Josh Dabney

Moderator

Just thought I'd throw up a post in the hopes of getting some comments/critisism on the knives I've recently completed. All comments are welcomed guys so let me have it !

Here's a shot of my #7 knife. It's shadow pattern slip joint in carmel micarta. ATS-34 zulu pattern from GLWJ. The function is great on this one and flush in all three positions. The blade does however lay to one side in the closed position Overall I'm pretty happy with it for a first attempt at a slippie.

Overall I'm pretty happy with it for a first attempt at a slippie.

#8 This knife was designed and built to the customers request for a early to mid-19th century working blade.

6 1/2" 1095 spear point with false clip. This blade is extra stout all the way to the tip, also at the customers request but she's still shaving sharp. Curly maple scales, copper and mild steel rivets. The copper washers are recessed into the wood (read squeezed). I did put a few axtra dings in the maple figuring out the process to recess the washers but I've got it figured out now for future projects. I also did one more coat of tru-oil after the pics were taken that really brought out the chatoyance of the curl. Customer is making his own sheath for this one.

but I've got it figured out now for future projects. I also did one more coat of tru-oil after the pics were taken that really brought out the chatoyance of the curl. Customer is making his own sheath for this one.

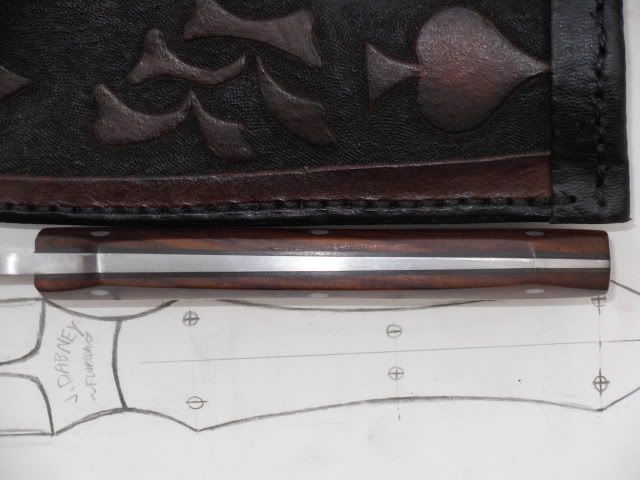

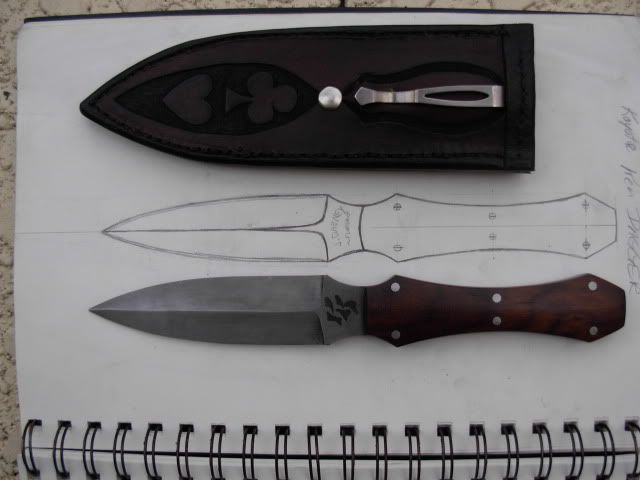

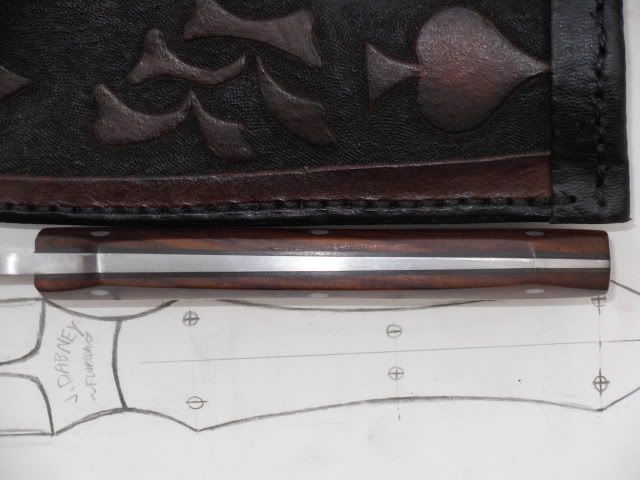

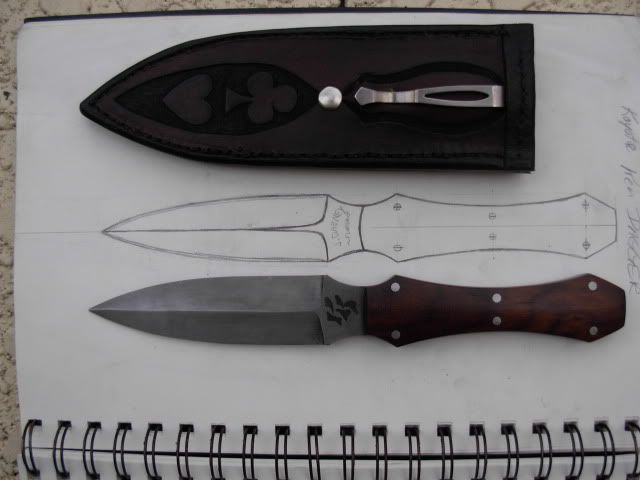

#9 Also a customer spec knife.

3 3/4" 1095 Boot Dagger. 8 1/1" OAL. Blackwalnut with black liners and mild steel pins. Tru-Oil finish.

Sheath tooled with customers KK logo (his initials) and ricasso also etched with KK logo.

Again all comments and critiques good or bad are welcomed and greatly appreciated

Thanks guys ! Josh

Here's a shot of my #7 knife. It's shadow pattern slip joint in carmel micarta. ATS-34 zulu pattern from GLWJ. The function is great on this one and flush in all three positions. The blade does however lay to one side in the closed position

#8 This knife was designed and built to the customers request for a early to mid-19th century working blade.

6 1/2" 1095 spear point with false clip. This blade is extra stout all the way to the tip, also at the customers request but she's still shaving sharp. Curly maple scales, copper and mild steel rivets. The copper washers are recessed into the wood (read squeezed). I did put a few axtra dings in the maple figuring out the process to recess the washers

#9 Also a customer spec knife.

3 3/4" 1095 Boot Dagger. 8 1/1" OAL. Blackwalnut with black liners and mild steel pins. Tru-Oil finish.

Sheath tooled with customers KK logo (his initials) and ricasso also etched with KK logo.

Again all comments and critiques good or bad are welcomed and greatly appreciated

Thanks guys ! Josh