You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

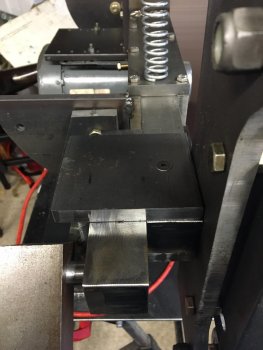

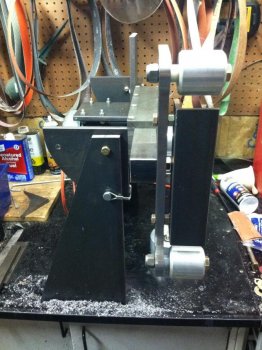

Question on my grinder build (Almost done)

- Thread starter JawJacker

- Start date

EdCaffreyMS

"The Montana Bladesmith"

Just a bit of advice when mounting a gas strut on a grinder..... mount it with the rod portion/seal facing downward. A couple of years ago I had three of them fail on me within two months.... I finally figured out that all the steel dust/grit of grinding was getting to the to seal and destroying it (at the time I was mounting them with the rod/seal facing up). When I mounted them with the rod/seal facing down, it took almost a year before the seal went, and it failed.

I've since gone back to the typical spring..... never had one of those fail.

I've since gone back to the typical spring..... never had one of those fail.

JawJacker

Well-Known Member

Ed, as I was reading your post I though, I wonder if a large wire shrink wrap would work just cut it long and heat the 2 ends to seal them. just a though.

Is the best place for a spring Mcmaster what poundage??

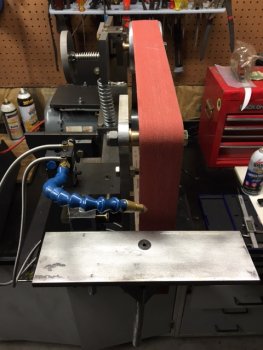

NCbiker, do you have many belts break @60lbs. I also have it setup to wet grind wondering how that will affect belt life @ 60lbs

Thanks David

Is the best place for a spring Mcmaster what poundage??

NCbiker, do you have many belts break @60lbs. I also have it setup to wet grind wondering how that will affect belt life @ 60lbs

Thanks David

scott.livesey

Dealer - Purveyor

not sure which grinder you are building. I have a Wilmont LB1000 with an adjustable tooling arm that has 2 small wheels with the platen in between. by moving the tooling arm, I can adjust for any belt tension I want regardless of the spring rating.

JawJacker

Well-Known Member

Scott, Im not a metal guy, I have taken a few ideas from different grinders out there Im further along than the pic. The idea I have is KMG, tag 101 style for the tension arm, rear pulling spring or top shock or spring may just do a spring.From reading I see most tracking problems are solved with heavy tension. Question is how much?

NCbiker, do you have many belts break @60lbs. I also have it setup to wet grind wondering how that will affect belt life @ 60lbs

Thanks David

I've been running with 60# for over a year and never had a belt break. I also run wet when I'm grinding post HT, again no problems.

EdCaffreyMS

"The Montana Bladesmith"

Ed, as I was reading your post I though, I wonder if a large wire shrink wrap would work just cut it long and heat the 2 ends to seal them. just a though.

Is the best place for a spring Mcmaster what poundage??

Got back to the thread a bit late!.... Ya know, I think if a guy could rig up some type of "boot" or "protector" for the exposed rod/seal, that just might be the answer..... I'd not thought about doing that! That might just be a reason to give the struts another chance in my shop!

It might make you laugh.... but all the springs on my grinders came from the local Ace Hardware store. I used the original springs as a reference. I had no idea what the poundage was, so I just visually picked the springs I'm using based on the wire diameter, spring diameter, and overall length... and picked springs that looked a bit "heavier".

Frank Niro

KNIFE MAKER

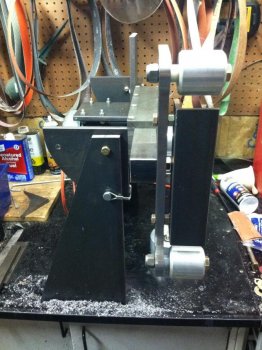

Boy, that's one study looking machine well done.

Frank

Frank

Navin_R_Johnson

Active Member

The weight of your spring will depend on how far from the pivot it's mounted. Just like a longer wrench will give you better torque because your hand is farther from the pivot.

Compare that pivot/sprig distance to a few known designs and you should be able to get a good guess for a spring weight.

Compare that pivot/sprig distance to a few known designs and you should be able to get a good guess for a spring weight.

JawJacker

Well-Known Member

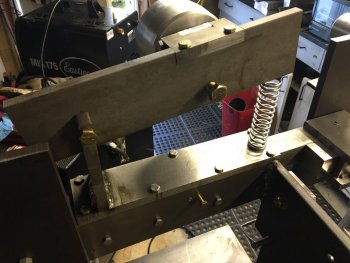

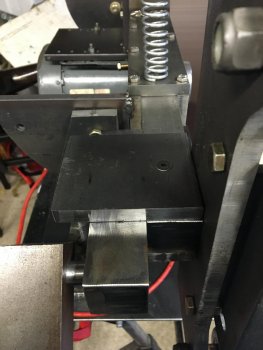

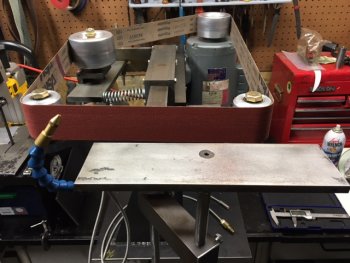

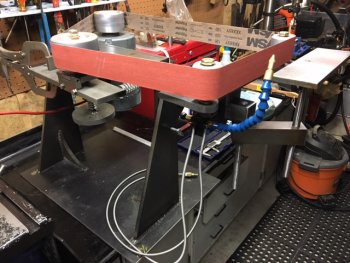

All that 1/2 in. has to have me around 150 lbs so far plus I need a 16x22'' bottom mount plate and the tracking arm. Im changing the work rest to cold rolled 1/2x4x13. I do like how tall I have it set Im 6'3 keeps my neck and back straight.

Boy, that's one study looking machine well done.

Frank

JawJacker

Well-Known Member

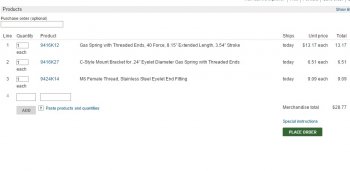

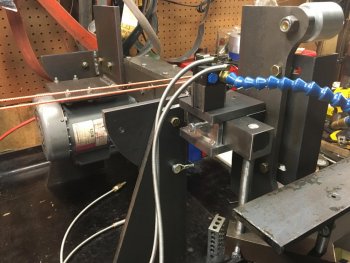

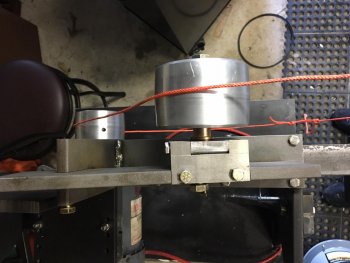

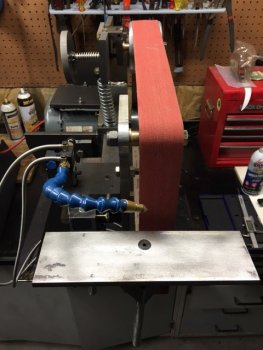

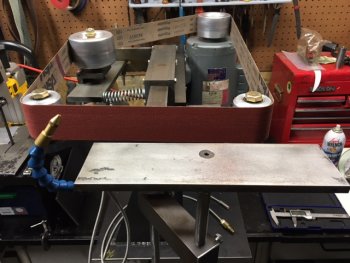

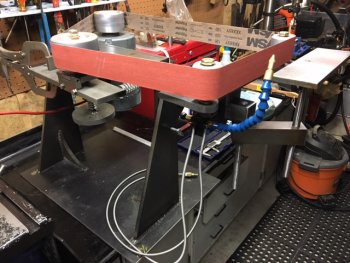

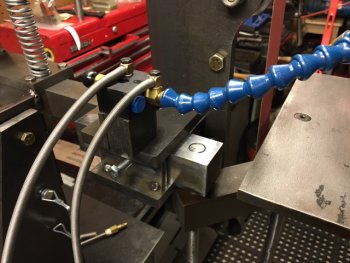

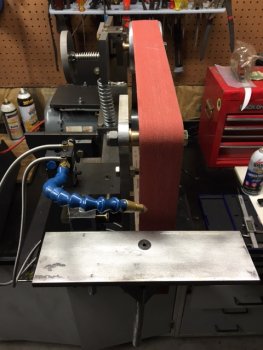

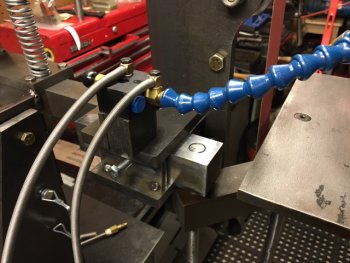

95% done

Tracks well, belt is tight doesn't wander with pressure I took the platen off gluing the glass on now. Tension spring is just sitting in there (for now) think Im going with a shock. This thing is freakin heavy, smooth and relatively low noise. Its going on a low cart. I should be wrapping this up soon, Ive been busy as hell lately I started this I think it was Oct. well worth the wait. Just want to thank everyone for the info and advise I received here. I hope the posts help someone down the line. I think if you can cut weld and drill, these grinders are relatively simple to make.

Tracks well, belt is tight doesn't wander with pressure I took the platen off gluing the glass on now. Tension spring is just sitting in there (for now) think Im going with a shock. This thing is freakin heavy, smooth and relatively low noise. Its going on a low cart. I should be wrapping this up soon, Ive been busy as hell lately I started this I think it was Oct. well worth the wait. Just want to thank everyone for the info and advise I received here. I hope the posts help someone down the line. I think if you can cut weld and drill, these grinders are relatively simple to make.

Attachments

Last edited:

Self Made Knives

Well-Known Member

Looks great! I see elements of other designs incorporated all into one, obvious you researched this a lot. How about a video tour when you get it all wrapped up?