You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Slimline Trapper

- Thread starter Craig

- Start date

rhinoknives

Well-Known Member

Calvin Robinson

Moderator Christian Forum

I like everything about it!

Travis Fry

Well-Known Member

I literally got chills!

T.A. DAVISON

Well-Known Member

That is a beauty - nice job. - :thumbup:

TA

TA

Garry Odgers

Well-Known Member

Excellent piece, like it

McClellan Made Blades

Well-Known Member

When you say intergal bolsters and liners do you mean they were machined from one piece of steel? That is an idea I wanted to try, I'm just glad someone that KNEW what they were doing tried it first! I am no machinist!!! Great work, how difficult was it. Or how much easier was it? Thanks, Rex

Rex, Thanks!

Yes they were milled out of a solid bar. I am no machinist at all either. I had a lot of help from machinist and other knife makers that showed me how to do it. I like it better than attaching bolsters by welding or soldering. It takes a little longer but works better for me in the end.

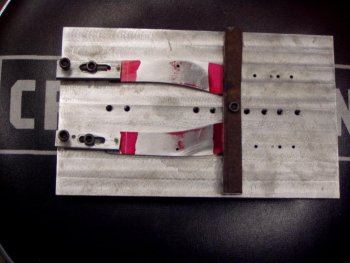

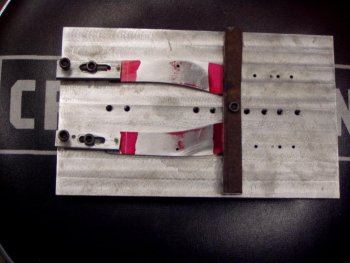

I made up a plate with a cleat on the back to hold in my vice and square all edges. I drilled some pin holes inline and drilled and tapped some holes for hold down clamps. I scribe where the bolsters will be, line it up with a machinist square and clamp it down. When I get to where the cap will be I loosen the clamps and lineup that scribe mark and finish milling to the line.

Here is a photo of what I use on my mill drill.

Craig

Yes they were milled out of a solid bar. I am no machinist at all either. I had a lot of help from machinist and other knife makers that showed me how to do it. I like it better than attaching bolsters by welding or soldering. It takes a little longer but works better for me in the end.

I made up a plate with a cleat on the back to hold in my vice and square all edges. I drilled some pin holes inline and drilled and tapped some holes for hold down clamps. I scribe where the bolsters will be, line it up with a machinist square and clamp it down. When I get to where the cap will be I loosen the clamps and lineup that scribe mark and finish milling to the line.

Here is a photo of what I use on my mill drill.

Craig

Bruce Bump

Forum Owner-Moderator

Super slimline trapper. I like the styling allot. Looks like the blade centers well, thats something I worry about.

McClellan Made Blades

Well-Known Member

Rex, Thanks!

Yes they were milled out of a solid bar. I am no machinist at all either. I had a lot of help from machinist and other knife makers that showed me how to do it. I like it better than attaching bolsters by welding or soldering. It takes a little longer but works better for me in the end.

I made up a plate with a cleat on the back to hold in my vice and square all edges. I drilled some pin holes inline and drilled and tapped some holes for hold down clamps. I scribe where the bolsters will be, line it up with a machinist square and clamp it down. When I get to where the cap will be I loosen the clamps and lineup that scribe mark and finish milling to the line.

Here is a photo of what I use on my mill drill.

View attachment 31912

Craig

Craig,

That is a SWEET little jig you have there Bud, I don't know where I got the idea from, I'm sure I picked it up somewhere. I was curious about the weight and "feel" of it, It should be a stronger design. The waste bothers me a little bit, but in the end it's worth it.

Where did you get the idea for this type of construction? I was thinking about trying Aluminium, I think the best material for this type of build would be Titanium, just think of the possibile with annodizing and on a fixed blade it would leave an incredible amount of room for engraving. Not having a mill any more, I come up with a lot of "needs" for one now. Having good equipment is a luxury, I learned that having even the best equipment doesn't mean a hill of beans if you don't know how to run the eqipment properly! I had a HF mini mill, good mills are a bit much, too much for me to spend for the next couple of years, unless I get to making a lot more knives and saving that money to buy one. But, I'd probaly buy a Hydraulic Press first.

Im planning on getting one like this started soon, I haven't gotten into making folders yet and the first time I did get started on one, I got so frustrated trying pick up the screws, trying to use my big hands for something that wasn't meant for them to do, I finially realized that I wasn't having fun, so I set it a side for a later date.

I have planned on making folders ever since I started making knives, I think I'm ready to give it another go, and take my time, not rush it and try to make it FUN!!!

I'll say it again, this knife is a BEAUTY!!!! Thanks for sharing, Rex

One thing I've noticed about equipment in the South, The North has, a lot more of this type of equipment, I rarely ever see any heavy duty machining type equipment. I've seen a couple of machines I would have loved to have gotten. One was a Bridgeport knee mill, the other was a surface grinder, for $600!!!! At the time, I didn't know anything about surface grinder, so I didn't realize what a deal that was! It was a bigger one, I can't remember for sure, but I think the size of it was 12 x 8 or something like that.

I've got every person I know watching for anvils, there simply aren't that many around here, I do recall during the Civil War, when the North would find an anvil the would break the horn off of it. That could be a reason, that and the fact that the North has been in business longer than we have and that there is so much more industry up that way.

I was thinking about using Nickle Silver for the liners and bolsters, it would be pretty easy to work with, I would have to question the strength of it though, BUT(!) it would look incredible engraved.

How thick did you leave the liners. I was thinking 1/8 or maybe less, 1/8 would leave even more room for engraving.

Did you had any steps that were more difficult? Any problem areas that I should be aware of? Also, what kind of bushings/washers did you use?

Last edited:

Rex, a number of makers have been building slip joints like this for a long time. I am just so slow that it took me a while to get things working for me. The book “How T. Make Multi-blade Folding Knives” has several photos of similar type set ups for milling the liners. I think there are as many ways to set up and mill the liners as there are knife makers.

My plate is made of mild steel ½ in thick and the cleat on the back is ½ inch thick 3 inches wide and ¾ the length of the plate. That is what I had on hand and I think it works fine. I put the cleat on because my vice will not open wide enough to hold the plate, this way I just clamp on the cleat.

I mill the liners to about .040 - .050. Weight wise they are the same as one with welded or soldered bolsters. As long as you put the plate in the vice square to the spindle and in line with the x axis it is a very repeatable process. If you want to try when you get a mill again just cut out some mild steel liners and practice milling them to make sure the bolsters line up before using your liner material.

The bushings are a bronze alloy. 630 is what the makers I spoke with recommended. Some of the knife supply shops have some bushings that are phosphor bronze. You could also have some made at a local machine shop. I do a relief cut inside the liners and do not use any washers.

My plate is made of mild steel ½ in thick and the cleat on the back is ½ inch thick 3 inches wide and ¾ the length of the plate. That is what I had on hand and I think it works fine. I put the cleat on because my vice will not open wide enough to hold the plate, this way I just clamp on the cleat.

I mill the liners to about .040 - .050. Weight wise they are the same as one with welded or soldered bolsters. As long as you put the plate in the vice square to the spindle and in line with the x axis it is a very repeatable process. If you want to try when you get a mill again just cut out some mild steel liners and practice milling them to make sure the bolsters line up before using your liner material.

The bushings are a bronze alloy. 630 is what the makers I spoke with recommended. Some of the knife supply shops have some bushings that are phosphor bronze. You could also have some made at a local machine shop. I do a relief cut inside the liners and do not use any washers.