This is a placeholder thread for information and assembly of the U Weld Grinder Kit.

Overview: the U Weld grinder kit will be a full 2x72” grinder that is welded/assembled by the customer.

No Price or release date has been set. (but soon)

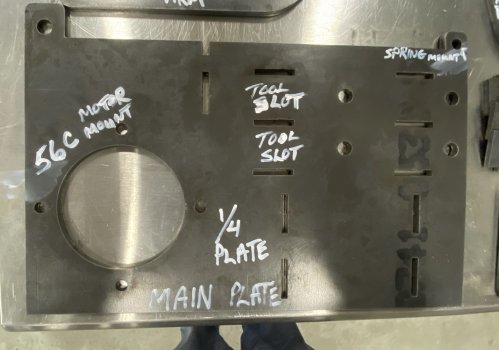

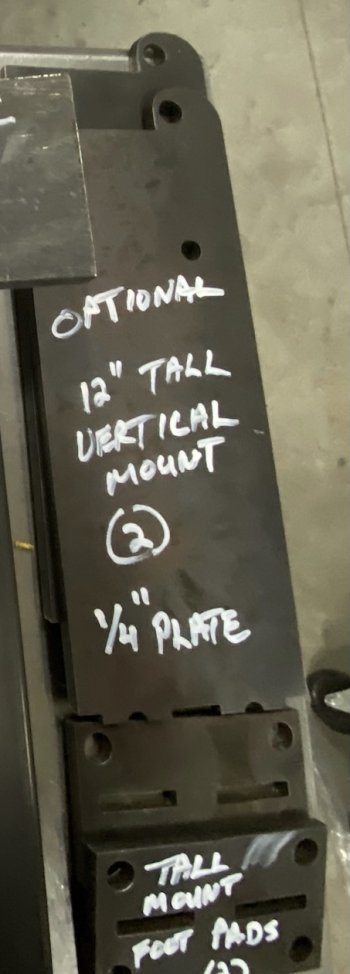

Having said that, the idea here is to put out a reasonably priced grinder kit using parts we cut in house using our CNC Plasma table.

Tools required:

I suggest at minimum a 1.5hp variable speed motor. I usually put a 2hp or 3hp motor on shop grinders.

We are working on getting set up to sell motors and VFD speed controllers but that will take some time.

The kit will ship in a flat pack and assembles using tab and slot that the customer will weld together using simple button welds.

The grinder is direct drive design and will rotate 90 degrees for horizontal grinding.

The following posts will be edited as I develop the instructions for the build process.

Overview: the U Weld grinder kit will be a full 2x72” grinder that is welded/assembled by the customer.

No Price or release date has been set. (but soon)

Having said that, the idea here is to put out a reasonably priced grinder kit using parts we cut in house using our CNC Plasma table.

Tools required:

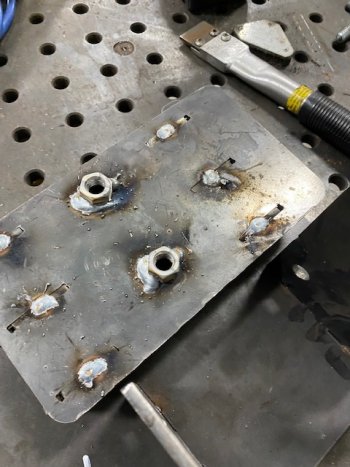

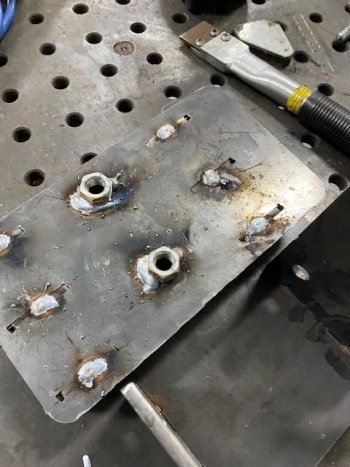

- A welder. Actual welding time will be less than 30 minutes by a beginner welder. The tab and slot design will make assembly easy.

- 2 adjustable wrenches to attach and tighten wheels and some fasteners

- a hand drill and 1/4” drill bit. There is one hole to drill after assembly.

I suggest at minimum a 1.5hp variable speed motor. I usually put a 2hp or 3hp motor on shop grinders.

We are working on getting set up to sell motors and VFD speed controllers but that will take some time.

The kit will ship in a flat pack and assembles using tab and slot that the customer will weld together using simple button welds.

The grinder is direct drive design and will rotate 90 degrees for horizontal grinding.

The following posts will be edited as I develop the instructions for the build process.

Last edited: