You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shop Tip of the Day - Add yours here

- Thread starter BossDog

- Start date

Mike Martinez

Well-Known Member

Aus, cool idea... mind shooting an action shot?

Ausbrooks

KNIFE MAKER

Mike, here ya go- first one is flat grinding (as much as can with one hand!) and second pic shows blade in jig. I put electrical tape down during final polishing to prevent scratching when flip blade from side to side. Kind of a poor man's surface grinder, I like to think...:1:

A.W.Stovall

Well-Known Member

Thats a great Idea Ausbrooks can you show pics of it without the knife blade if you don't mind .

Anthony

Anthony

Ausbrooks

KNIFE MAKER

Anthony, here ya go. As pic shows, aluminum is 7" x 2.75" x .5" and dowel pins are .25". The rare earth magnet in middle is a Magcraft .5 dia. x .375 thick- if you put 2 of them in alum. you probably would not need the dowel pins to keep blade from moving. The slots are random to add as much surface area as possible.

Ronald P. Rochon

Well-Known Member

Thanks for sharing Ausbrooks. Very smart jig! Ron.

A.W.Stovall

Well-Known Member

Thanks for the pic gonna build one soon

Jason Wilder

Well-Known Member

as a belt cleaner i use a silicone tube that was left open to dry, just cut the plastic tube and you have a great belt cleaner.

I just tried this and it works great! Thanks for the tip.

Jason

Doug Lester

Well-Known Member

I use some oblong rare earth magnets to hold small pieces for grinding. Of course it only works with ferrous metals but it helps prevent sanding off your finger tips trying to grind small parts on your grinder. If the magnets are large enough to hold onto they're going to be strong enough to hold the work.

Doug

Doug

Mike Martinez

Well-Known Member

Back to the Basics

#1 When hand sanding and using oil based lubricants/ fluids, remember to use a degreaser prior to etching. I was trying to etch a couple of knives to bring out the hamon and could not figure out why I was getting potty results, until it hit me that the metal was absorbing this new and improved WD40 that I decided to use.

#2 Make sure you use a clean rag to wipe your blade clean in between different grits to avoid having a stray grit from the previous set scratch your progressive finish.

Hope these basic tips save someone time, I spent hours fighting these two small things for two days. :biggrin:

#1 When hand sanding and using oil based lubricants/ fluids, remember to use a degreaser prior to etching. I was trying to etch a couple of knives to bring out the hamon and could not figure out why I was getting potty results, until it hit me that the metal was absorbing this new and improved WD40 that I decided to use.

#2 Make sure you use a clean rag to wipe your blade clean in between different grits to avoid having a stray grit from the previous set scratch your progressive finish.

Hope these basic tips save someone time, I spent hours fighting these two small things for two days. :biggrin:

synthesist

Member

I just noticed this thread................... This is excellent. Lots of good, sneaky ideas in here. This deserves to be a sub-forum.

Syn

Syn

rhinoknives

Well-Known Member

My shop tip for the Day to you Dogs & Dogettes is that you go get a Tetanus shot, Or make sure your is current if you haven't got one in a few years.

My Dr gave me what that is suppose to last about 7-10 years I think?. I keep forgetting when I got it?

So Every year when I have my annual physical, I write out a list of questions on a note pad and go over it all with the doc. The Tetanus shot is always at the top of the list..

We all play with metal all day long and every you part timers need to make sure this is taking care of!

If you don't have any insurance? Check your County health services.

Sell a knife to get it done if you have too!

I was reading a book a while ago about these Americans in China before WWII and one of them got Tetanus & died, a very painful death!

So get those shots up to date.

Laurence

www.rhinoknives.com/

My Dr gave me what that is suppose to last about 7-10 years I think?. I keep forgetting when I got it?

So Every year when I have my annual physical, I write out a list of questions on a note pad and go over it all with the doc. The Tetanus shot is always at the top of the list..

We all play with metal all day long and every you part timers need to make sure this is taking care of!

If you don't have any insurance? Check your County health services.

Sell a knife to get it done if you have too!

I was reading a book a while ago about these Americans in China before WWII and one of them got Tetanus & died, a very painful death!

So get those shots up to date.

Laurence

www.rhinoknives.com/

"Cure" for epoxy

Gluing up knife handles can sometimes be a mess so I use a silicone "place mat" on top of my work bench and do all my epoxy work on it. Epoxy won't stick to it so when it has cured, I simply shake the place mat over a waste can and the all the epoxy lumps fall off and it's ready for the next job. The place mat is about 12" x 17" and approx .025" thick with a smooth finish. It's rated to over 400 deg F so I often lay my leather or Kydex sheath on it while using a heat gun. My wife purchased it at a kitchen store years ago.

Gluing up knife handles can sometimes be a mess so I use a silicone "place mat" on top of my work bench and do all my epoxy work on it. Epoxy won't stick to it so when it has cured, I simply shake the place mat over a waste can and the all the epoxy lumps fall off and it's ready for the next job. The place mat is about 12" x 17" and approx .025" thick with a smooth finish. It's rated to over 400 deg F so I often lay my leather or Kydex sheath on it while using a heat gun. My wife purchased it at a kitchen store years ago.

rhinoknives

Well-Known Member

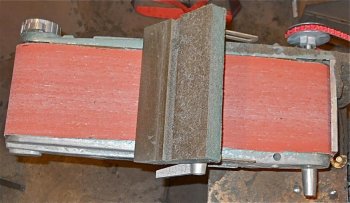

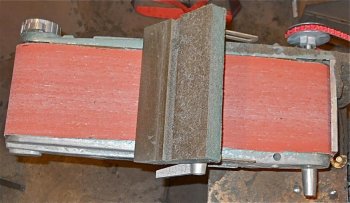

My shop tip for today is Frankenstein!

I found a old Magna/ Shop Smith 6 x48 sander a few years ago.

I always have extra motors around and with a length of belt link a couple of pulleys and a 2hp motor

I was able to sharpen several 18" long Planer blades for a knife junkie customer of mine that owns a tree trimming & removal service.

There is a adjustable tilt table for these sanders and it came in handy with this sharpening project.

It also works great for truing up blocks and scales.

I have ground knives on this beast in the past also. www.trugrit.com has Ceramic belts in 6 x 48" and many other sizes.

Laurence

www.rhinoknives.com

I found a old Magna/ Shop Smith 6 x48 sander a few years ago.

I always have extra motors around and with a length of belt link a couple of pulleys and a 2hp motor

I was able to sharpen several 18" long Planer blades for a knife junkie customer of mine that owns a tree trimming & removal service.

There is a adjustable tilt table for these sanders and it came in handy with this sharpening project.

It also works great for truing up blocks and scales.

I have ground knives on this beast in the past also. www.trugrit.com has Ceramic belts in 6 x 48" and many other sizes.

Laurence

www.rhinoknives.com

smithy

Well-Known Member

I went to auto-zone today and bought a cup holder that mounts in the car window channel. Went home and cut off the lip that goes in the channel and then screwed it to the top of my leather bench. That way I will not spill the 16 0z. coffee all over the leather I was working on like I did today.

I went to auto-zone today and bought a cup holder that mounts in the car window channel. Went home and cut off the lip that goes in the channel and then screwed it to the top of my leather bench. That way I will not spill the 16 0z. coffee all over the leather I was working on like I did today.

i need to do that..