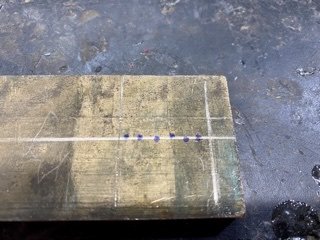

Good instructions on how to GunCote - thanks. that holder is perfect, amazingly simple, but nothing could work better. I'm sure thinking about ordering an air brush and trying that. Without sometype of treatment we all know how much a Damascus pattern can fade over time.New ferric chloride is here and I have a little time so into the etch until I like it. While the blade is etching I set up for the Gun Kote.

View attachment 82038

I begin by shaking the stuff up for five minutes. I actually set a timer and shake for 5 minutes. I had a few problems when I first started using it and that was the advice I got from KG. Since I started doing that, I have had no trouble. After the shake up, I get my air brush ready. Ed is the one who taught me how to do Gun Kote and he uses an air brush so you can adjust spray volume. I do not want the knife to look like its coated in plastic so I use a fine, fine mist so you can just see the stuff coming out.

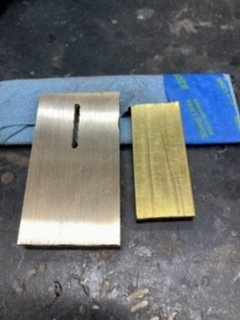

View attachment 82039

The cheapo HF one works fine. Once the knife is etched I neutralize the acid and hose it off with water. After water I flood it with rubbing alcohol and finish by blowing air from my compressor. Then spray it with the Gun Kote. I have made a simple holder so no parts of the knife are touched during the curing process. 2 hours at 300f.

View attachment 82040View attachment 82041

Into the kiln for 2 hours at 300f.

edit: I just placed an order for an air brush, and 4 oz of GunKote. I had to get "2409F flat clear" my only other choice I found was the "2409SC Super Clear" which I think was glossy. I didn't find your "satin clear" pictured above.

Last edited: