Chris Railey

Well-Known Member

Those are cool. Are you going to add brass to the guard area?

I was thinking 416 stainless. I do have enough brass for that though. It is a thought.Those are cool. Are you going to add brass to the guard area?

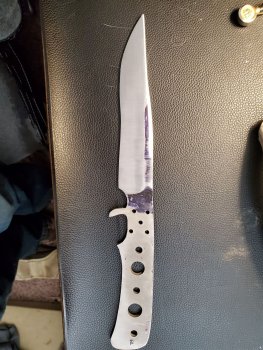

The blades are made out of AEB-L. I don't believe I can etch that. I'll check into it thoughI like the stainless idea it is different. I would like to see how that looks. Are you going to etch the blade at all? The contrast between the etched blade and the stainless guard might look good especially if your handle material is dark.

Did not know they were AEB-L nevermind on the etchThe blades are made out of AEB-L. I don't believe I can etch that. I'll check into it though

After the discussion in

After the discussion in

Thanks Randy. I was really nervous when I started the grind on this. I thought for sure I'd mess it up so bad I'd end trashing the knife.I’m no help. I haven’t ground a blade that long nor have I ground a swedge. My only advice would be to take your time. Know what you’re gonna do before you do it. I will say those blades are looking great!!

Thanks for the help John. I've been in a bit of a quandary as to what order to do these items in. I'll follow your advise and taper the tang next.Is the tang already tapered? If not, I would advise doing that before proceeding much further with the blade grinds.

My personal order of operations would be:

1. Taper tang

2. Grind main bevels to finished height (I prefer ful flat grind)

3. Hand sand blade to next to last grit (600-800)

4. Grind swedge/clip grind

5. Sand clip

6. Touch up blade if necessary

Thanks for the help John. I've been in a bit of a quandary as to what order to do these items in. I'll follow your advise and taper the tang next.

Your blades with a full flat grind are amazing. My original plan was to go about 3/4 to 7/8 up on mine; in other words height wise where I'm at now. I'll think about taking it full height. I do like the way the grind curves and I've matched it reasonably well (so far) on the other side. So I'll see how things go.

I do plan to use a separate bolster/guard. I've experimented on smaller knives with taking the tapered tang to just behind the bolster, or ever so slightly into it and then make certain it's flat through out.If your doing a separate bolster/guard from handle scales, you'll have to give some thought to where you're going to stop your taper. I chase mine out on the blade a little past the plunge line.

So you may have to tweak or even up your blade grinds, which is why I do them after the tang taper. The clip is last, even after hand sanding so the grind lines of the clip stay nice and sharp/crisp.

Fortunately for me, but maybe not for the wood, it's starting to cool off now. Enough so that I can work in my shop most afternoons.It is so hot where I am at the present, I just put wood in my 16 ft covered utility trailer and it kiln dries in no time.

Was one side waxed? If so it could be reacting to different exposure on each side. If so the rest should be OK.Fortunately for me, but maybe not for the wood, it's starting to cool off now. Enough so that I can work in my shop most afternoons.

I'm looking at getting a wood humidity tester. In the mean time I'll seal the end of the walnut and put it back with it's brethren and let it sit for another six months.

It was yes. It was the first piece I cut. The second piece seems OK.Was one side waxed? If so it could be reacting to different exposure on each side. If so the rest should be OK.