You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A. Cole Photo Gallery

- Thread starter Alden Cole

- Start date

Alden Cole

Well-Known Member

Alden Cole

Well-Known Member

Alden Cole

Well-Known Member

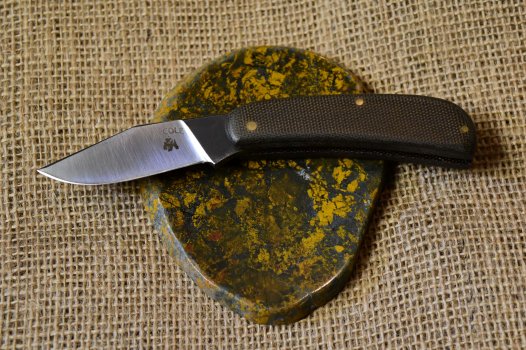

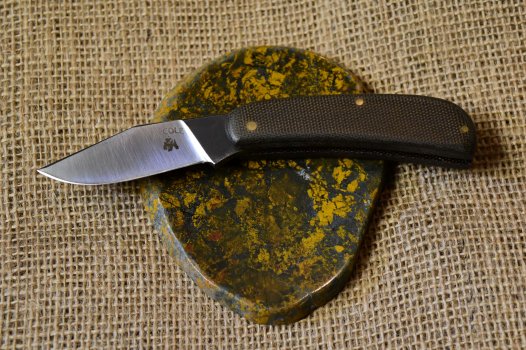

First folding knife that I built from scratch. D2 and green micarta. This one didn't turn out great, but it wasn't as bad as I thought it would. If you are used to making fixed blades and are interested in stepping off into folders, I would highly recommend trying your hand at a spring back (slipjoint) folder. The makers mark is actually clear, the picture just messed with it.

Alden Cole

Well-Known Member

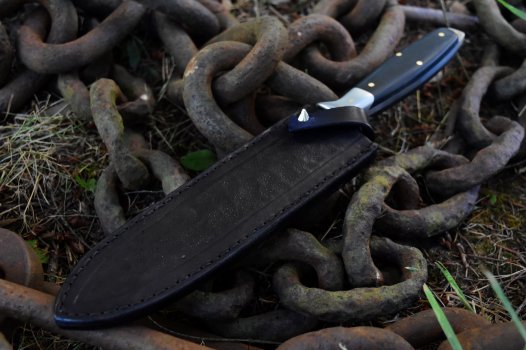

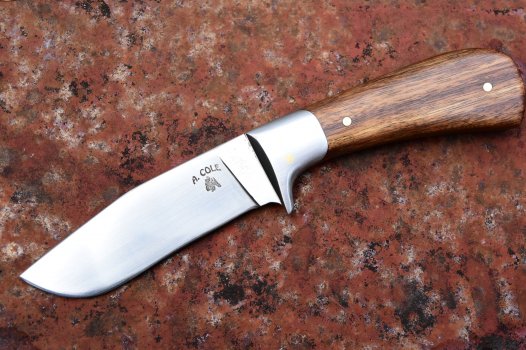

These were a couple Classic hunters. I wanted to make these after reading some old books by Loveless, Dozier, etc. On the lacewood's sheath, I found that dying all the edges of your sheath really gives it a professional look, at least in this case. Because of the way the guards are, you can design the welt so that the knife snaps in place. I obviously took that from the other makers before me, but had never implemented it to this effect.

Alden Cole

Well-Known Member

Alden Cole

Well-Known Member

Alden Cole

Well-Known Member

Here a couple clip point hunters. Dovetailed bolsters and tapered tangs. You probably realize that I do a lot of dovetailed bolsters. That's because they form a mechanical bond that holds the handle slabs on. Not that I'm worried about the epoxy failing, but you know... And they look cool. I think I ground the top one too thick, which is a bummer. The bottom one was probably a little thick too. It was a custom order and has more handle pieces than I've ever used in a knife.

Alden Cole

Well-Known Member

Alden Cole

Well-Known Member

Alden Cole

Well-Known Member

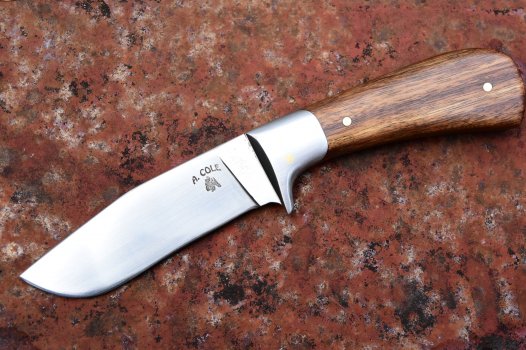

Finally to the most recent knife! This was a custom order and the new owner says he really likes it. Sculpted zebrawood handle (from the owners G-Pa.) D2 blade, which was probably not the best steel choice on my part, but should work. It is 11.5 in. long. The sheath idea was stolen from Free Hill Blades, it can be worn vertically or horizontally. And dog.

Sean Jones

Well-Known Member

Nice work on all of them!

Alden Cole

Well-Known Member

Thank you. I try to take as accurate pictures as I can, but sometimes the camera hides flaws.Nice work on all of them!

Alden Cole

Well-Known Member

This was the most recently finished knife, a bowie in 440c, about 12 in. long. I tried taking some pictures inside this time, didn't work too poorly, but I will continue to take pictures outside until I get the hang of it. I really liked this build, but the machine finish bugs me, because I kept getting worm lines from the belt splice. I also had to refinish the blade because the sheath was scratching it, as I was saying in the other post.