need to lock things down with the various locks for anywhere near precise results. It can be rather time consuming to change things around to go from milling to lathe work. If I were to do it all over again I would buy a dedicated milling machine rather than a multipurpose machine even though the mills tend to run 2x - 3x the price.

After 2+ years of moderate use, the mill motor quit working. (It has separate motors for the mill and lathe) I called the 1-800 service number on the front of the owners manual and to my surprise a real live person answered the phone, immediately looked up the correct part, and quote a price if $84 shipped to my door. I received the replacement motor in 2 or 3 days. I felt the motor should have lasted longer but I am impressed with the customer service. However, after about two months the replacement motor died. I called again and they shipped me another motor at no charge. So far it is still working after a couple of weeks.

Good luck and have fun.