Kevin Zito

KNIFE MAKER

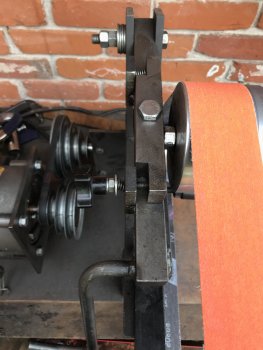

I need some help. So my flat platen and the 8 inch contact wheel run perfectly. However, I run into issues when I put on the 12 in. I want to the belt to hand off the left hand side of the wheel say 1/8” to 1/4”. I can get the belt to ride in that spot to say my life. It will ride perfectly on the right hand side. I have tried the following with no luck:

The bearings that I installed were shot so I brought the wheel to a machine shop and had them replace the bearings.

I have tried a ton of different belts with the same result.

Please help me fix this.... it’s driving me crazy. Thank you all!

The bearings that I installed were shot so I brought the wheel to a machine shop and had them replace the bearings.

I have tried a ton of different belts with the same result.

Please help me fix this.... it’s driving me crazy. Thank you all!