MTBob

Well-Known Member

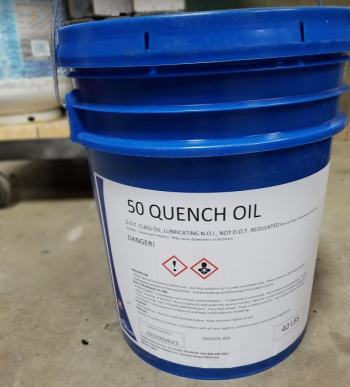

I'm finally going to get serious about quenchant. I got some Parks 50 and decided that a new tank was needed. I could buy one, but that's no fun... and they won't be built like I want. Since I don't know from noth'in about quench tanks, I just noodled up something seems like it should work, like this:

Because I'm a small volume maker, I don't think I need more than 2 1/2 gallons of oil to quench a few knives at one time. And, since Parks oils are priced better in 5 gallon containers, I figured splitting that amount in half would be about right for a tank. Like many of my shop tools, this one needs to be on castors. I've made room on the base to add another tank, and I might even consider adding a horizontal tank for differential HT.

I used 5" x 1/8" plate for the sides, plenty wide for any kind of knife I'll make. There is an angled bottom baffle to allow for draining through a 3/8" ball valve. This design holds exactly 2.5 gallons with 1" clearance at the top, and provides about 24" maximum depth.

Next I'll add a hinged top cap.

It's a simple build:

Because I'm a small volume maker, I don't think I need more than 2 1/2 gallons of oil to quench a few knives at one time. And, since Parks oils are priced better in 5 gallon containers, I figured splitting that amount in half would be about right for a tank. Like many of my shop tools, this one needs to be on castors. I've made room on the base to add another tank, and I might even consider adding a horizontal tank for differential HT.

I used 5" x 1/8" plate for the sides, plenty wide for any kind of knife I'll make. There is an angled bottom baffle to allow for draining through a 3/8" ball valve. This design holds exactly 2.5 gallons with 1" clearance at the top, and provides about 24" maximum depth.

Next I'll add a hinged top cap.

It's a simple build: