You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's going on in your shop?

- Thread starter Justin Presson

- Start date

opaul

Well-Known Member

Awesome looking blade.Finished up this CuMai Hunter today. It looks great in person, but my picture taking skills are lacking today...

It has horn scales with copper pins to match the copper in the blade.

View attachment 82998View attachment 82999

Edwardshandmadeknives

Well-Known Member

Working on my very first integral! I want the bolster to look like a forged iron fitting, so it is “kinda” textured, I’ve got a bunch more I have to do to it but it’s kind of getting close. It’s a 10” blade, W2 from Aldo, with a pretty cool hamon. It shows up in the right light, with more polish and some etching it should pop. I don’t know what I’m going to do for the handle yet. I really want to do stacked birch bark. We’ll see

Attachments

Heikki

KNIFE MAKER

knuckle_heavy_knives

Member

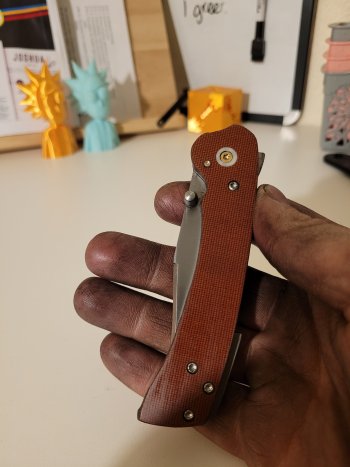

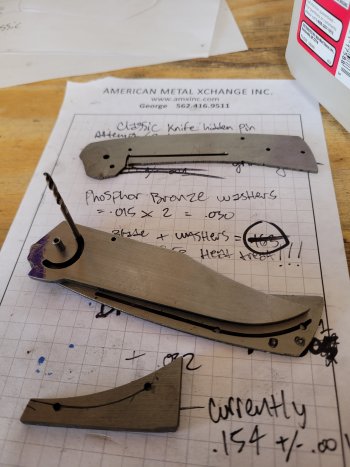

Finally getting back to folders, it's been quite some time, but I've been slowly finding more time to get in my shop. Work is busier than ever.

Worked on these designs over the past couple years and have finally started prototypes. Thanks for looking

Worked on these designs over the past couple years and have finally started prototypes. Thanks for looking

Attachments

Edwardshandmadeknives

Well-Known Member

Sean Jones

Well-Known Member

Nicely done!View attachment 83030

Getting my integral polished. I’m at 1000, the hamon is starting to pop out. Not only is this my first integral, it’s also my first intentional hamon. I’ve had them form spontaneously in the past, but this one I heat treated it specifically for the effect

Been busy lately with the stepson graduating High School, but I did get some stuff done!

S90V 3 5/8" blade, blue G10 guard and frame, Toxic Green G10 spacer/liners and SeaStrat G Carta handle.

Also did my first cable knife! I made my Pipe Vise into a Hardy tool (welded a long, 1" bolt to the bottom and ground the bolt to fit into the hardy hole) so I could get a better twist! Handle is Red AmeraGrip with black liners and some carbon fiber/red G10 burl material for the guard and frame.

My twisting pipe vise hardy tool:

I tried bottle openers a few weeks ago and they were predictably horrible, but I learned some stuff along the way!

I bought a cone mandrel, a punch from Kens Custom and a Guillotine tool:

I struggled with opening up the hole I punched on my anvil horn, so the cone mandrel helps get a more consistent round shape. The punch works better than my home made ones and the guillotine tool helps me isolate the material. I want to make a spring fuller next!

These were my next attempts at bottle openers! I used 1/2" Rebar. I used the guillotine tool to isolate the material and put the grooves into the handle and the punch and cone mandrels when working on the bottle opener portion. I also flattened the opposite end and curled it a bit on the horn of my anvil to help with opening soda/beer cans. My wife has her nails long, so I am always opening cans for her!

The one on the left I did without the guillotine tool and no dimples, but I got it done in about half the time as the one on the right! Going to try adding some twists to square bar, or do the rubix cube twist on the next bottle openers! I think I can do 2 or 3 bottle openers in an evening after work, so it's a fun little project!

S90V 3 5/8" blade, blue G10 guard and frame, Toxic Green G10 spacer/liners and SeaStrat G Carta handle.

Also did my first cable knife! I made my Pipe Vise into a Hardy tool (welded a long, 1" bolt to the bottom and ground the bolt to fit into the hardy hole) so I could get a better twist! Handle is Red AmeraGrip with black liners and some carbon fiber/red G10 burl material for the guard and frame.

My twisting pipe vise hardy tool:

I tried bottle openers a few weeks ago and they were predictably horrible, but I learned some stuff along the way!

I bought a cone mandrel, a punch from Kens Custom and a Guillotine tool:

I struggled with opening up the hole I punched on my anvil horn, so the cone mandrel helps get a more consistent round shape. The punch works better than my home made ones and the guillotine tool helps me isolate the material. I want to make a spring fuller next!

These were my next attempts at bottle openers! I used 1/2" Rebar. I used the guillotine tool to isolate the material and put the grooves into the handle and the punch and cone mandrels when working on the bottle opener portion. I also flattened the opposite end and curled it a bit on the horn of my anvil to help with opening soda/beer cans. My wife has her nails long, so I am always opening cans for her!

The one on the left I did without the guillotine tool and no dimples, but I got it done in about half the time as the one on the right! Going to try adding some twists to square bar, or do the rubix cube twist on the next bottle openers! I think I can do 2 or 3 bottle openers in an evening after work, so it's a fun little project!

opaul

Well-Known Member

I wish I had the skills and patience to do that. Top notch work!Next batch of orders cut out and profiled and in the heat treat oven. Got a 2 blade trapper, Dino, medium trapper, and 3 blade stockman

Sent from my SM-G981V using Tapatalk

Edwardshandmadeknives

Well-Known Member

Started my first dagger! 1/8" 80CRV2 steel, going to have 4 layers of Carbon Fiber Marble for the guard (with a red liner in the middle), black AmeraGrip for the handle and black G10 for the frame and red liners.

Got the Cable knife fully done.

Kryptek compliments the cable pattern nicely!

And the 3 5/8" S90V Bird and Trout with Blue g10 guard and frame, toxic green G10 liners and SeaStrat G Carta for the handle is all done as well!

Got the Cable knife fully done.

Kryptek compliments the cable pattern nicely!

And the 3 5/8" S90V Bird and Trout with Blue g10 guard and frame, toxic green G10 liners and SeaStrat G Carta for the handle is all done as well!

knuckle_heavy_knives

Member

Edwardshandmadeknives

Well-Known Member

Finally finished this beast of a gyuto! W2, integral, with some quilted rainbow Siamese Rosewood from Greenberg Woods. I “s” ground this on my 36” platen, then used my 8” contact wheel on the lower part of the s, so there is a tighter radius along the edge. I really like the way it looks, but it was really a pain to grind. This is also a takedown, composed of only three pieces. The blade, the wood, and a 304 stainless Allen socket nut I made to hold it all together. I buy stainless Allen bolts and turn the threads off on the lathe and then drill and tap them to make the nuts. First hamon and first integral, and I’m pretty happy with it.

Edwardshandmadeknives

Well-Known Member

Thank ya sir! Trust me, if I can do it, YOU can do it!ha just takes some time and lots of screw-ups!ha Here's the 2 blade trapper I finished for an order todayI wish I had the skills and patience to do that. Top notch work!

Sent from my SM-G981V using Tapatalk

Got the Dagger done! The right side of the tip looks funky, but it's from the pic itself. The black AmeraGrip looks really cool, almost like a tight carbon fiber look to it!

Did the wider S90V drop point with spine jimping and buffed the AmeraGrip at the customers request. It actually buffed nice on the fiberglass portion and the rubber stayed nice and grippy!

Did the wider S90V drop point with spine jimping and buffed the AmeraGrip at the customers request. It actually buffed nice on the fiberglass portion and the rubber stayed nice and grippy!