You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question on this Quenchant

- Thread starter tkroenlein

- Start date

Kevin R. Cashen

Super Moderator

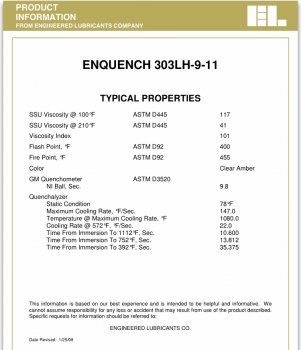

It should be a faster oil than most, but just a hair slower than Parks #50. Viscosity is very similar. This oils maximum rate is 147, Parks 50 is 198.9. The top half of the curve, through Ar1 (the pearlite transition zone) it is about 1.2 seconds slower than Parks. At the bottom of the curve it is a bit faster than needed, around 1.4 seconds faster than Parks, that is not a good thing, but the difference is so small that it shouldn't matter much.

From reading the numbers, I think this would work for any of the shallow hardening steels (10XX, W1, W2) in sections less than .187”, with some pearlite formation in thicker spines, but the edge should be good.

Please come back and let us know how this works out, if you go with it, as this looks like a possible Parks #50 alternative, at least on paper.

From reading the numbers, I think this would work for any of the shallow hardening steels (10XX, W1, W2) in sections less than .187”, with some pearlite formation in thicker spines, but the edge should be good.

Please come back and let us know how this works out, if you go with it, as this looks like a possible Parks #50 alternative, at least on paper.

tkroenlein

Well-Known Member

Thanks, Kevin!

Does this look useful for 80CrV2?

Does this look useful for 80CrV2?

Kevin R. Cashen

Super Moderator

It may be a bit fast for 80CrV2, but not as mismatched as Parks #50. If you will be working primarily with 80CrV2, an 11 to 14 second oil would be better.

tkroenlein

Well-Known Member

Thanks!

That really answers my questions about!

That really answers my questions about!

tkroenlein

Well-Known Member

Kevin R. Cashen

Super Moderator

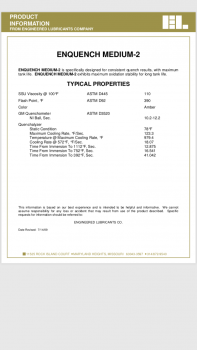

That one would be a very good match for 80CrV2.

tkroenlein

Well-Known Member

Awesome.

I'll definitely try the Medium-2, and maybe once the weather warms a bit the Enquench.

I'm not a pro but if the price is right I can do simple hardness tests on some common stuff and share here.

I'll definitely try the Medium-2, and maybe once the weather warms a bit the Enquench.

I'm not a pro but if the price is right I can do simple hardness tests on some common stuff and share here.

tkroenlein

Well-Known Member

Thought I'd offer a comment on the Enquench Medium 2, which I've been using on all the deeper hardening steels I use, 80CrV2, 52100, and 8670.

I quench almost everything unground, in stock thicknesses from around .085" to .200". I use 3 gallons of oil, in a 5" SCH 10 SST pipe with about 18" of oil and 4" of headspace.

Note that the data sheet gives the 10.2-12.2 nickel ball speed at 78F. I've used the oil at ambient temp down to about 60F and up to about "warm cup of coffee," that is to say I can comfortably put my hand in it or on the vessel. So under 140F for sure. I've noticed no I'll effects across a batch (5 medium sized max). I do hardness test each blade.

I can't directly compare this to AAA, because I've never used it, but if there is an advantage over that, it would be not having to pre-heat. I'm not sure you do have to pre heat AAA, but they do recommend it.

I am fixing to get the faster oil to use primarily for 1075. I'll report back on that as well.

I quench almost everything unground, in stock thicknesses from around .085" to .200". I use 3 gallons of oil, in a 5" SCH 10 SST pipe with about 18" of oil and 4" of headspace.

Note that the data sheet gives the 10.2-12.2 nickel ball speed at 78F. I've used the oil at ambient temp down to about 60F and up to about "warm cup of coffee," that is to say I can comfortably put my hand in it or on the vessel. So under 140F for sure. I've noticed no I'll effects across a batch (5 medium sized max). I do hardness test each blade.

I can't directly compare this to AAA, because I've never used it, but if there is an advantage over that, it would be not having to pre-heat. I'm not sure you do have to pre heat AAA, but they do recommend it.

I am fixing to get the faster oil to use primarily for 1075. I'll report back on that as well.

jmforge

Well-Known Member

Not having to preheat under normal conditions is a big plus, just like with Parks 50.Thought I'd offer a comment on the Enquench Medium 2, which I've been using on all the deeper hardening steels I use, 80CrV2, 52100, and 8670.

I quench almost everything unground, in stock thicknesses from around .085" to .200". I use 3 gallons of oil, in a 5" SCH 10 SST pipe with about 18" of oil and 4" of headspace.

Note that the data sheet gives the 10.2-12.2 nickel ball speed at 78F. I've used the oil at ambient temp down to about 60F and up to about "warm cup of coffee," that is to say I can comfortably put my hand in it or on the vessel. So under 140F for sure. I've noticed no I'll effects across a batch (5 medium sized max). I do hardness test each blade.

I can't directly compare this to AAA, because I've never used it, but if there is an advantage over that, it would be not having to pre-heat. I'm not sure you do have to pre heat AAA, but they do recommend it.

I am fixing to get the faster oil to use primarily for 1075. I'll report back on that as well.

Andre Grobler

Well-Known Member

i am jealous... you get spec sheets with your quench oil...

Doug Lester

Well-Known Member

I don't know if I would consider 8670 a deeper hardening steel. The data that AKS lists for it, though I'm a little unsure of it, shows it being quenched in Parks 50.

Doug

Doug

jmforge

Well-Known Member

I would say the same for 52100. IIRC, Mr. Cashen determined that medium fast oil like AAA was the preferred method for quenching that steel as opposed to salt which he uses for the deep hardening steels like O1 and L6. I think that we tend to not think about the 20 second oils much, but decide between Parks 50 and AAA and their analogues from other companies. So what we are talking about is not fast and slow oils but pretty fast and darn fast ( and with many steels TOO fast ) oils. What I need to figure out is how deep hardening Cru ForgeV is. It is probably deeper than 52100, but maybe not quite "air hardening" like L6 or O1 can be. I know that people have used it a mix with 15N20 but I recall hearing that Adam Desrosiers, who has as big a pile of CFV as anyone out there, found that L6 worked better.I don't know if I would consider 8670 a deeper hardening steel. The data that AKS lists for it, though I'm a little unsure of it, shows it being quenched in Parks 50.

Doug

Last edited:

tkroenlein

Well-Known Member

8670 is the "deepest" hardening of the bunch I listed. On paper anyway.

I said "deeper" in comparison to shallow hardening steels like 10xx and W's. I do believe those steels that I listed are all properly classified as "deep hardening."

Is Duratherm 48 comparable to AAA? That's what Enquench M2 is comparable to.

I said "deeper" in comparison to shallow hardening steels like 10xx and W's. I do believe those steels that I listed are all properly classified as "deep hardening."

Is Duratherm 48 comparable to AAA? That's what Enquench M2 is comparable to.

jmforge

Well-Known Member

The DT 48 seems a fast oil like the faster Enquench stuff that was originally posted. Maybe not quite as fast as 50 or the Houghton equivalent, but faster than AAA. The Houghton "medium fast" that is or was repackaged as Brownells Tough Quench and the funky cloudy McMaster Carr stuff all seem to be similar to AAA. Those are fast enough to work on most 1084 in my experience because 1084 has higher manganese content than say 1095 or even 1075.8670 is the "deepest" hardening of the bunch I listed. On paper anyway.

I said "deeper" in comparison to shallow hardening steels like 10xx and W's. I do believe those steels that I listed are all properly classified as "deep hardening."

Is Duratherm 48 comparable to AAA? That's what Enquench M2 is comparable to.