C

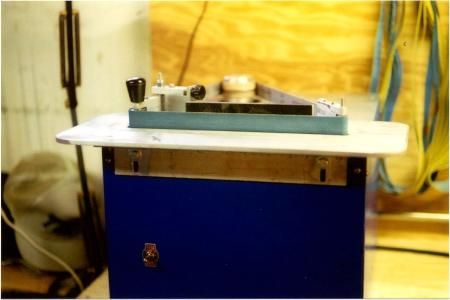

Complete180

Guest

Newly painted...

You betcha......its not complete without that. 2thumbs

now I have to find stickers for mine..

we need some KD stickers..

These have been posted before on other threads but I guess that I can post them again here:

It just dawned on me after the comments about stickers,,,, I need to forge a sculpture of Moe to put on my grinder. I'll get that done tomorrow.