please note: I moved a few of the following posts from the shop thread and merged them with this thread. Some may seem out of order. They are but I wanted all this in one threadand the software won’t let me straighten them out exactly.

This thread will be about forging Damascus titanium. Post any comments you like. If you have done this, speak up. Forging Ti isn’t well documented and I thought I would see how it works and share my experiments.

Working on making some Titanium Mokume.

Never done it so made up some 2x2" square stacks.

Alternating between 3 kinds of Ti: 6al, CP (pure) and 6242.

Prepped like steel damascus.

Stacked and Tig welded around the entire edge.

The Tig welding was way faster and easier than anticipated.

I'll heat these to dull/bright red and squeeze in the press.

Once it's welded, I hit one test black with the hammer and the other with a ladder die.

I'll post pics when I get that done - win or fail.

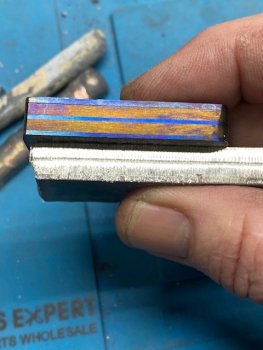

TIG welded edge. No filler added. Ti puddles nicely and can be moved around easily with a TIG torch. I would guess that a fine tip oxy/acetylene torch would work also.

This thread will be about forging Damascus titanium. Post any comments you like. If you have done this, speak up. Forging Ti isn’t well documented and I thought I would see how it works and share my experiments.

Working on making some Titanium Mokume.

Never done it so made up some 2x2" square stacks.

Alternating between 3 kinds of Ti: 6al, CP (pure) and 6242.

Prepped like steel damascus.

Stacked and Tig welded around the entire edge.

The Tig welding was way faster and easier than anticipated.

I'll heat these to dull/bright red and squeeze in the press.

Once it's welded, I hit one test black with the hammer and the other with a ladder die.

I'll post pics when I get that done - win or fail.

TIG welded edge. No filler added. Ti puddles nicely and can be moved around easily with a TIG torch. I would guess that a fine tip oxy/acetylene torch would work also.

Last edited: