You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Well This Is Weird

- Thread starter Randy Lucius

- Start date

bladegrinder

Well-Known Member

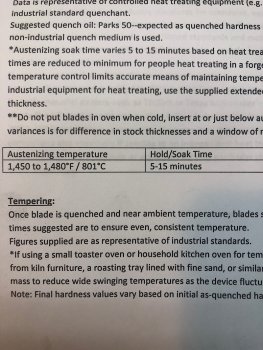

Just looks like decarb, I've never used 1084 but why the 15 min. soak?

Randy Lucius

Well-Known Member

J. Doyle

Dealer - Purveyor

Have you verified your oven temps? I've been hearing a LOT of makers finding out lately their ovens were off by a fair bit. That'd definitely be something I'd check asap if you haven't.

I think ovens are great but you have to know if the temps that are displaying are accurate.

I think ovens are great but you have to know if the temps that are displaying are accurate.

Randy Lucius

Well-Known Member

It’s a brand new Evenheat oven I got for Christmas. I don’t currently have a way of verifying temps.Have you verified your oven temps? I've been hearing a LOT of makers finding out lately their ovens were off by a fair bit. That'd definitely be something I'd check asap if you haven't.

I think ovens are great but you have to know if the temps that are displaying are accurate.

J. Doyle

Dealer - Purveyor

Well.....I'd figure something out.

You could verify with a secondary independent thermocouple.

Or you could buy some tempilstick test sticks that melt at various specified temps.

Or I believe table salt melts fairly consistently at 1470 F.

I certainly wouldn't want to assume its accurate because its a brand new name brand.......just sayin'.

I've got a good friend that just finally tested his evenheat after a couple years of assuming it was good and found out it was off by over 60 degrees.

You could verify with a secondary independent thermocouple.

Or you could buy some tempilstick test sticks that melt at various specified temps.

Or I believe table salt melts fairly consistently at 1470 F.

I certainly wouldn't want to assume its accurate because its a brand new name brand.......just sayin'.

I've got a good friend that just finally tested his evenheat after a couple years of assuming it was good and found out it was off by over 60 degrees.

tkroenlein

Well-Known Member

Looks like decarb to me as well. The look can vary based on quenchant and how much it's decarbed.

I saw your vid on IG. I think you're supposed to make the steel lemon yellow and get a gigantic fireball when your quench is good. At least that's what they do on TV.

I saw your vid on IG. I think you're supposed to make the steel lemon yellow and get a gigantic fireball when your quench is good. At least that's what they do on TV.

You're funny! I've often thought about just how much over temp lots of those blades are when quenched on FiF. Even under those bright lights they are really bright orange when they quench. Only a few times does anybody bring a magnet to test for quench.steel lemon yellow and get a gigantic fireball when your quench is good

Randy, to prevent scale buildup on high carbon I usually sprinkle borax (roach powder) over the blade as gently heating to melt powder. This forms a thin "glass" glaze over the blade to prevent scale buildup. After quench any that's left washes off easy with hot water.

My even heat has always been around 50 degrees off, give or take, right out of the box.

I picked up a K type thermocouple and PID controller all under $100.

Callinrated the controller to "0" in a slurry of ice and water.

Stuck the thermocouple through the front brick of my oven.

Then I either go by the temperature on the PID or compensate the temps in my head.

Other than that... Looks like decarb to me as well.

I picked up a K type thermocouple and PID controller all under $100.

Callinrated the controller to "0" in a slurry of ice and water.

Stuck the thermocouple through the front brick of my oven.

Then I either go by the temperature on the PID or compensate the temps in my head.

Other than that... Looks like decarb to me as well.

Kevin R. Cashen

Super Moderator

Just looks like decarb, I've never used 1084 but why the 15 min. soak?

15 minutes is a bit too long. The sheet mentions 5-15, they are probably using a blanket time frame for multiple alloys, I would keep it closer to the 5 minute mark for 10XX series. Whenever you see a temp or time range, the lowest numbers you can get away with are the best options. But that doesn't look like what I am used to when I see decarb. I'm thinking more along the lines of some sort of oxidation effect or a possible issue in the steel itself. It is very hard to say from just a picture. If it is decarb, it is a very odd, localized, version, perhaps incipient, before it gets too out of control.

Randy Lucius

Well-Known Member

Thanks Kevin. Very good info. I’ll adjust the time and temp on the next one. I’ll finish grinding the blade this afternoon and do a hardness test.15 minutes is a bit too long. The sheet mentions 5-15, they are probably using a blanket time frame for multiple alloys, I would keep it closer to the 5 minute mark for 10XX series. Whenever you see a temp or time range, the lowest numbers you can get away with are the best options. But that doesn't look like what I am used to when I see decarb. I'm thinking more along the lines of some sort of oxidation effect or a possible issue in the steel itself. It is very hard to say from just a picture. If it is decarb, it is a very odd, localized, version, perhaps incipient, before it gets too out of control.

Kevin R. Cashen

Super Moderator

If you clean the black off, without much stock removal, until the blade is just clean and shiny again, you may be able to see the spots still and it could tell you more. If you then give it a quick dip in ferric chloride, decarb will then make itself know much more clearly in the form of silvery, unetched spots. If the specks you have now turn dark, or take on a pitted look, you have a deeper issue in the steel itself.

Randy Lucius

Well-Known Member

Thanks again Kevin. I’ll follow your recommendations and see where it leads.If you clean the black off, without much stock removal, until the blade is just clean and shiny again, you may be able to see the spots still and it could tell you more. If you then give it a quick dip in ferric chloride, decarb will then make itself know much more clearly in the form of silvery, unetched spots. If the specks you have now turn dark, or take on a pitted look, you have a deeper issue in the steel itself.

Randy Lucius

Well-Known Member

Cleaned up the decarb and ran a hardness test. 60 Rockwell C. Right on the money according to the heat treat sheet I have. Can I assume this will make a decent knife?

Randy Lucius

Well-Known Member

Bruce McLeish

Well-Known Member

The whole thing looks defective to me. You should immediately send it to me so I can look closer at it. Don't worry, I'll be very fair in my assessment, but you prolly can guess the outcome of my tests.!

Randy Lucius

Well-Known Member

Hey ol’ friend!! Hope you are doing well.The whole thing looks defective to me. You should immediately send it to me so I can look closer at it. Don't worry, I'll be very fair in my assessment, but you prolly can guess the outcome of my tests.!

Bruce McLeish

Well-Known Member

Very well, thank you. Got my newly sharpened files, got the kiln working for ht, things are just terrific. Hope all is good for my favorite southerner and family.Hey ol’ friend!! Hope you are doing well.

tkroenlein

Well-Known Member

Randy Lucius

Well-Known Member

Just the lighting. It’s all very uniform in appearance. Heading back out to the shop to give it an etch.Is this a reflection or a difference in the coloration of the steel? Did you etch it like Kevin suggested?View attachment 71721