Ty Adams

KNIFE MAKER

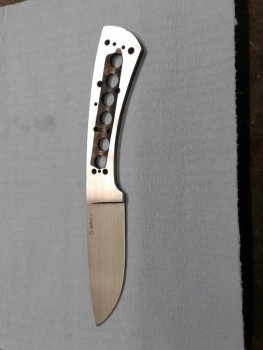

So I'm actually going to work on these today! I'll try to post pictures as I go, it will only be one knife with same process for both.

I start with a 120 grit ceramic belt and focus on fixing any small issues with blade. For me grinding is an art in constant correction, not getting the perfect grind. So not being afraid to only grind one area at a time has made my life easier.

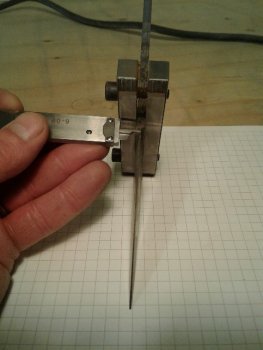

The plunge lines were not as centered as they could be. I set the calipers to the deepest plunge. Slowly I work the other side to match.

I start with a 120 grit ceramic belt and focus on fixing any small issues with blade. For me grinding is an art in constant correction, not getting the perfect grind. So not being afraid to only grind one area at a time has made my life easier.

The plunge lines were not as centered as they could be. I set the calipers to the deepest plunge. Slowly I work the other side to match.