papi

Well-Known Member

Hey guys,

i finally got around to do this, and hoping i'm in the right section, here's the first batch of pics.

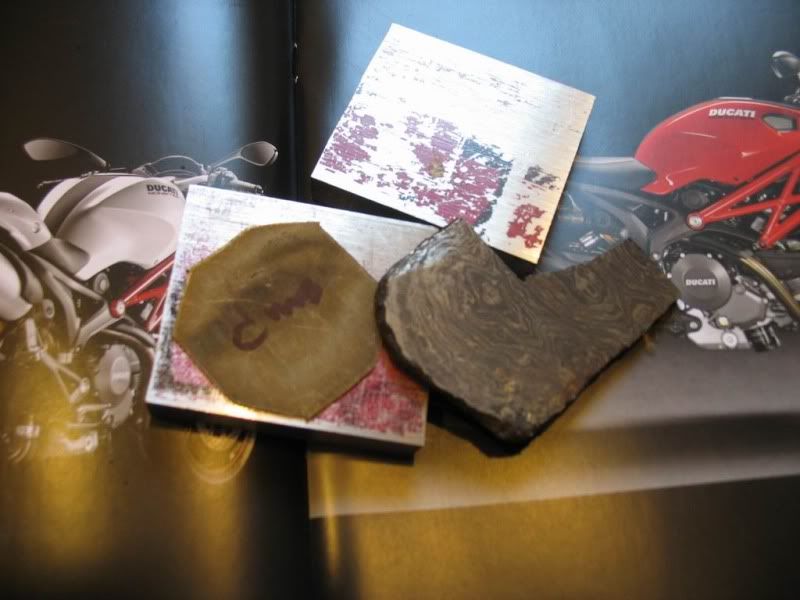

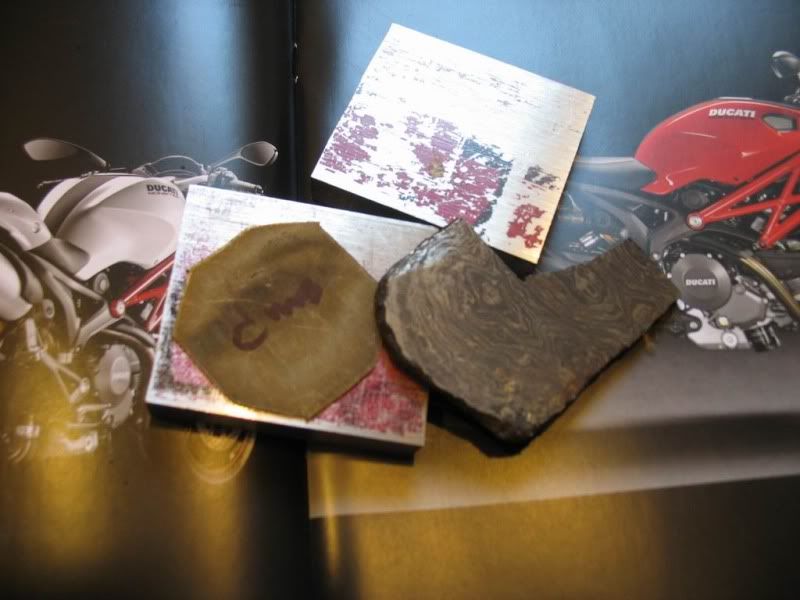

This is how it starts - just a bunch of stock - some titanium, damascus... there are some pieces still missing, but i will add them as i go along.

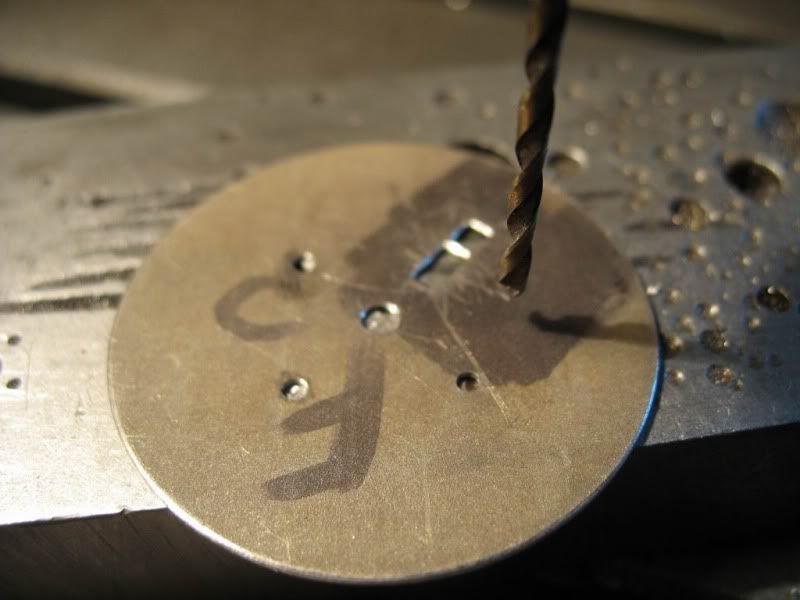

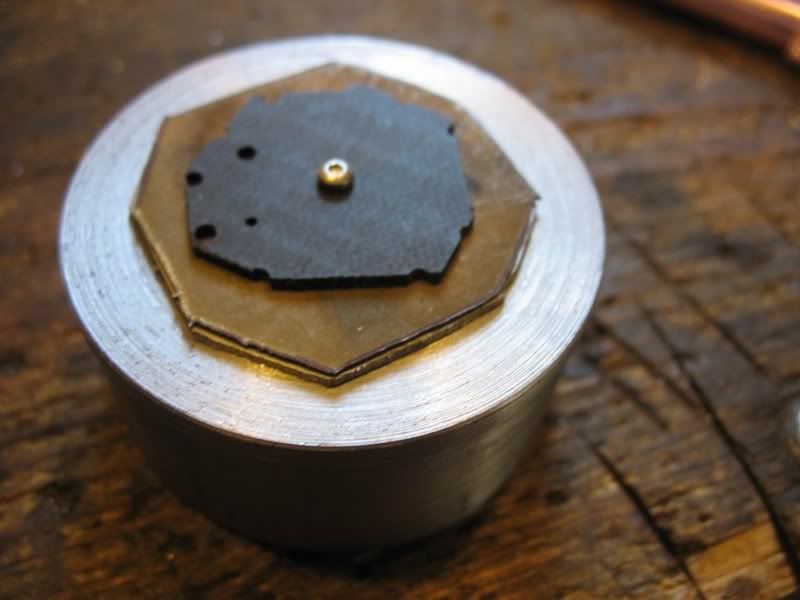

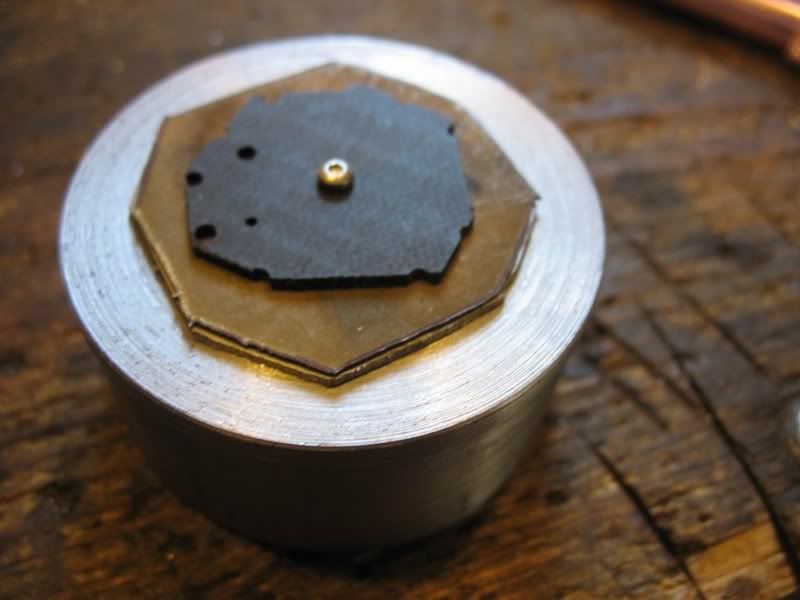

fitting the dial material to a fixture - here, the fixture is centered with the spindle of my mini mill

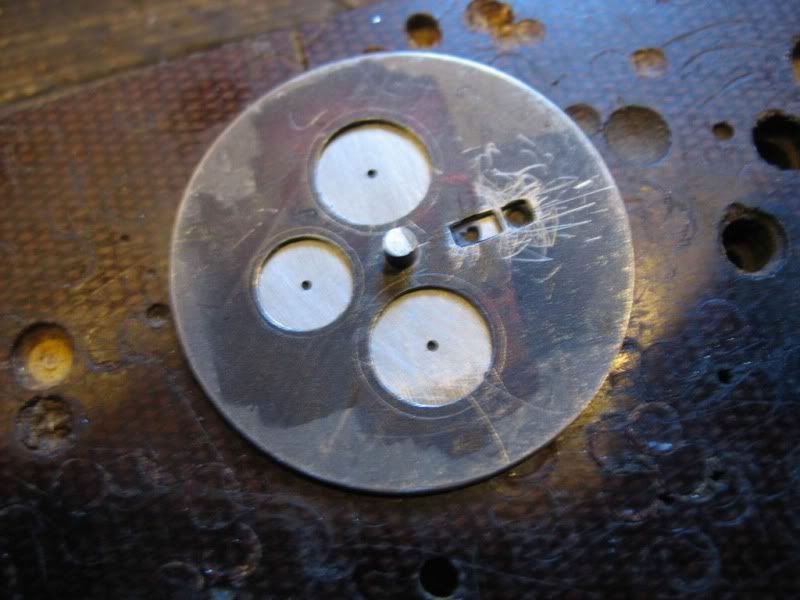

and the dial material superglued to the fixture, with the counter holes measured and drilled

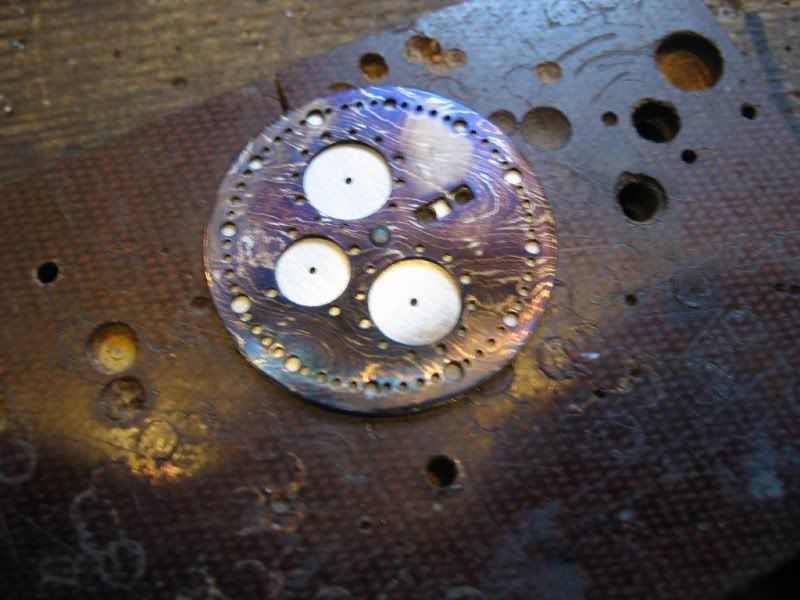

now i transfer the holes to a lower layer (this will be a sandwich dial), which will be a piece of 0.015" titanium

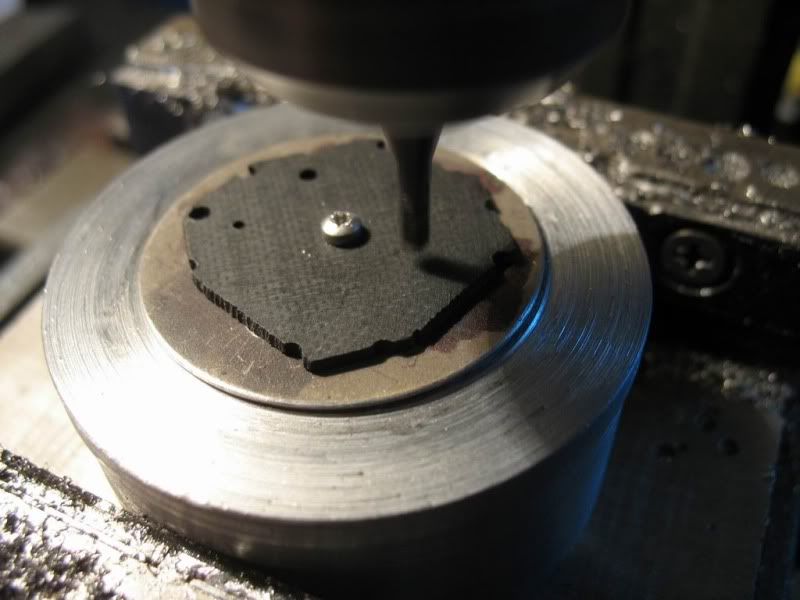

glue those two plates together, and glue them onto the fixture and secure them with a screw and a piece of G10. That helps to distribute pressure, so the glue doesn't let go when i'm turning this from that crazy shape into a nice round circle.

TO BE CONTINUED...

i finally got around to do this, and hoping i'm in the right section, here's the first batch of pics.

This is how it starts - just a bunch of stock - some titanium, damascus... there are some pieces still missing, but i will add them as i go along.

fitting the dial material to a fixture - here, the fixture is centered with the spindle of my mini mill

and the dial material superglued to the fixture, with the counter holes measured and drilled

now i transfer the holes to a lower layer (this will be a sandwich dial), which will be a piece of 0.015" titanium

glue those two plates together, and glue them onto the fixture and secure them with a screw and a piece of G10. That helps to distribute pressure, so the glue doesn't let go when i'm turning this from that crazy shape into a nice round circle.

TO BE CONTINUED...