REK Knives

Well-Known Member

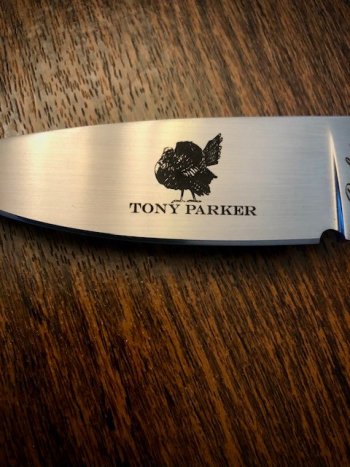

@Chris Railey suggested we start a thread for all things related to lasers and I think it's a great idea!

Any questions comments please post below.

Note, this thread is for all things laser related... Fiber, co2, diode, etc

Here's my set up (50w fiber) with ventilation

Any questions comments please post below.

Note, this thread is for all things laser related... Fiber, co2, diode, etc

Here's my set up (50w fiber) with ventilation

Last edited: