Tooln

Well-Known Member

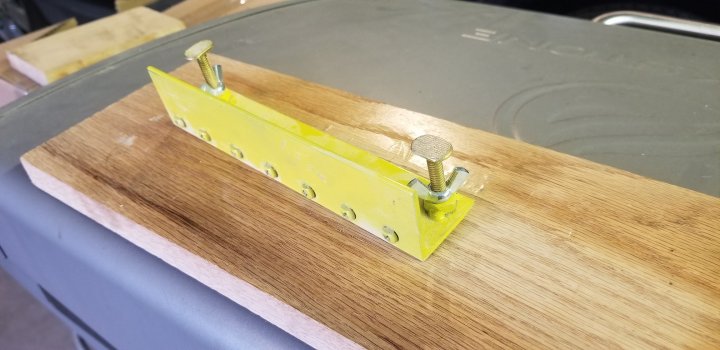

I've been working on my first knife. It's 1095 & not going to be anything fancy. I plan on an oak handle and a layer of kydex. Since this is all new and my space is limited, I'm making a firebrick forge. I have an old toaster oven for tempering that I'm putting a temp control on so I can run a PID loop. So far I've made myself a jig for grinding & a magnetic holder. I've just a little more work into the profile. Then once my stuff gets here for the forge and controller put them together and away I go. Any suggestions or criticism is welcome.