You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WTB 2x72 belt grinder

- Thread starter Tooln

- Start date

In that price range (or any range), my choice would be Reeder: https://reederproducts.com/shop/ols/products/rps-grinder 2hp with VFD for $1995price range is under 2k

Tooln

Well-Known Member

Do you own one? Thanks I'll check them out.In that price range (or any range), my choice would be Reeder: https://reederproducts.com/shop/ols/products/rps-grinder 2hp with VFD for $1995

Sean Jones

Well-Known Member

USAKnifemaker has a KMG that is just a bit over 2K. That's with a 2HP motor https://usaknifemaker.com/kmg-grinder-variable-speed.html

There is nothing wrong with the KMG linked to - it's variable speed and well built. I've talked with the Reeder folks a good bit at Blade show, examined the grinder, and have copied the tracking system to my homemade grinder. I've always built my own grinders with my first modeled after the original KMG grinder about 10 yrs ago.

I've read review by several folks I put a lot of confindiance in on the Reeder who really praised the Reeder. Their SGA is for sure the one I would purchase where I to buy a commercial unit.

With a budget of $2K there are several options out there that are good grinders.

I've read review by several folks I put a lot of confindiance in on the Reeder who really praised the Reeder. Their SGA is for sure the one I would purchase where I to buy a commercial unit.

With a budget of $2K there are several options out there that are good grinders.

Wayne Coe

Forum Owner - Moderator

Check out the video on the grinders page then look at the DVDs page for getting the DVD at www.WayneCoeArtistBlacksmith.com. Let me know if I can help you.

You can build Moe's Grinder for about $1,000,00 depending on your scrap pile. Angle iron and flat bar stock.

You can build Moe's Grinder for about $1,000,00 depending on your scrap pile. Angle iron and flat bar stock.

Last edited:

REK Knives

Well-Known Member

Reeder is amazing quality (I only own the surface grinder attachment fyi) and absolutely top notch customer service... But while I do like their grinder I find their tool arm to be leaving something to be desired imho. Other than that though it would also be my first choice probably

REK, what is it about the tool arms you don't like? Remember, I've never actually used a Reeder grinder at home, but just looking at the grinder I didn't see any issues. You're using one so know what you're talking about. Please share.I find their tool arm to be leaving something to be desired imho

I agree with you completely about the SGA, I think it's the best on the market.

REK Knives

Well-Known Member

Maybe I wasn't clear - I don't actually have a Reeder grinder, I ONLY have their SGAREK, what is it about the tool arms you don't like? Remember, I've never actually used a Reeder grinder at home, but just looking at the grinder I didn't see any issues. You're using one so know what you're talking about. Please share.

I agree with you completely about the SGA, I think it's the best on the market.

But regarding that... when you look at ones like Wilmont makes or NRT the Reeder one really seems to be lacking in the capability arena and is very basic. It works, but it doesn't excel imho.

Wilmont is personally my favorite because it can swing out of the way real quick (this is the tool work rest I actually have) for a platen or wheel change, or if I need to work the entire flat of the blade. It just saves time and is super convenient and can hit all the same positions that the RAT arm from NRT does.

Reeder work rest

Northridge Tool

Wilmont

Oh, I agree 100% the Reeder work rest is VERY basic design. It seems to work only when the grinder is vertical, but not horizontal. It's also fixed at the same location on the platen, and that might - or might not - be where you'd want it for a contact wheel.

Remember, any tool rest with an 1.5" tool arm will work just fine on the Reeder.

Remember, any tool rest with an 1.5" tool arm will work just fine on the Reeder.

MTBob

Well-Known Member

I've owned a Reeder grinder for over 2 years. It's a great machine that is built on a solid design and excellent workmanship. Don Reeder is the owner of the company and has applied years of machinist skills to the grinder design. His son Greg handles most of the shop activity and customer sales and support. It's a small shop that has grown a solid reputation & offers immediate customer support.

I have no complaints with this grinder (but, it's the only 2x72 I've owned).

Here are things I like:

- attention to detail & excellent machining of components

- tracking mechanism allows for both X & Y movement of the tracking wheel, this helps with tracking while running the belt in the reverse direction (a grinding technique used for blade sharpening)

- platen assembly is very adjustable, providing opportunity for creative setups

- belt tensioning is controlled with a spring NOT a gas actuator (gas actuators eventually fail due to grit in the piston)

- 2 arm design provides for lots of setup variations - in my opinion single arm designs are not desirable

- they sell a feature that flips the grinder and allows for horizontal belt position - something that I think is mandatory in a grinder (so I built my own bench assembly that flips the grinder - (in the end that cost me more than buying their design).

- and of course, having a variable speed drive is the only way to go. In my opinion don't buy a 2x72 if you can't afford a VFD!

Here are some things I don't like:

- the belt release handle is positioned poorly, especially for geezers with sore shoulders (a common design flaw on many grinders). I made an handle/arm extension that works better and allows for much faster belt changing.

- there is no spark guard to stop grinding material from flying off (I made one)

- I don't find this to be a problem, but something other people have said about the grinder - the frame assembly is made of aluminum. Some folks think this is inadequate and prefer a steel frame.

- the knife blade grinder attachment that they sell is useless (or at least I haven't figured out how to use it)

- though I don't have their grinder stand - to me it looks light weight and flimsy.

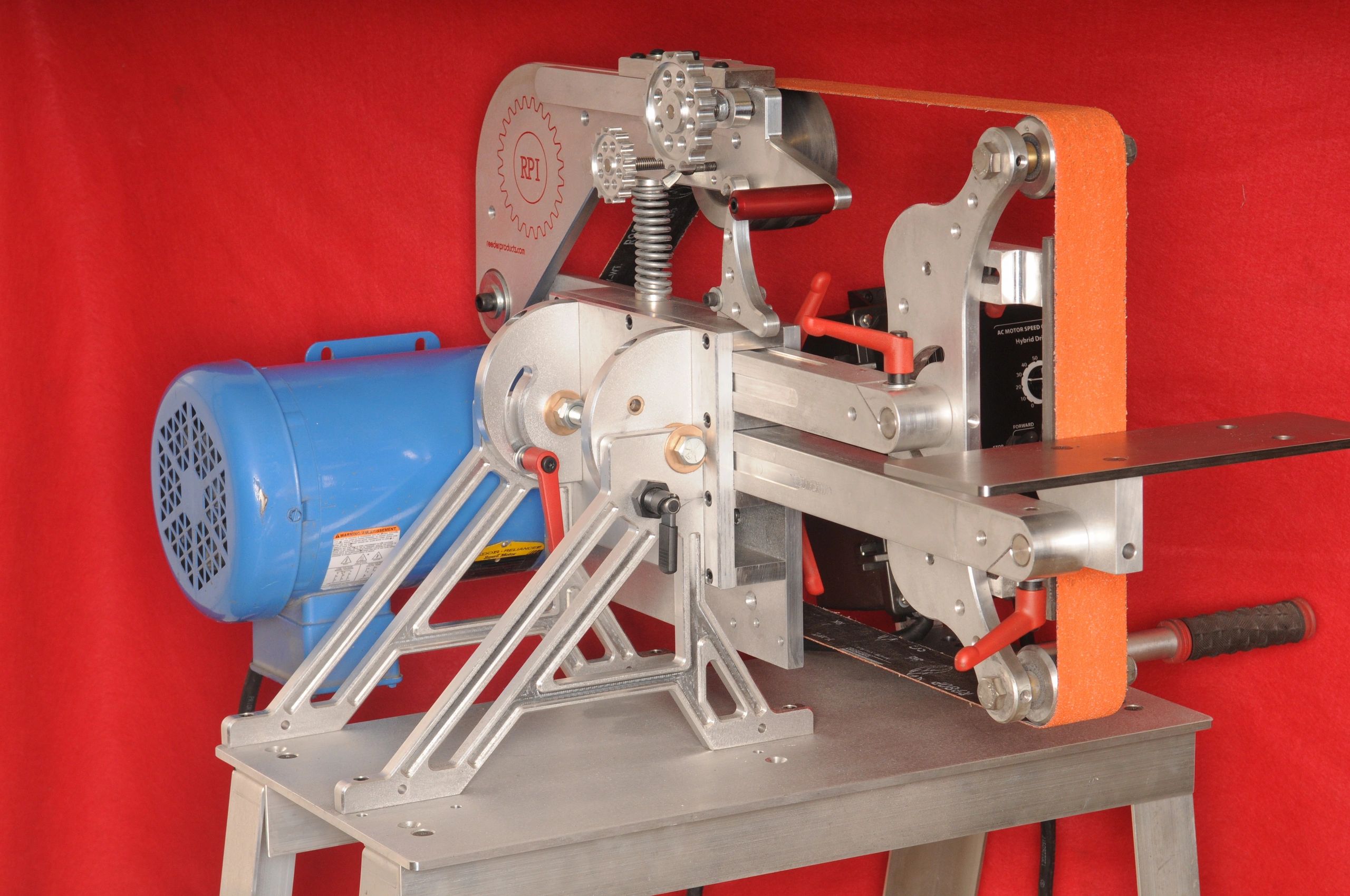

This photo gives and example of the platen setup flexibility & tension handle addition. I've added a spark deflector located just above the tracking wheel.

This is how I flip the grinder to the horizontal position. Note also that whole table moves up and down to adjust belt height. This is something that Reeder has added to their design options (though they flip the grinder differently).

I have no complaints with this grinder (but, it's the only 2x72 I've owned).

Here are things I like:

- attention to detail & excellent machining of components

- tracking mechanism allows for both X & Y movement of the tracking wheel, this helps with tracking while running the belt in the reverse direction (a grinding technique used for blade sharpening)

- platen assembly is very adjustable, providing opportunity for creative setups

- belt tensioning is controlled with a spring NOT a gas actuator (gas actuators eventually fail due to grit in the piston)

- 2 arm design provides for lots of setup variations - in my opinion single arm designs are not desirable

- they sell a feature that flips the grinder and allows for horizontal belt position - something that I think is mandatory in a grinder (so I built my own bench assembly that flips the grinder - (in the end that cost me more than buying their design).

- and of course, having a variable speed drive is the only way to go. In my opinion don't buy a 2x72 if you can't afford a VFD!

Here are some things I don't like:

- the belt release handle is positioned poorly, especially for geezers with sore shoulders (a common design flaw on many grinders). I made an handle/arm extension that works better and allows for much faster belt changing.

- there is no spark guard to stop grinding material from flying off (I made one)

- I don't find this to be a problem, but something other people have said about the grinder - the frame assembly is made of aluminum. Some folks think this is inadequate and prefer a steel frame.

- the knife blade grinder attachment that they sell is useless (or at least I haven't figured out how to use it)

- though I don't have their grinder stand - to me it looks light weight and flimsy.

This photo gives and example of the platen setup flexibility & tension handle addition. I've added a spark deflector located just above the tracking wheel.

This is how I flip the grinder to the horizontal position. Note also that whole table moves up and down to adjust belt height. This is something that Reeder has added to their design options (though they flip the grinder differently).

Gliden07

Well-Known Member

I have a Reeder, bought mine 5 years ago. LOVE IT! I bought the frame and bought wheels a motor and VFD. If you have a 3PH 1-1/2HP minimum or a VFD that will support a 1-1/2HP motor, I would buy the frame. If not the 2HP kit would be the way to go. Depending on your level of fabrication skills or your desire to build one I also liked the Polar Bear Forge GIB2 (Grinder in a Box 2). If like I said you have or can source a motor and VFD inexpensively you can get a quality grinder on the cheap!

PS 2HP is a better choice and 3HP would be even better but NOTHING SMALLER THAN 1-1/2HP

PS 2HP is a better choice and 3HP would be even better but NOTHING SMALLER THAN 1-1/2HP

Last edited:

Gliden07

Well-Known Member

What Reeder did you get?? I love mine! Congratulations don't think you're gonna regret it!I pulled the trigger yesterday and ordered a Reeder.

Tooln

Well-Known Member

RPS with VFD package.What Reeder did you get?? I love mine! Congratulations don't think you're gonna regret it!

CDHumiston

Well-Known Member

When you get the grinder please start a new thread to let us know how you like it! Pictures would also be awesome...RPS with VFD package.

CDHumiston

Well-Known Member

Just went to the Reeder site. Very Impressive. I love my Northridge Tools Grinder, but this one looks sweet as well...